ASTM Standards

for Non-Metallic Lath, Metal Lath and Lathing Accessories Used With Exterior Portland Cement-based Plaster (Stucco)

Non-metallic or metal lath? The choice is yours. The standards differ.

By Herman Guevara and Bill Egan

Background

Exterior Portland cement-based plaster (or stucco) is a common exterior wall cladding used on virtually all types of construction and buildings. Stucco can be applied directly to solid plaster bases such as concrete, concrete masonry units, etc., or a lath which can be a non-metallic or metal material.

Lath is used primarily as a means of attachment and reinforcement particularly when stucco is used on framed construction.

Lathing accessories are used in conjunction with lath and stucco for thickness control, reinforcement, expansion/contraction, appearance, and to facilitate drainage. They also accommodate shrinkage, and serve as a plaster stop.

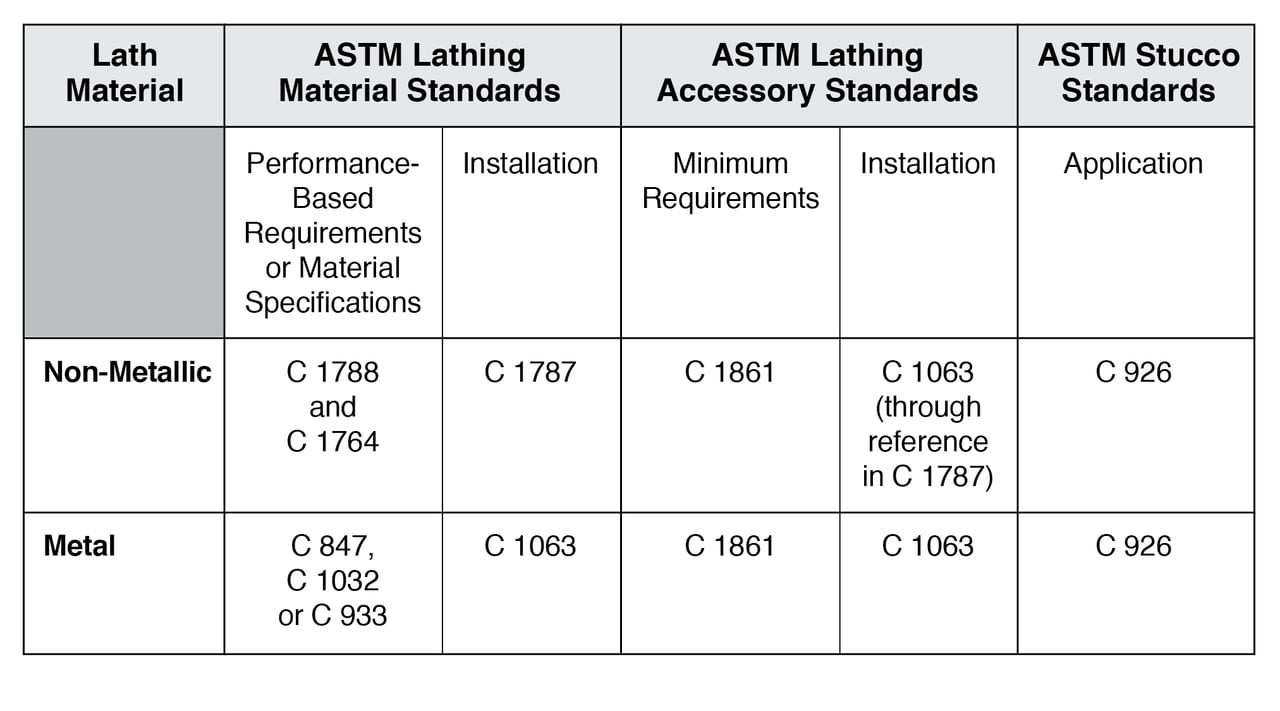

ASTM International publishes numerous standards related to materials, performance, and application of lath materials, lathing accessories and stucco. While many industry professionals recognize C 1063 and C 926, there are equally important and more recent standards include lathing accessories (C 1861) and non-metallic lath (C 1764, C 1787, and C 1788). Table 1 describes and summarizes the ASTM standards that pertain to the application of stucco.

Tabel 1 - ASTM Standards Pertaining to Stucco Applications.

Non-metallic and Metal Lath Standards

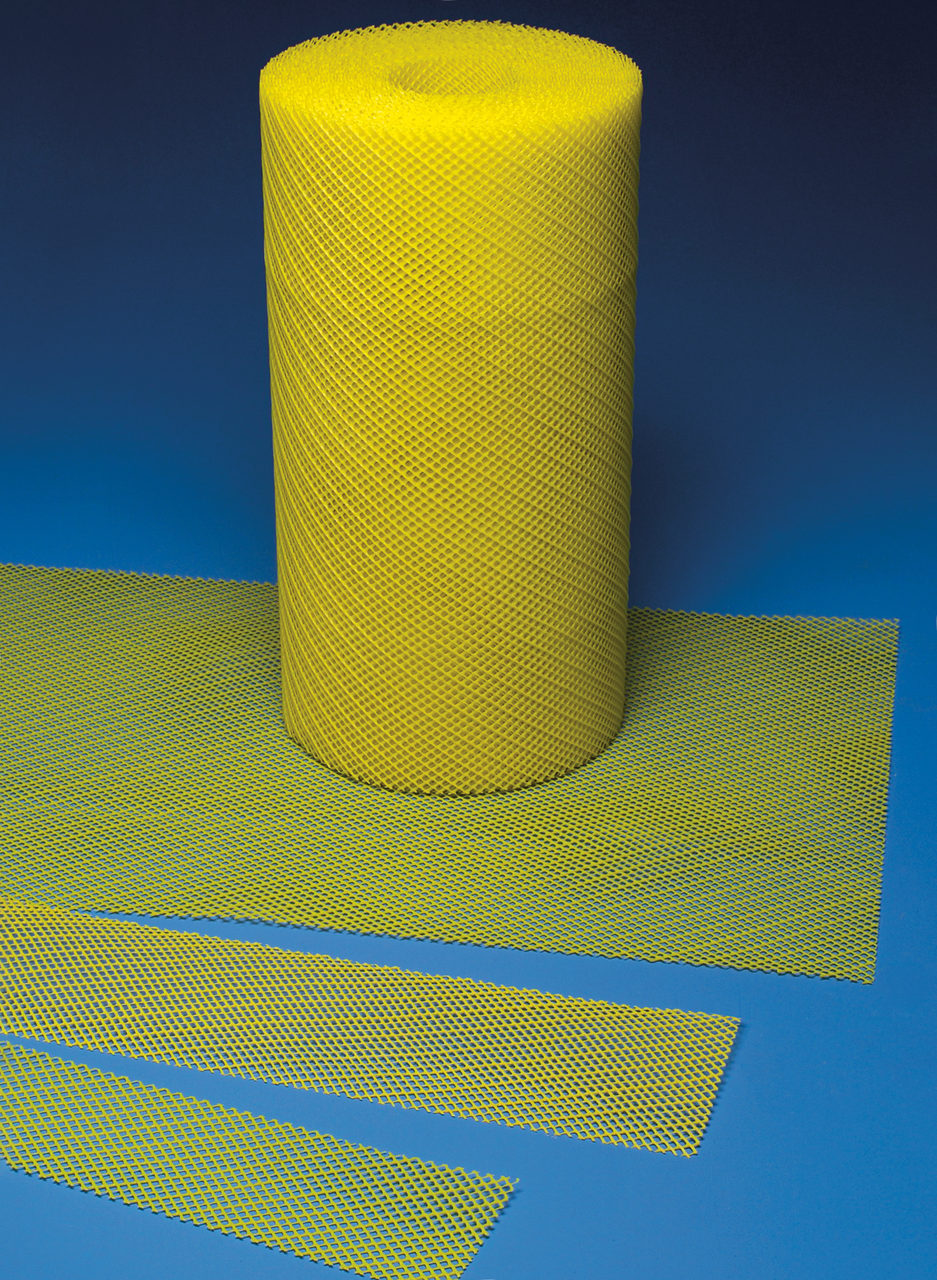

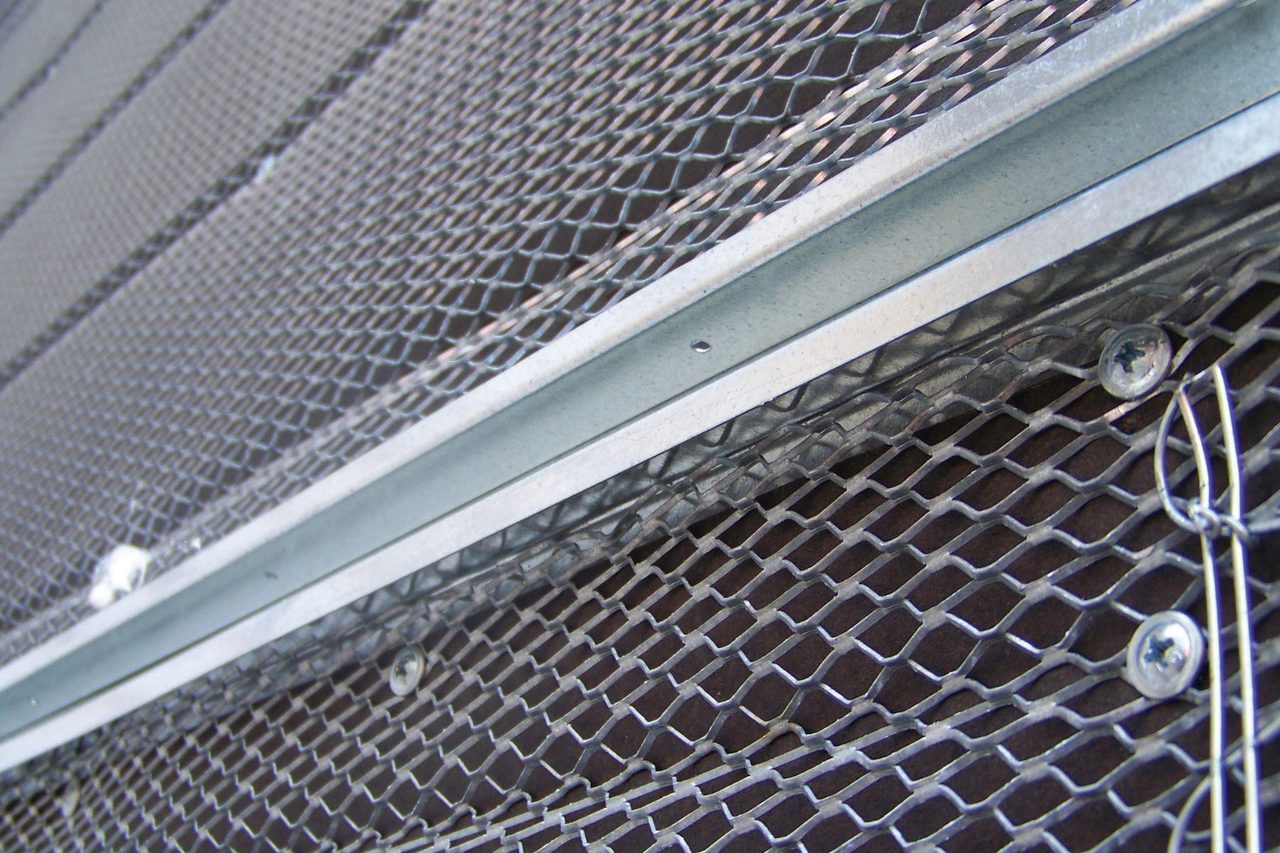

Lath is formed, manufactured or fabricated using materials known and classified as either non-metallic or metal. Common non-metallic materials and technologies include plastic and fiberglass while metal materials are typically galvanized steel but may also be available in stainless steel.

Distinct ASTM standards exist for both lath materials since non-metallic lath is based on performance standards, while metal lath utilizes material specifications. A distinction between lath materials is that non-metallics are proprietary products in terms of design and appearance, while metal materials are commonly offered in several product options that are referred to as expanded metal or diamond mesh, woven wire or welded wire lath.

Non-metallic lath material (plastic lath).

Non-metallic Lath Material (Plastic Lath)

The performance-based ASTM standards for non-metallic lath include C 1764 which specifies test methods including transverse load, vertical load, embedment, fastener pull through, etc., while C 1788 prescribes the minimum performance requirements for each test.

Metal lathing material (expanded metal lath).

Metal Material (Metal Lath)

The material based ASTM standards for metal materials include C 847 (expanded metal lath or diamond mesh), C 1032 (woven wire) and C 933 (welded wire). These standard specifications set forth minimum physical properties for each product option that may include weight, gauge or diameter, opening sizes, thickness, dimensions, etc., but do not incorporate performance requirements.

With regards to lath installation, non-metallic materials are applied per C 1787 and metal materials use C 1063.

Lathing Accessory Standards

ASTM C 1861 sets forth the minimum requirements for lathing accessories. Lathing accessories include products such as weep or drainage screeds, corner beads, control joints, expansion joints and casing beads which help facilitate the installation and performance of stucco systems. Accessories can be fabricated from steel, stainless steel, zinc alloy, anodized aluminum PVC or CPVC. The types and uses of lathing accessories are the same regardless whether the lath material is non-metallic or metal. Installation of lathing accessories is per C 1063 which is the same for both non-metallic and metal lath materials.

Exterior Portland Cement Based Plaster (Stucco) Standard

ASTM C 926 is the standard specification for the application of full thickness stucco. Included in the standard are stucco material requirements such as ingredient types, proportions, and thicknesses. In terms of plaster bases, C 926 specifies stucco application to solid plaster bases, non-metallic lath installed per C 1787 and metal lath installed per C 1063. Stucco thicknesses vary depending if applied to a solid plaster base or lathing material; however, the stucco application is the same regardless whether the lath is non-metallic or metal.

In summary, stucco is often applied to a lath material that is fabricated or manufactured using non-metallic or metal materials. As shown in Table 1, distinct ASTM standards exist for both non-metallic and metal lath materials as well as their installation. ASTM standards for lathing accessories and stucco are the same irrespective if the lath is non-metallic or metal. Refer to applicable ASTM standards for complete information regarding uses and applications.

Images courtesy of xxxxxxx.

Herman Guevara, director of Worldwide Sales for Plastic Components Inc., has more than 30 years of experience in the building materials industry. He is active on many industry boards and committees including; AWCI, FWCCA and ASTM. He can be reached at hguevara@plasticomponents.com.

Bill Egan has more than 40 years of construction experience that includes product and system design, standards development, testing, building code compliance as well as claim and construction defect investigations. He has held key technical roles with manufacturers of EIFS, stucco, air/water resistive barriers and architectural coating systems prior to establishing the Bill Egan Group (billegangroup.com), a consulting service provider for construction products and building enclosures. He serves on ASTM committees related to stucco, lath, air/water resistive barriers and is E 6.58 subcommittee chairperson for Performance of EIFS.