Trade News

Tremco CPG First on NYSERDA’s Approved Provider Lists

To set the stage for mass energy transformation of cities, the New York State Energy Research and Development Authority aims to upgrade New York’s building stock through their RetrofitNY Program. Identifying partners to help drive and execute this change, NYSERDA has named Tremco Construction Products Group an approved component manufacturer (RFQL 4551) for Deep Energy Retrofit projects across the state of New York.

Weatherproofing Technologies Inc., a general contracting and building enclosure maintenance company within Tremco CPG, has been selected as an approved solution provider (RFQL 4553). These designations make Tremco CPG the first company to serve on NYSERDA’s exclusive lists for both approved manufacturers and solution providers.

“Tremco’s ability to not only provide the innovative material solutions, but also installation of the products has us uniquely positioned to support DER project needs,” explained David Hutchinson, the Deep Energy Retrofit Development Representative for Tremco.

To improve a structure’s performance and operational costs in a sustainable manner, Tremco CPG companies emphasize restoring building components instead of replacing them wherever possible. For example, their continuous insulation panels for façades provide superior watertightness, energy-efficiency and durability for the building exterior, enabling stakeholders to achieve their long-term energy and aesthetic goals, while also minimizing tenant disruption.

EIMA Meets With OPCMIA

In June, EIMA staff members met with leaders of the Operative Plasterers' & Cement Masons' International Association to discuss ways in which the organizations can collaborate in advancing the EIFS industry.

Organized in 1864 during the Civil War, OPCMIA is the oldest building and construction trades union in the U.S. As an affiliate of North America's Building Trades Unions, OPCMIA today represents more than 50,000 plasterers and cement masons who work in numerous industry segments (including EIFS) for the purpose of protecting and promoting the quality of the industry and livelihood of its members.

Training is literally the foundation for everything OPCMIA does, and the organization operates a host of training programs that open doors of opportunity and guarantee highly skilled, safe and productive workers in dozens of chapters located throughout the U.S. and Canada. Aspiring plasterers and cement masons can earn while they learn through the OPCMIA International Training Fund’s Apprenticeship Program. High school students and recent graduates can learn valuable skills through the National Plastering Industry’s Joint Apprenticeship Trust Fund, which is OPCMIA’s partnership program with the U.S. Department of Labor’s Job Corps program.

Through its Steel Edge Women initiative, OPCMIA also encourages young women to join apprenticeship programs and strengthen their participation at all levels of the union.

Not surprisingly, members of OPCMIA have installed EIFS on many of the industry’s most important and notable projects, and OPCMIA members will continue to play a critical role in the industry and our country’s built environment.

House Adopts SWACCA-Supported Amendment

During consideration of the fiscal year 2023 National Defense Authorization Act, the House adopted by unanimous voice vote an amendment SWACCA helped to develop with Rep. John Garamendi (D-CA) that would improve construction contractors’ access to military facilities governed by the Department of Defense. Rep. Garamendi’s amendment was made part of a larger amendment package to NDAA which was adopted by unanimous voice vote.

Garamendi’s amendment is similar to the SWACCA-supported H.R. 8158, the Base Access Privileges Improvement Act, and would address mandatory background checks and credentials federal contractors and their employees must get in order to work on DOD facilities that are often “single-use” and not interoperable across DOD facilities. H.R. 8158 is intended to replace base-specific access policies with national standards set by DOD and would set forth minimum criteria for personnel vetting and determining the fitness of individuals for unescorted access to military installations. SWACCA provided significant input during drafting of the legislation, which also includes provisions:

- Requiring DOD to consider an individual’s participation in other federal security credentialing programs, such as the Transportation Worker Identification Credential and the Security Identification Display Area badge, for purposes of granting expedited, unescorted access;

- Directing that base access credentials be issued for a minimum of two years; and

- Directing DOD to examine making one installation’s access cards interoperable across other installations.

Affiliated Distributors Completes Merger With Torbsa

AD announced it has completed the merger with Torbsa Limited, a building supplies buying group in Canada, effective July 1.

The partnership creates AD Building Supplies–Canada, the fourth division in AD’s Canadian business unit. Former Torbsa President Paul Williams will serve as vice president of the new division. AD welcomes three additional new associates as part of the transaction.

“Now that we have reached the completion of the merger process, our team looks forward to working with our members to bring them new relationships and services that come from AD’s scale and history of success,” said Williams.

The merger brings 26 independent Canadian distributors with 46 locations into the AD family. Rob Dewar, president of AD Canada, said the merger will strengthen the market position of Building Supplies members and AD’s membership as a whole.

“The AD team is thrilled to officially welcome Torbsa’s employees, members and suppliers into our family,” said Dewar. “By joining forces, both our new and longtime members will be able to leverage increased buying power, and the merger gives us additional resources to explore potential new offerings to help our members grow.”

“We are thrilled to see this continued growth in Canada, which now fully mirrors our U.S. footprint in terms of distribution segments,” added Bill Weisberg, AD Chairman & CEO.

Petersen Opens Manufacturing Facility in Washington

Petersen continues to expand the reach of its trusted PAC-CLAD brand by opening a manufacturing facility in Bonney Lake, Wash. The 57,000-square-foot facility shipped its first order in May, and will be fully operational in early 2023. The facility will be equipped to provide new and existing customers in the Northwestern U.S. as well as Western Canada with PAC-CLAD steel and aluminum cladding products, including standing seam roof panels, wall panel systems, plus sheet and coil.

“Petersen’s expansion into the Northwest U.S. and Western Canada follows the success of our PAC-CLAD facility that opened in Phoenix in 2018, which has served the Northwest region and created a foundation of business from architects, specifiers and installing contractors,” said Mike Weis, Vice President of Sales and Marketing for Petersen.

“This facility will allow Petersen to more effectively serve the architectural metal cladding market in the Northwest U.S. and Western Canada,” Weis said. “We’re excited about this expansion and we’re ready to satisfy demand for the trusted PAC-CLAD architectural metal cladding products we’ve been making since 1965.” The Bonney Lake manufacturing process is overseen by Operations Manager Lance Valiquette.

Petersen’s facility is located in existing commercial space 30 miles south of Seattle and will serve customers in Washington, Oregon, Montana, Idaho, Utah, south to Fresno, Calif., plus British Columbia. The Washington location is the seventh for Petersen.

EnergyEdge and Omnis Panels Announce Partnership

EnergyEdge LLC announced that it has signed an exclusive partnership with Omnis Panels LLC to distribute EnergyEdge Permanent Insulated Concrete Edge Formwork in the U.S.

Architect R.Tom Compton developed EnergyEdge products to meet the construction market's need for concrete slab edge insulation. Omnis has a strong track record of partnering with market-leading companies and leveraging its best-in-class network to grow innovators in the U.S. market.

“We are thrilled to be EnergyEdge LLC’s partner of choice in the U.S.,” said Beau Preston, President of Omnis Panels. “Slab edge insulation is required in IECC Energy and Building codes, while almost all building performance standards promote SEI to save energy in all kinds of construction. Adding EnergyEdge to our concrete technologies products enhances our sustainable building product offerings for architects and builders.”

EnergyEdge forming systems are extruded PVC “E”-shaped rails with high-density R-10 EPS insulation and serve multiple functions.

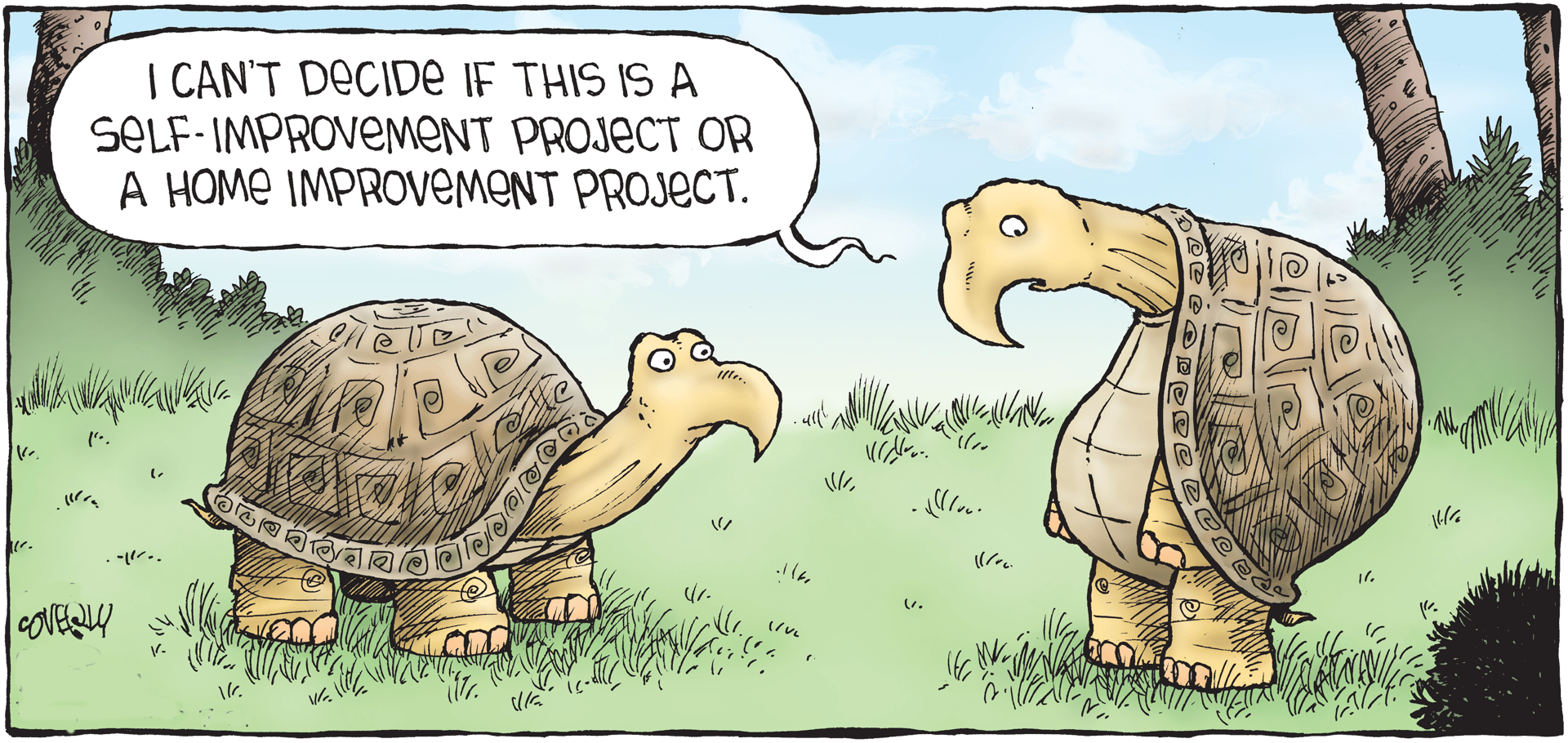

Spackle by Dave Coverly

People News

Steve Heaton has been promoted to vice president and general manager of the Atlas Molded Products Division.

iQ Power Tools has promoted Evelyn Casillas to marketing manager.

Ware Malcomb announced that Cory Adams has been promoted to director of architecture in the firm’s Irvine, Calif. office.

Sto Corp. announced that John McClellan (pictured left) has been named vice president of operations, responsible for overseeing workforce utilization, supply chain operations and ensuring a safe manufacturing process. He will replace John Yankovich, who is retiring after 17 years with the company.