The article explains that while continuous insulation with stucco improves energy efficiency and durability, it adds complexity, cost, and design challenges that require careful planning and skilled installation. By Chris K. Little

Continuous Insulation With Stucco: Benefits and Challenges

xxxxx. xxx

xxxxx

xxxxxxxxx

xxxxxxxxxxxxxxx By xxxxxxxx

h2 - xxxx

h3 - xxxx

H1 headline

Continuous insulation stands out as a key innovation in building design, offering enhanced energy efficiency by minimizing thermal bridges and simplifying compliance with energy standards like IECC and ASHRAE 90.1. However, its implementation presents unique challenges when integrating CI with stucco systems. This article explores the benefits, challenges, and practical considerations of CI, helping builders and designers strike the right balance between efficiency and constructability.

Advantages of Continuous Insulation

Thermal Barrier

The primary advantage of CI lies in its ability to create a continuous thermal barrier that reduces thermal bridges commonly found at wall studs, joints, and other structural elements. This uninterrupted insulation boosts building envelope performance by simplifying energy code compliance and reducing heating and cooling loads, which can simplify HVAC system design and sizing, potentially lowering construction costs for mechanical systems.

Flexible Material Options

CI systems offer a variety of materials, including:

- Rigid Foam Boards (e.g., XPS, EPS, polyisocyanurate): Lightweight and versatile.

- Mineral Wool: Fire-resistant and vapor permeable.

- Spray Foam: Provides both insulation and air sealing.

These options enable builders to tailor insulation solutions to specific project requirements, local climates, and budget considerations.

Challenges of CI with Stucco Systems

Moisture Management

When paired with stucco, CI requires precise moisture management. Improperly designed CI-stucco systems can lead to mold, rot, or other moisture-related issues. However, intelligently designed assemblies can act as vapor barriers or drainage planes, simplifying long-term maintenance, enhancing building durability, and reducing callbacks for builders.

However, these adjustments to cladding accessories are challenging, as current manufacturing set-ups for roll-form metal accessories aren’t produced wide enough to account for the insulation and other components included when complying with the new building energy code. This forces designers and contractors to source custom plaster accessories, increasing costs and complexity.

Increased Costs and Complexity

Implementing CI often requires:

- Thicker insulation boards

- Specialized cladding attachments, such as thermally broken clips

- Additional labor for installation

These elements collectively increase upfront construction costs, especially in retrofits where existing cladding may need to be removed and reinstalled.

While CI increases initial costs, long-term energy savings and durability often justify the investment, especially in regions with extreme climates.

Structural Adjustments

CI inevitably adds thickness to walls, impacting the structural design. Builders must account for:

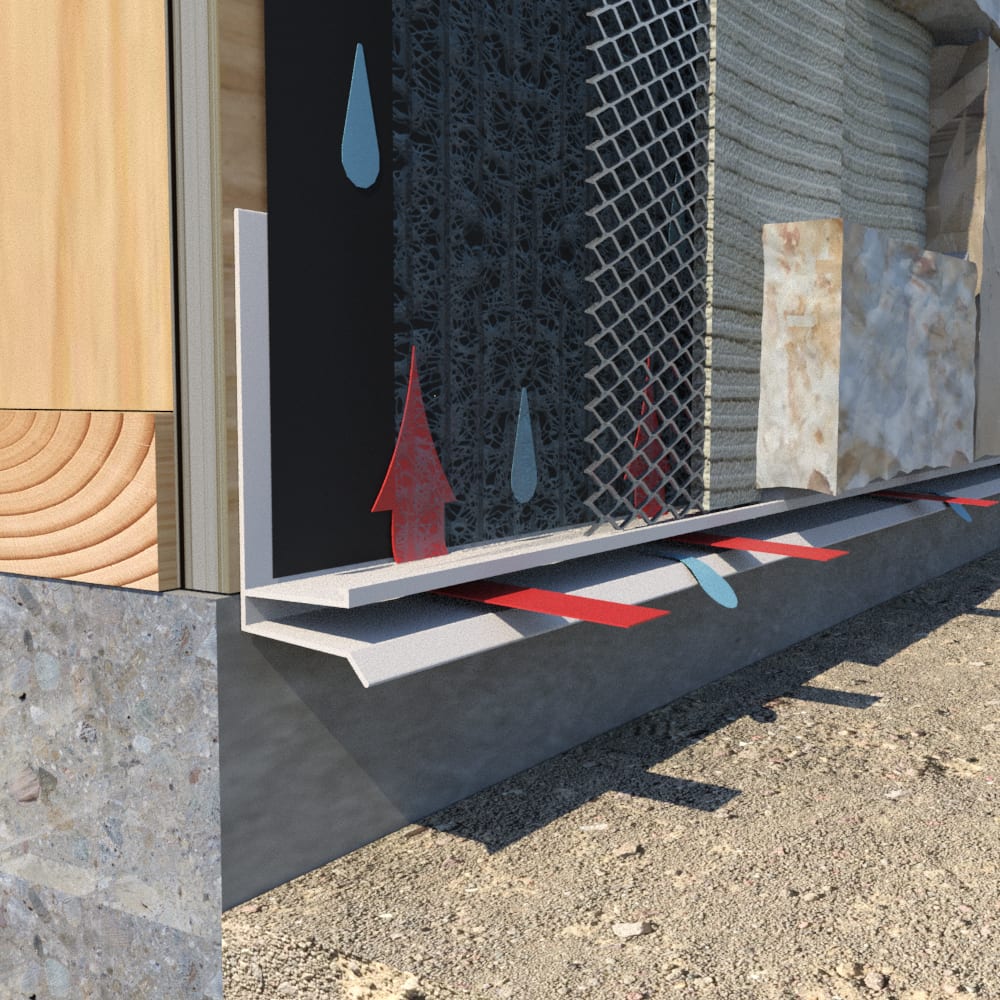

- Increased Wall Thickness: Including in foundation design, window/door detailing, and cladding systems. Drainage mats, which create a ventilated air gap for drainage and drying, must also be included into the overall thickness of the wall section for stucco.

A New Jersey office designed by Gensler, featuring a NanaWall HSW60 single-track system | Photography by Garrett Rowland Photography

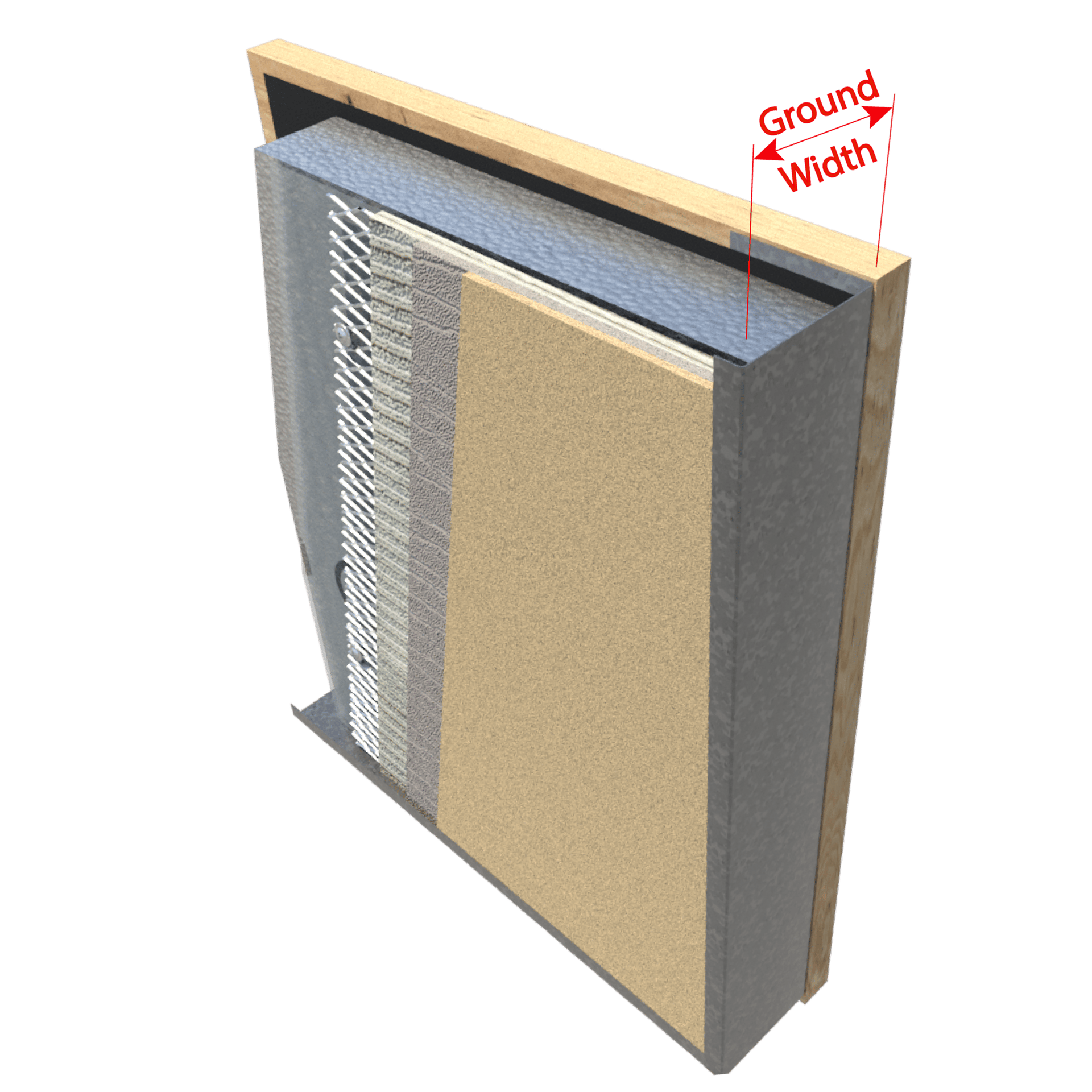

Metal or vinyl accessories will need to encompass the insulation as well as the wall cladding. Shown above (left to right) are a weep screed and a casing bead for window and door openings (jamb) with components that account for increased wall thickness.

Metal or vinyl accessories will need to encompass the insulation as well as the wall cladding. Shown above (left to right) are a weep screed and a casing bead for window and door openings (jamb) with components that account for increased wall thickness.

- Fastener Length: Attaching cladding through thick CI layers may require longer fasteners or specialized systems like thermally broken clips, which add complexity and cost. Traditional casing beads or weep screeds, which are produced today for traditional stucco thickness of 1/2, 3/4 and 7/8 inch, would not work for the CI stucco and drainage gaps, which can take that accessory width up to 1 1/8” up to 2 ½–3+ inches.

- Weight of the stucco system: The weight of cement plaster, averaging 10 to 12 pounds per square foot, also becomes a crucial factor in multi-story structures. The weight of the system will vary based on factors including thickness, type, and application method (smooth trowel versus hand-textured). Lathing reinforcement may be worth considering, as certain styles weigh much less per square foot than others.

In retrofits, CI can be harder to implement due to existing structural constraints, requiring creative solutions like thin, high-R-value materials (e.g., aerogel-based insulation).

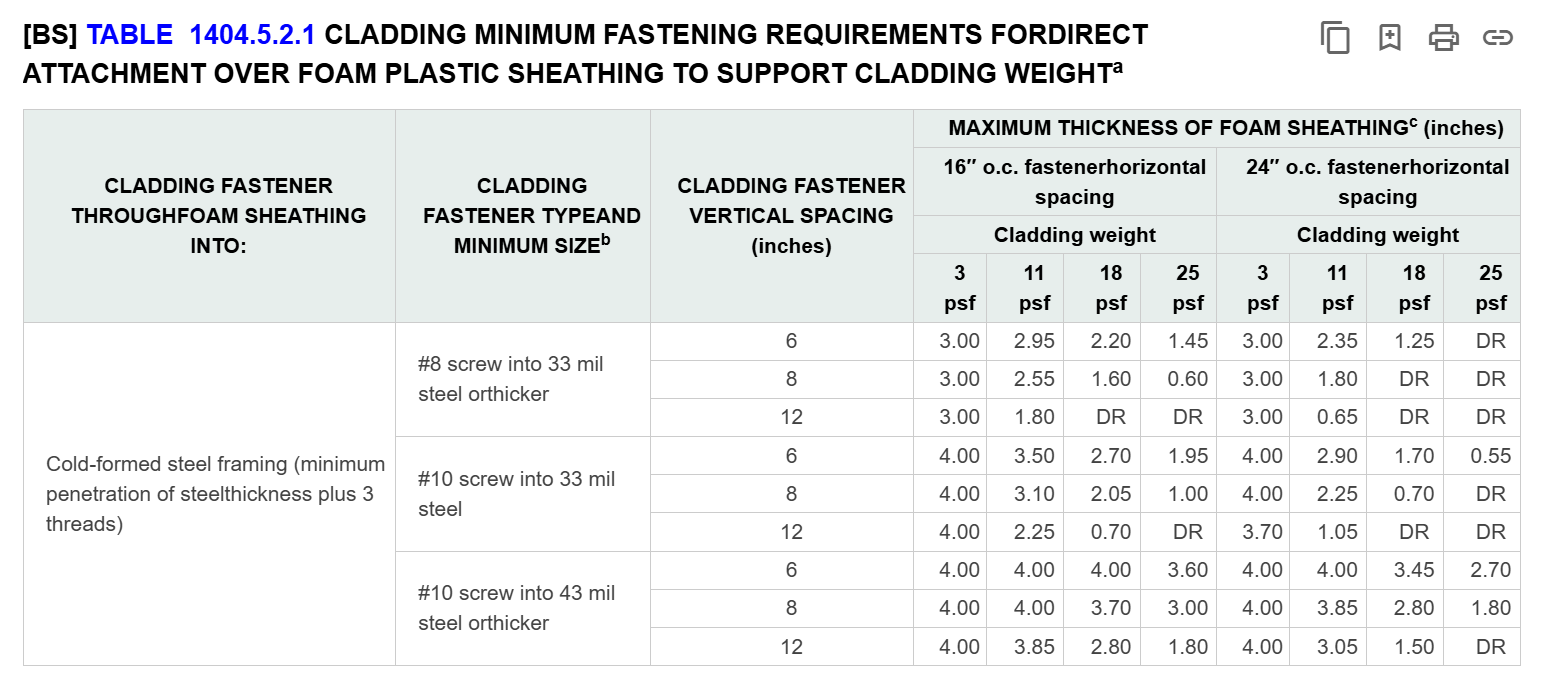

Continuous insulation design criteria are already in the International Building Code (2024 IBC Chapter 14 – Exterior Wall Coverings), where fastener loading, spacing and sizing are discussed for various insulation thicknesses. Photo courtesy of IBC.

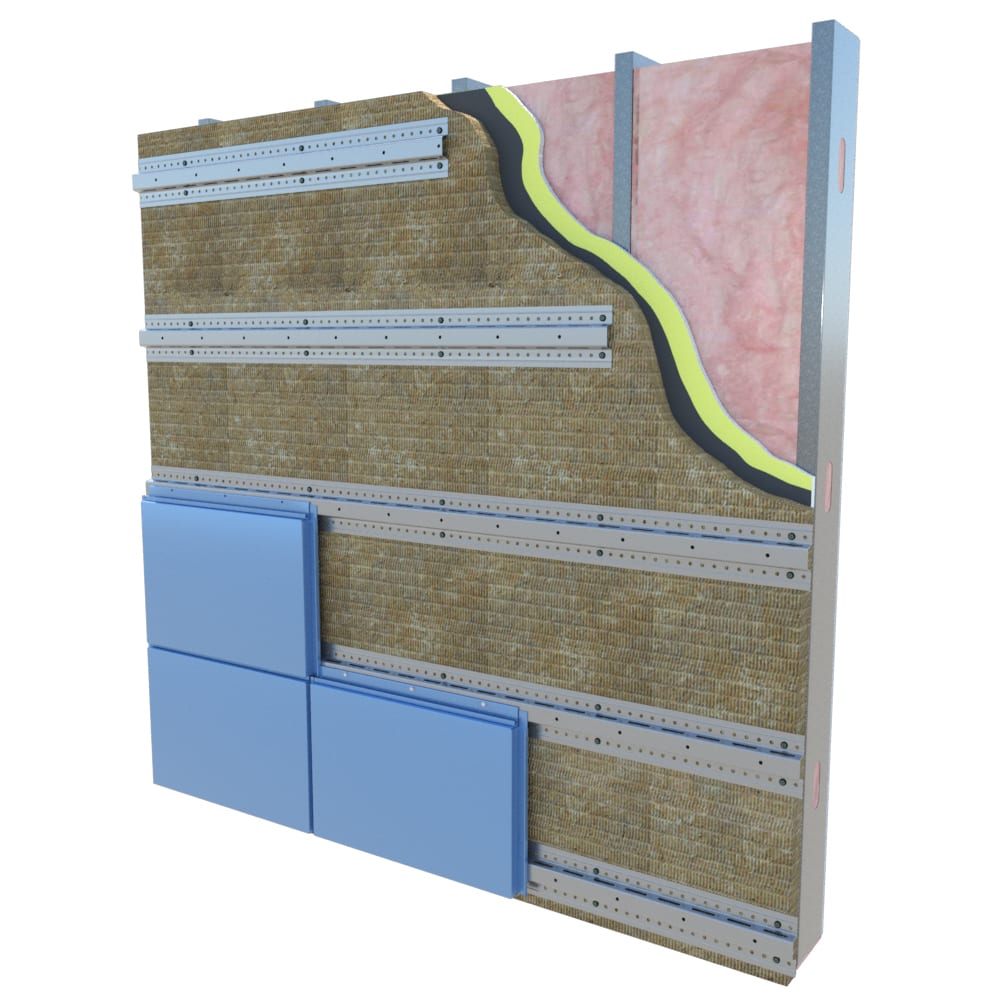

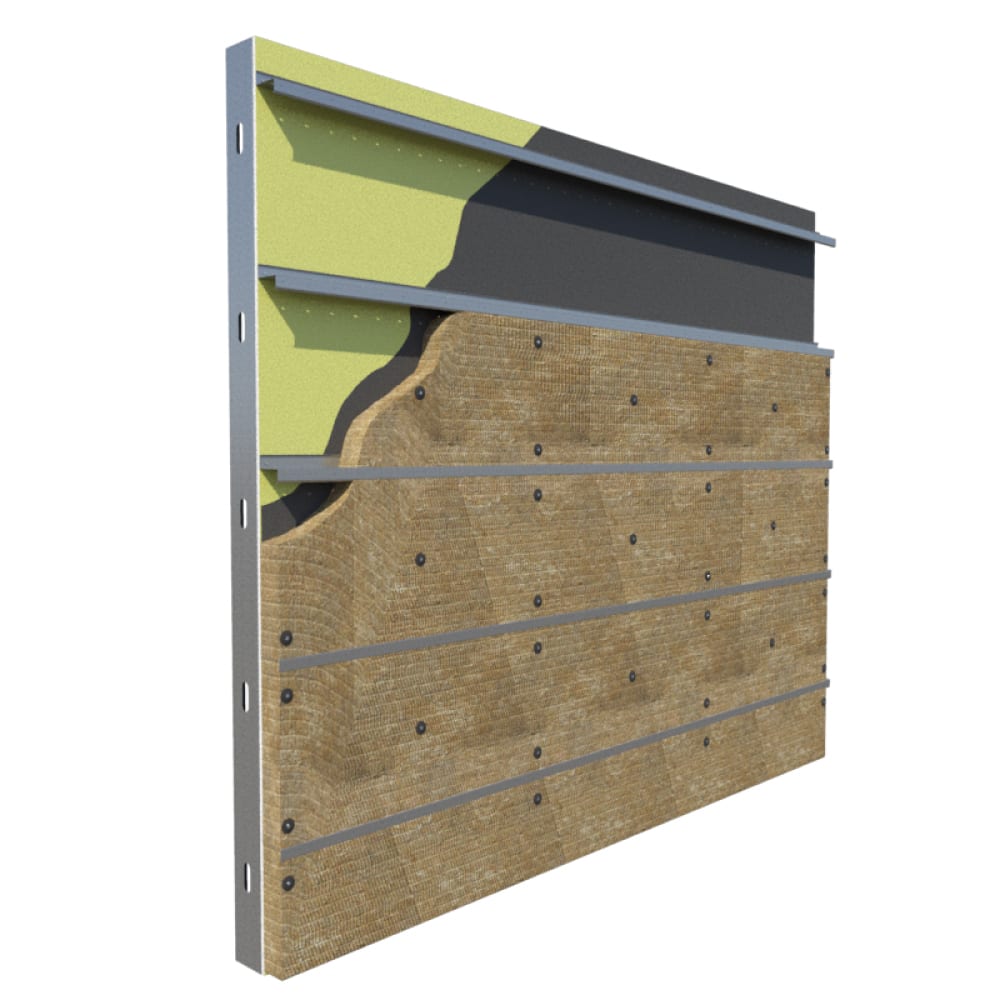

This Clip/Rail Furring system minimizes thermal transmission and provides a nice base for loading exterior claddings. Typically runs perpendicular to the stud framing.

Code and Inspection Challenges

Modern energy codes, such as IECC 2021, are driving the adoption of CI by mandating higher R-value performance. However, compliance requires careful attention to local regulations and fire resistance standards like NFPA 285. Key concerns include:

- Fire Resistance: Key criteria for passing NFPA 285 include no flame propagation to the interior of the building, flames must not exceed specific vertical and horizontal distances, and temperature thresholds must not exceed designated values. Specific insulation materials, such as mineral wool, have a more straightforward path to meeting fire code requirements.

- Permitting and Inspection: Lack of familiarity among local inspectors may cause delays and errors. Providing clear documentation and working closely with inspectors can ease this process.

Z-Furring running horizontal is a common approach to CI systems with cladding attachment, including stucco, but this creates limited thermal breaks in the insulation. Long furring strips or thermally isolated fasteners needed for CI attachment can complicate installation and require skilled labor. There are emerging components within the Clip/Rail category that are providing reduced thermal breaks while providing a healthy load-base for attaching exterior sheathing, composite panels, etc.

Practical Solutions

Early Design Coordination

Close collaboration among architects, engineers, and contractors is critical to integrate CI effectively. For example, specifying CI thickness and attachment methods during design prevents costly field adjustments. We are likely to see ASTM take on prescriptive criteria to assist manufacturers in design development.

Prefabrication Benefits

Off-site fabrication of CI-integrated wall panels can reduce on-site labor and improve quality consistency. However, precise design details are crucial to ensure proper tie-ins for drainage and moisture management during installation.

Material Compatibility

Selecting CI materials suited to the local climate and construction practices is essential. For example, vapor-permeable insulation is better for humid regions to prevent moisture buildup. Specialty accessories are being developed today to accommodate wider thicknesses.

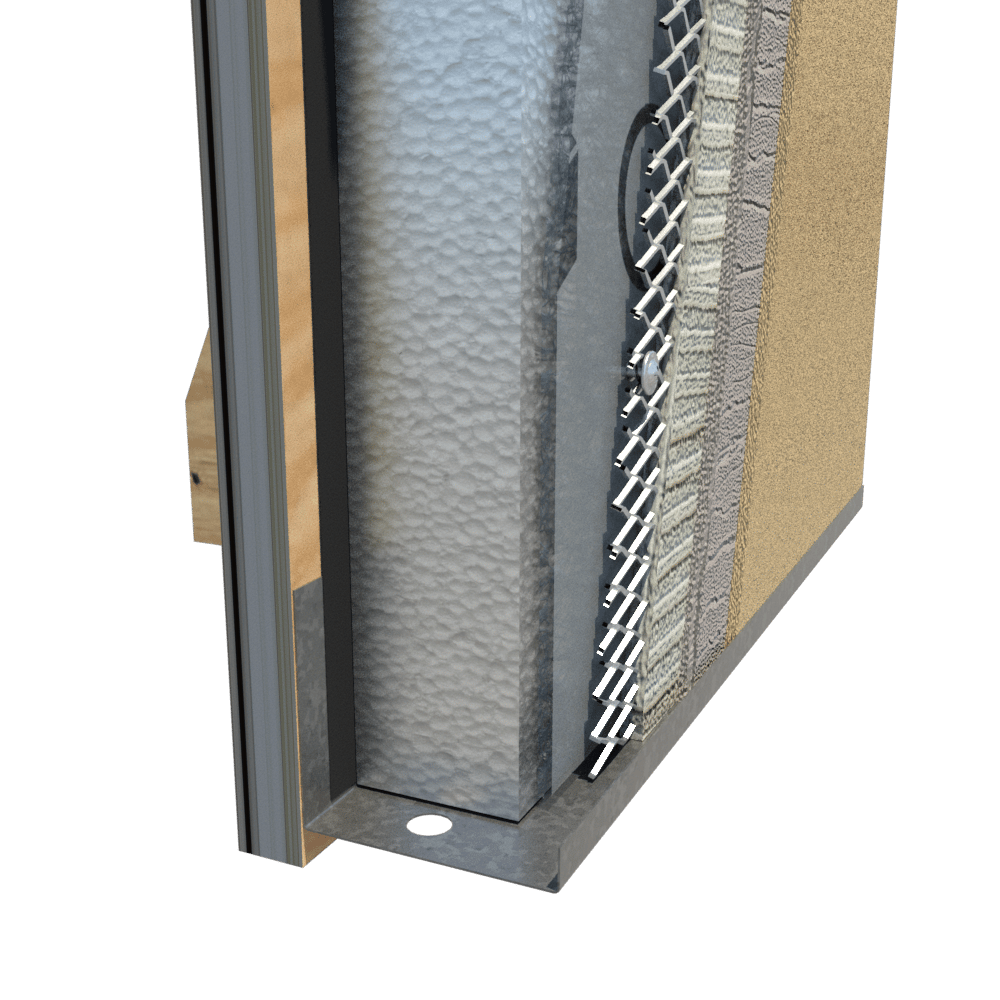

Shown is a Drip Flashing with interstitial space to permit termination of the cladding system above, while allowing draining and ventilation.

Workforce Training

Proper installation of advanced CI systems requires skilled labor. Training builders in techniques like attaching thermally broken clips and managing drainage layers ensures long-term performance and reduces the risk of callbacks.

Striking the Right Balance

Continuous insulation, particularly when combined with stucco systems, offers significant advancements in energy efficiency and durability. However, achieving these benefits requires early planning, thoughtful material selection, and skilled execution. Builders and designers should weigh the initial investment against the long-term advantages to ensure the best outcomes for their projects.

By addressing moisture control, structural integration, and code compliance, CI can transform the way we approach building envelopes, striking the perfect balance between energy performance and constructability.

All photos courtesy of ClarkDietrich; Table image courtesy of IBC

Chris K. Little is senior product manager at ClarkDietrich. He has nearly 30 years of experience in new product development and management, and has also played an integral role in helping shape industry standards for lathing, plastering and installation of masonry and stone. He can be reached at c.k.little@clarkdietrich.com.