Reducing

Risk

on the Jobsite and the Balance Sheet with Live Field Data

Learning how to effectively manage risk can determine whether or not your project is successful—or fails.

By Mike Merrill

Risk is an inherent aspect of the construction business, and managing it effectively is what separates successful projects from projects that fail. As it is, the majority of projects teeter on the edge of reasonable profitability. With so little room for error, construction leaders can’t risk mistakes in labor-management, safety precautions or botched data collection reporting that negatively affects job costing and project timelines. Fortunately, technology can help.

According to WorkMax’s Live Field Data Usage report, most contractors can improve their risk management efforts by implementing a proper data management solution—a move that can directly improve their bottom line in the short and long term. With a construction landscape that is more competitive than ever, live field data is the key construction leaders have been searching for.

Here are three ways a data management solution helps construction leaders harness live field data from job sites to mitigate risk:

Labor Management

Labor is one of the most integrated parts of a job site and consumes a considerable portion of the overall project budget. It determines the productivity of each task and is the only asset that can be injured or killed. The workforce is also the part of the job site most open to unplanned risk, such as injury, errors, infringed labor laws, skilled labor shortages and over or under utilization.

Live field data buttons up labor-management and minimizes the risks to the job site in four different ways:

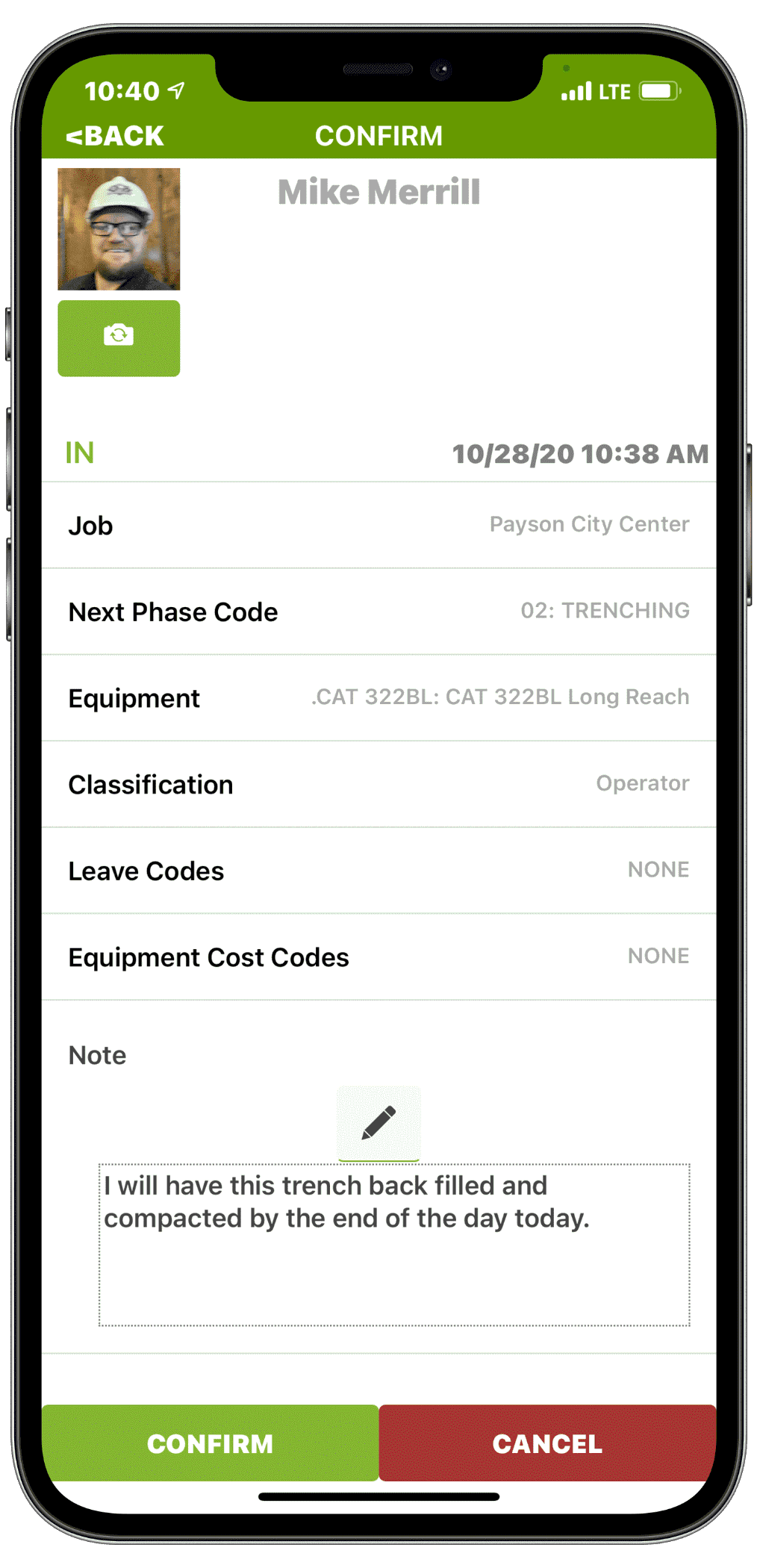

Real-time capture: Live field data removes the guesswork from start and stop times of a shift. An employee simply clocks in, selects the task they will be working on, and the application automatically takes their picture when they confirm their selection. This process does not interrupt the worker from getting to work or clocking in. When a supervisor knows they have the right person clocking in and out and have accurate labor costs in real-time, they have confidence in the data and can keep their eyes more focused on the other aspects of the project budget.

Internet connection is not required: A lack of connection only delays the reporting of the clock in and out process for a live field data app. The app collects the data as it's entered and stores it on the worker’s mobile device and uploads it the next time synchronization occurs and the internet or cell service is reestablished. This means all data is kept clean and accurate, whether there’s an internet connection or not.

Time is marked with GPS data: Supervisors can manage multiple sites at the same time with GPS and geofence tracking and management. Supervisors also need to know that the employees are clocking in and out while they are at the job site. This means that if an employee clocks in and out without being on-site of the project in reference, the program will flag the action for review. Using GPS tracking and geofencing, combined with face recognition, the project’s productivity will increase because there aren’t any hours allocated to the project when the employee is not actually working onsite.

Increased access to quality data: Today, the construction industry is going through a productivity overhaul driven by increasing the quantity of quality information. With the increase of more accurate data, the Dodge Smart Market Report says contractors can expect an increase in their ability to complete projects on or under budget, leading to expanded productivity and greater profitability. There is a clear connection from the increased quality of the information and a more effective workforce and healthier bottom line.

Photo courtesy of WorkMax

Safety Management

The National Safety Council reported that a medically inspected injury costs a contractor an average of $42,000. Work-related injuries cost the construction industry $170.8 billion in 2018. Taking $42,000 out of a project’s profit and removing a skilled worker from the job site can really cut into the bottom line. On top of those numbers is the fact that every injury is sustained by a person, leading to a moral duty to protect the job site.

Live field data empowers the entire workforce to protect themselves and the business with:

Instantaneous reporting and prompts reduce unseen safety risks: Instant communication between management and the boots on the ground allows construction companies to respond to any situation as quickly as possible, limiting the job site’s exposure to risk, problems, or errors. Instant responses will keep employees safer and, in turn, decrease the risk and costs associated with injuries.

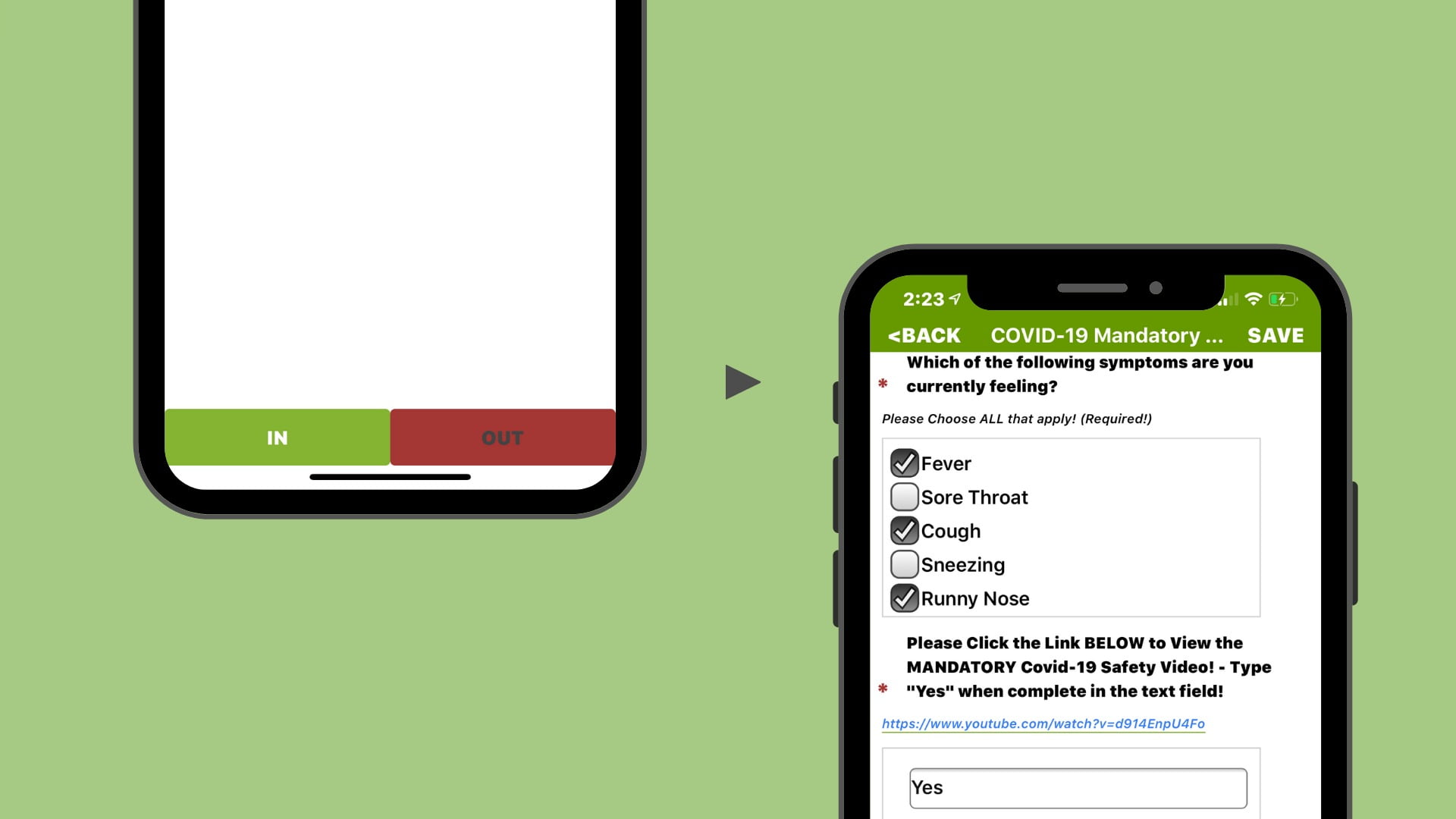

Requiring safety forms at clock in or out increases worker engagement: Live field data built with integrated workflows can trigger relevant screening forms to pop up when employees clock in on their mobile apps. This ensures that contractors achieve total reporting compliance from employees on job sites. The data takes only seconds to record and can be automatically emailed to anyone who needs access to the information immediately. Contractors can then assess the collected information as it comes in so they can also respond immediately, when necessary. GPS tracking of employees in a resource management solution also assists in identifying the location of a situation, or breach of protocol, so that they can avoid similar circumstances in the future.

Remote safety training with videos creates the most educated workforce: Live field data solutions provide an agile platform to quickly deploy new toolbox talks, effectively training employees on new safety procedures and other safety training information without requiring large coordinated meetings. Workers can be required to watch the videos as a part of their login procedure. Additionally, after employees complete a video or training, safety managers and supervisors will receive documentation with time-stamped employee signatures.

Coordination and Reporting

A cloud-based resource management system continually reports data to key areas of a construction business for labor hours, job costs, production, safety and asset management in real-time, all in one app. From field operations to accounting and finance, to payroll and project management, departments can use these insights to improve their business across the board.

Automated reporting and tracking: People in the field can now clearly communicate the project’s daily status using mobile forms photos with markups and immediately send them to project managers. Project managers no longer have to compile the daily log reports from multiple paper forms to share with internal and external stakeholders. They can also avoid having to dig through multiple emails with photo attachments to make sure they are using the right photos to accurately communicate the current status of the project in status meetings. Automated reporting helps the entire team stay focused on every task and project more effectively so that building and safety issues can be caught by the worker in the field, the supervisor in the mobile desk (truck) or the PM in the office or the field. Once a problem is seen, the entire team can be notified and the appropriate action can be taken promptly, keeping all parties in the know and on the same page. This also helps to avoid “over-communication” and wasted time from unnecessary status meetings.

Photo courtesy of WorkMax

Real-time earned value calculations: Another benefit of increasing communication between departments through data is achieving real-time earned value calculations (EVs). Resource management solutions with live field data give construction companies accurate real-time labor costs and up-to-the-minute quantities completed to use in their EV calculations on heavy civil projects. This provides the ability to efficiently run EV’s on a regular basis. This alerts them to red flags and helps identify positive or negative trends immediately.

Risk will always exist on the job site, and subsequently the ability to protect the bottom line. But technology is here to mitigate some of the most prominent historical risks that have plagued the construction industry for decades. Ensure that you are taking advantage of live field data that gives construction leaders the ability to protect their crews and businesses from unforeseen, but now avoidable, risks.

Opening Image Credit: dusanpetkovic / iStock / Getty Images Plus via Getty Images.

Mike Merrill is co-founder of WorkMax by AboutTime Technologies. He has 10 years’ experience as a construction and real estate entrepreneur and 18 years as a technology executive. Merrill is a host of “The Mobile Workforce Podcast,” gathering industry experts to inspire change and finding out what it takes to profitably manage mobile workforces. When he isn’t working, Merrill is an athletic outdoorsman and is spending time with his wife and four kids.