Innovative

Lathing & Trim

Accessories

Lathing accessories—both new and old—can be used to ease lath and stucco applications.

By Bill Egan and Herman Guevara

Portland cement-based plaster or stucco is a popular exterior wall cladding used on commercial and residential buildings. Stucco is generally categorized as a one-coat system that incorporates a proprietary, manufacturer supplied basecoat or an ASTM C926 mix that may be a factory-prepared basecoat but is commonly comprised of locally sourced materials (sand, cement, etc.) that are proportioned according to the ASTM standard. The basecoat for a one-coat system is applied at a thickness up to 1/2 inch thick while ASTM C926 basecoats can be up to 3/4 inch thick. Both have an outer layer of finish coat applied over the basecoat.

Regardless of the stucco type, the basecoat is applied to lath (non-metallic or metal-based product) or a solid plaster base, such as concrete masonry unit, concrete, clay brick or tile. While stucco often relies on cavity insulation to provide the buildings thermal insulation, the system can incorporate an exterior thermal insulation layer in which case it is referred to as continuous insulation or CI stucco.

Trims

Lathing accessories, or trims as they are commonly known, are used with stucco to ease and facilitate the installation process by fulfilling one or more of the following functions:

- Serve as a screed or guide to help contractors control and achieve the stucco thickness set forth by the specifications or design professional.

- Provide moisture management by redirecting or collecting and draining incidental moisture to the exterior.

- Enable sealing and weatherproofing to other building elements.

- Minimize or reduce potential cracking through reinforcement or accommodation of movement in the stucco or supporting structure.

- Incorporate an attachment flange or key that provides alignment, connects the accessory to the lath, facilitates embedment and overall continuity of the stucco application.

- Enhance or create a desired appearance.

- Provide a means or point for the stucco to end, terminate, or transition to other building elements.

Standard or traditional lath accessories include casing beads or plaster stops, cornerbeads, control joints, expansion joints and weep screeds. Accessories are available with different ground dimensions to accommodate different stucco thicknesses which vary depending on the type of stucco and plaster base. Material options for accessories include galvanized steel, stainless steel, zinc alloy, anodized aluminum, and plastic that can be PVC or CPVC. Because of flexible manufacturing processes, plastic accessories generally offer a wide range of product options and profiles.

The selection process for an accessory generally takes into consideration local practices and preferences, cost, appearance, performance, ease of installation, desired functionality, and product availability. Minimum requirements for lathing accessories and their application are detailed in ASTM standards C1861 and C1063.

In addition to traditional accessories, there are many new, innovative products that can further ease lath and stucco installations. These innovations are primarily a result of market demand, unmet needs, industry trends, challenges, and systems such as thicker, CI Stucco that can benefit from specifically designed accessories. The following are examples and descriptions of innovative lath accessories:

Figure 2

Figure 1

Ultra Bead with Built-in Moisture Seal

Transitioning from stucco to another building element, such as a window, door, etc., typically involves terminating the stucco with a traditional casing bead and installing a sealant joint between the different products. For purposes of joint geometry, a uniform gap is formed visually or manually with a spacer or shim between the elements to allow for the sealant application. Innovative casing beads such as shown in Figure 1 incorporate a spacing flange to provide a consistent gap width in a simple and single step.

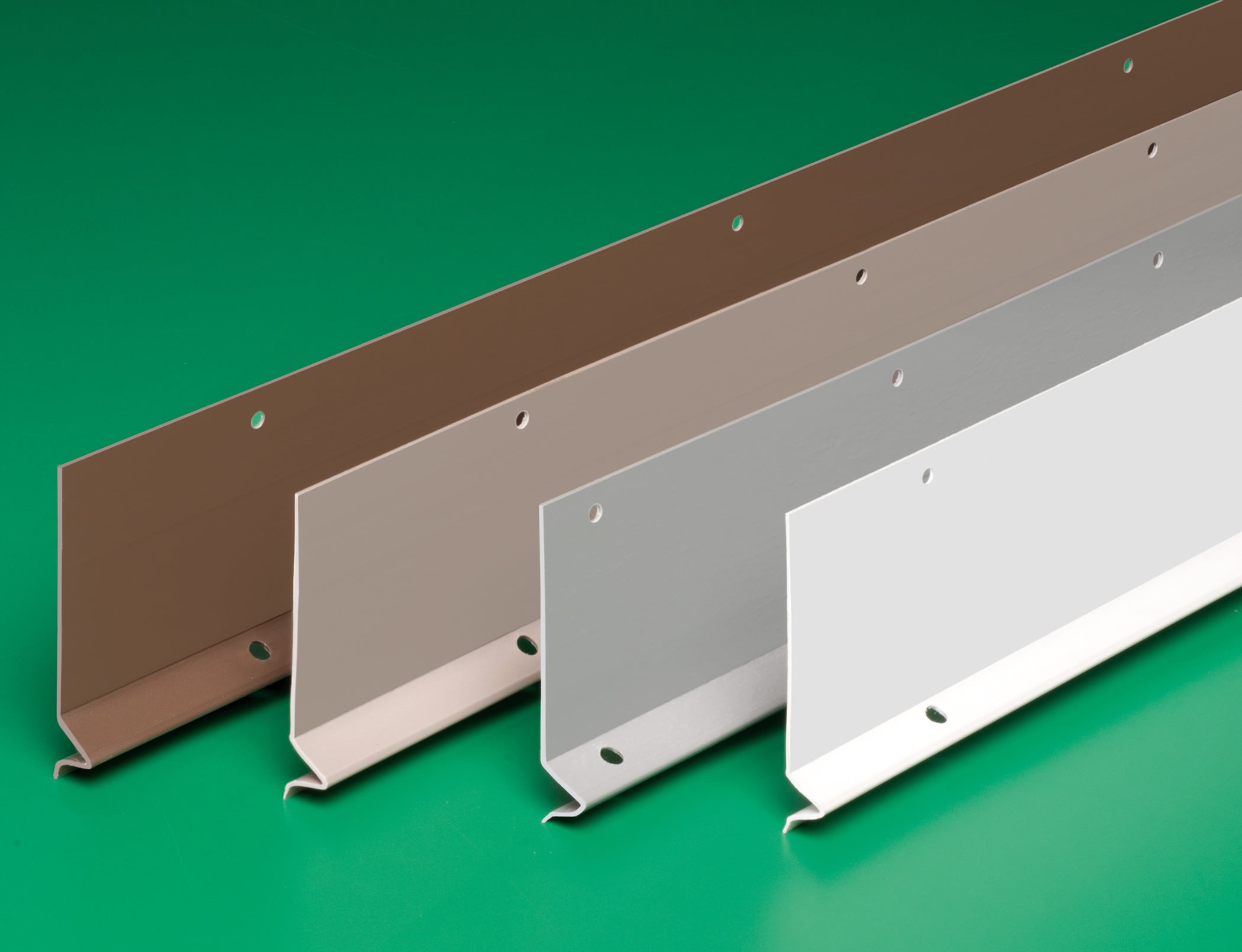

Integrally Colored Accessories

Plastic trim and lathing accessories have typically been available in white which, if desired, can be painted on site to match or complement the stucco color. Accessory manufacturers now offer integrally colored products, as shown in Figure 2, which alleviate the need for painting and further enhances the system appearance.

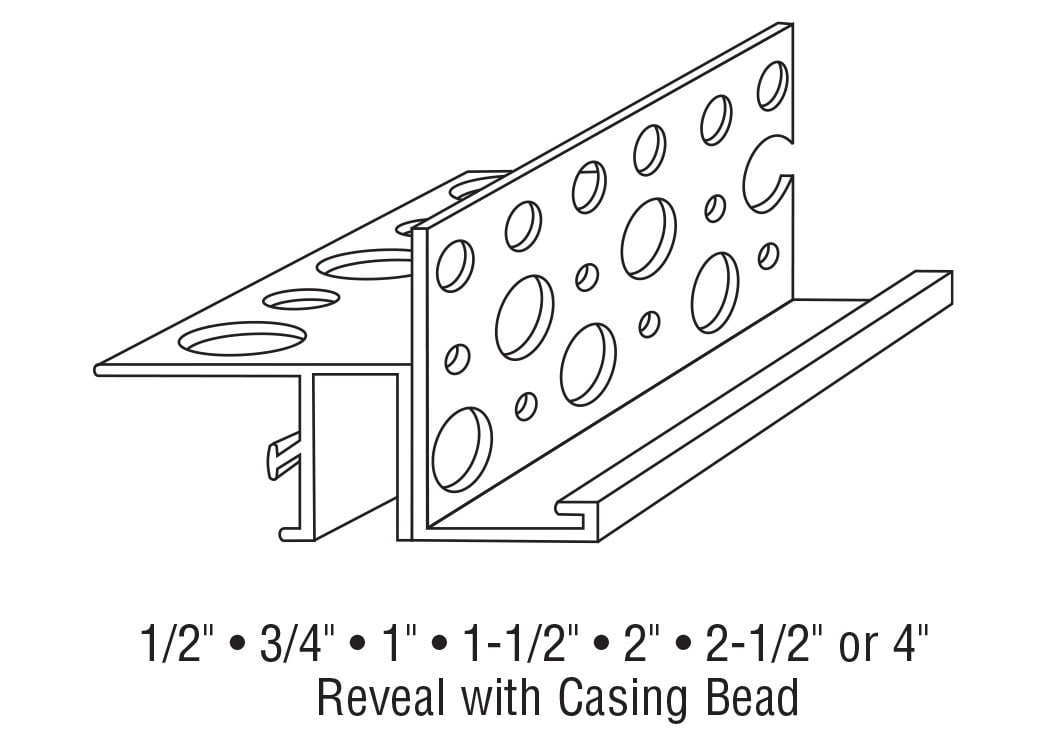

Figure 4

Figure 3

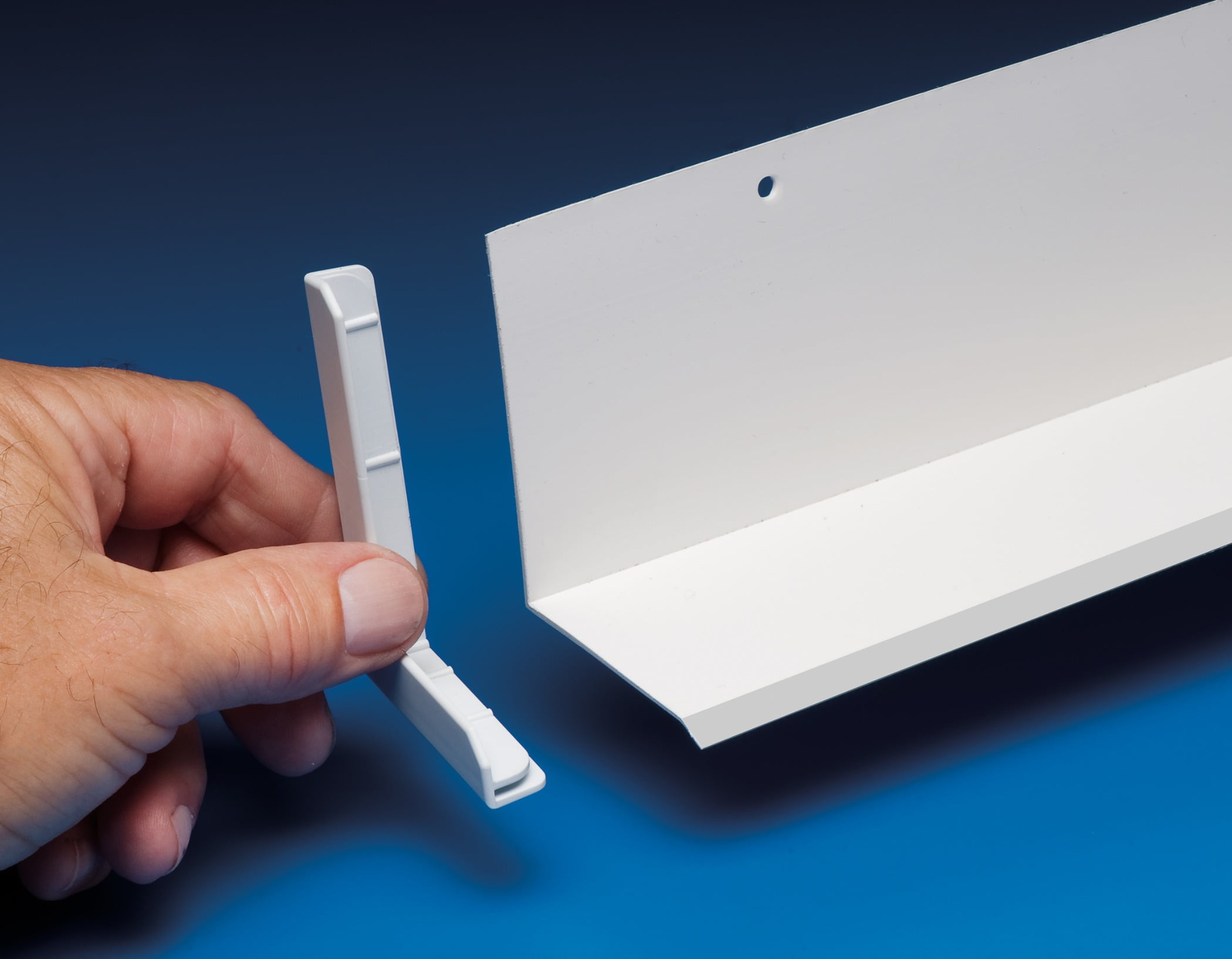

Drip Edge with End Dam Caps

Drip edges or caps are used above openings such as windows, doors, etc. to collect and redirect moisture towards the building exterior. Drip edges often incorporate end dams to capture lateral water movement along the drip edge. End dams can be a fabricated part of the drip edge or provided as a separate component. Figure 3 is an example of a manufactured end dam cap that is attached to the drip edge to form an end dam. This cost-effective solution also provides flexibility that allow the drip edge to be cut to length on the job site.

Mid-Wall Weep Screeds

On some projects, the first floor exterior walls are constructed of concrete or concrete masonry with direct applied stucco while floors above consist of framing/sheathing and stucco applied to a metal or non-metallic plaster base. Due to the dissimilar exterior wall materials, a drip edge or flashing is commonly used at the base of the framed wall to collect and redirect incidental moisture while a second accessory, such as a casing bead, is used to terminate the top of the stucco on the masonry wall. Complexity and labor can be reduced through use of a single piece, mid wall weep screed, as shown in Figure 4 which provides a means to weep incidental moisture from the upper wall and terminate the stucco on the lower wall.

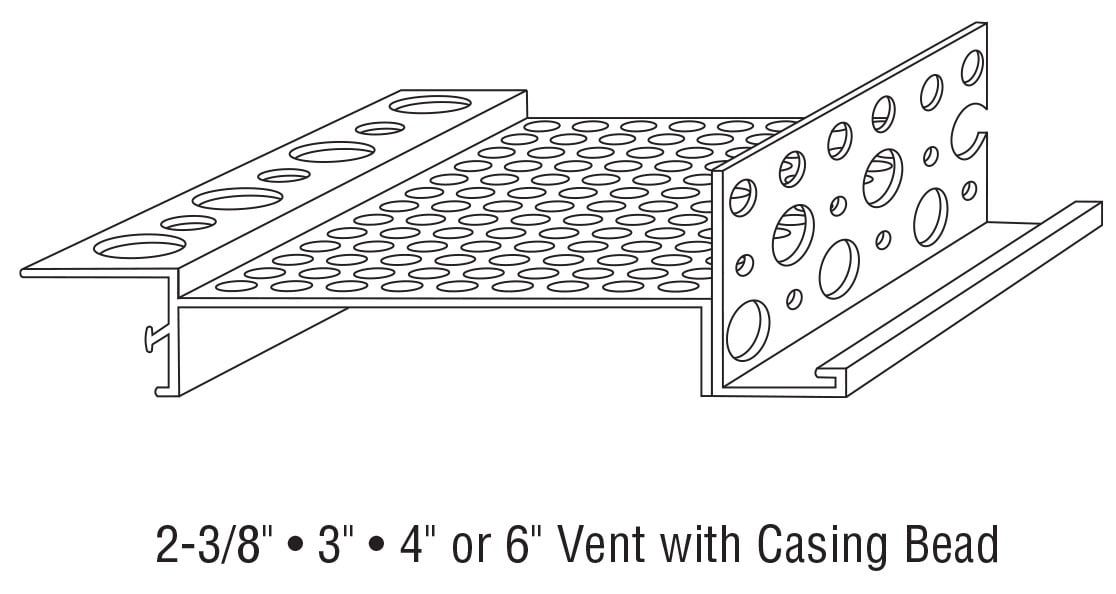

Figure 6

Figure 5

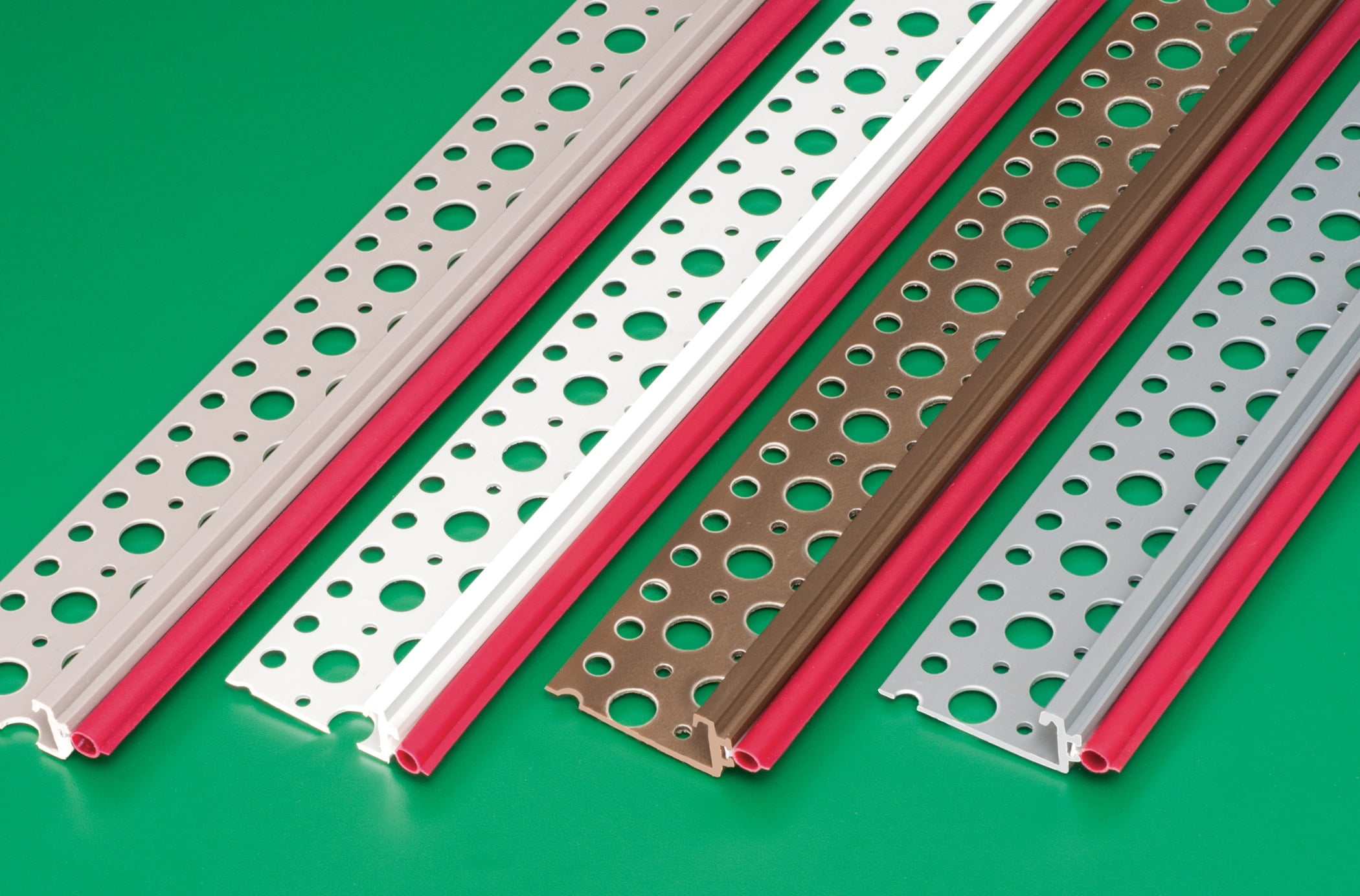

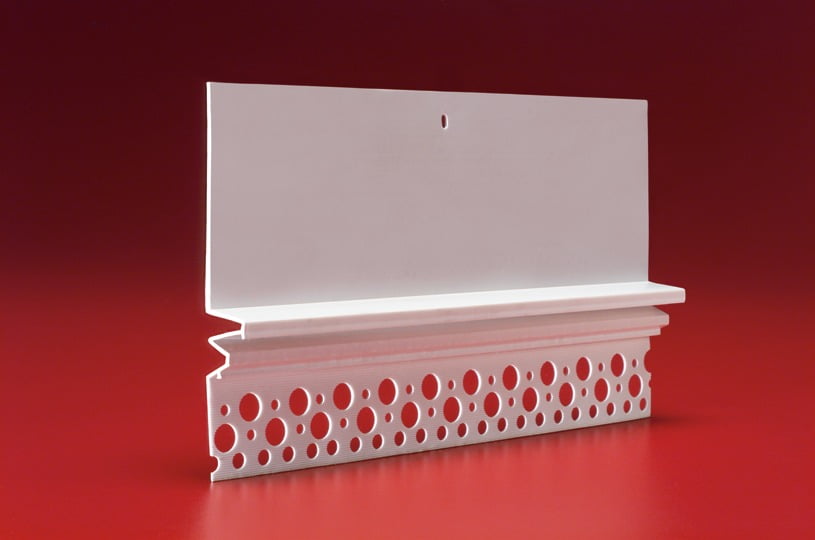

CI Stucco Accessories

Continuously insulated stucco systems incorporate exterior insulation up to approximately 2 inches thick which can result in challenges to detail and encapsulate the system using traditional lath accessories. Specially designed CI stucco accessories such as shown in Figures 5 and 6 are options to consider when terminating and enclosing the system at openings, tops and bottoms of walls, etc.

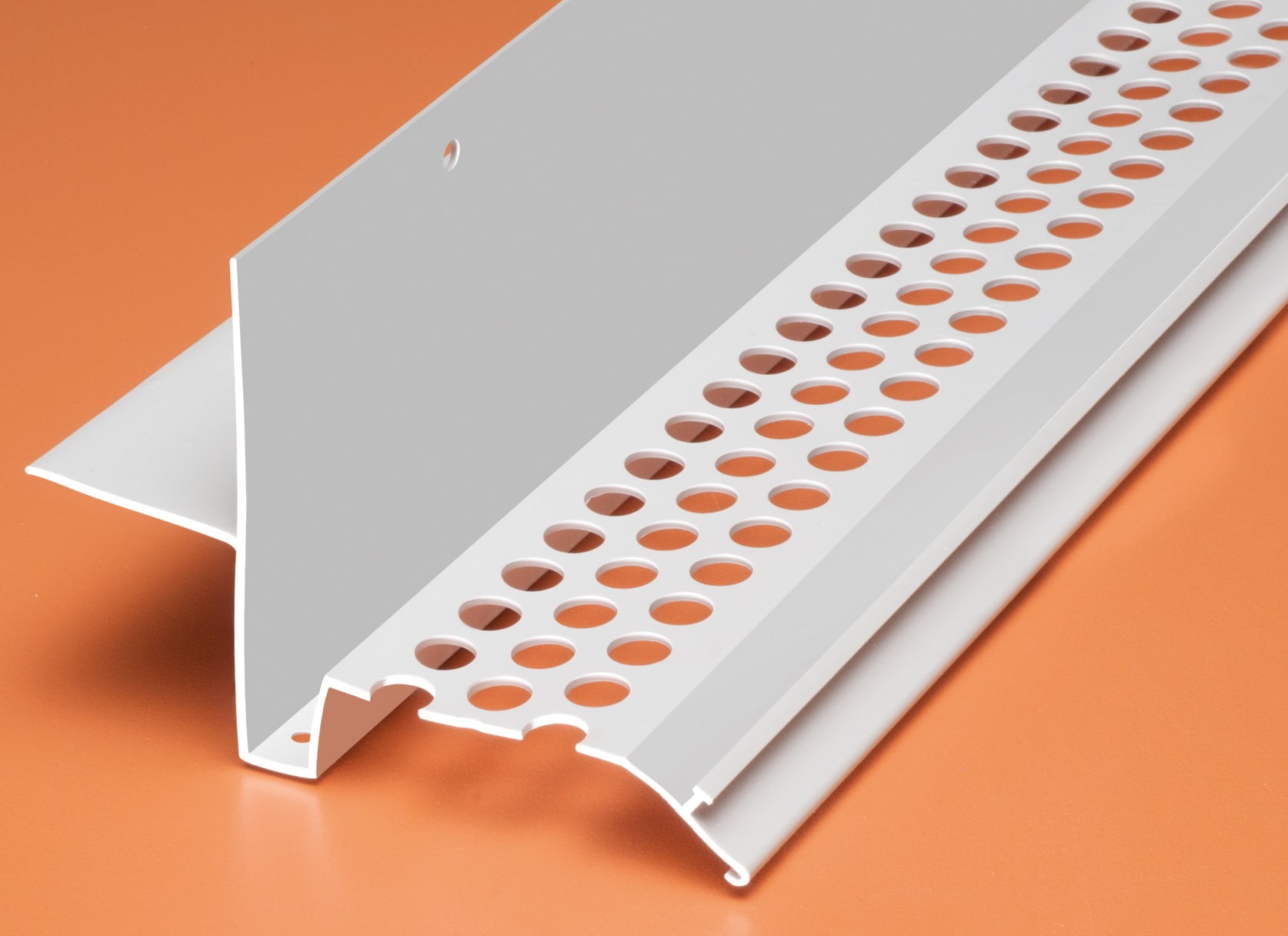

Figure 8

Figure 7

Lap Siding Step Bead

The appearance of conventional lap siding can be attained with stucco through use of a lap siding step accessory. The double ground product shown in Figure 7 functions as a screed to control the different stucco thicknesses at the top and bottom of the accessory which provides the look of lap siding with a stucco system.

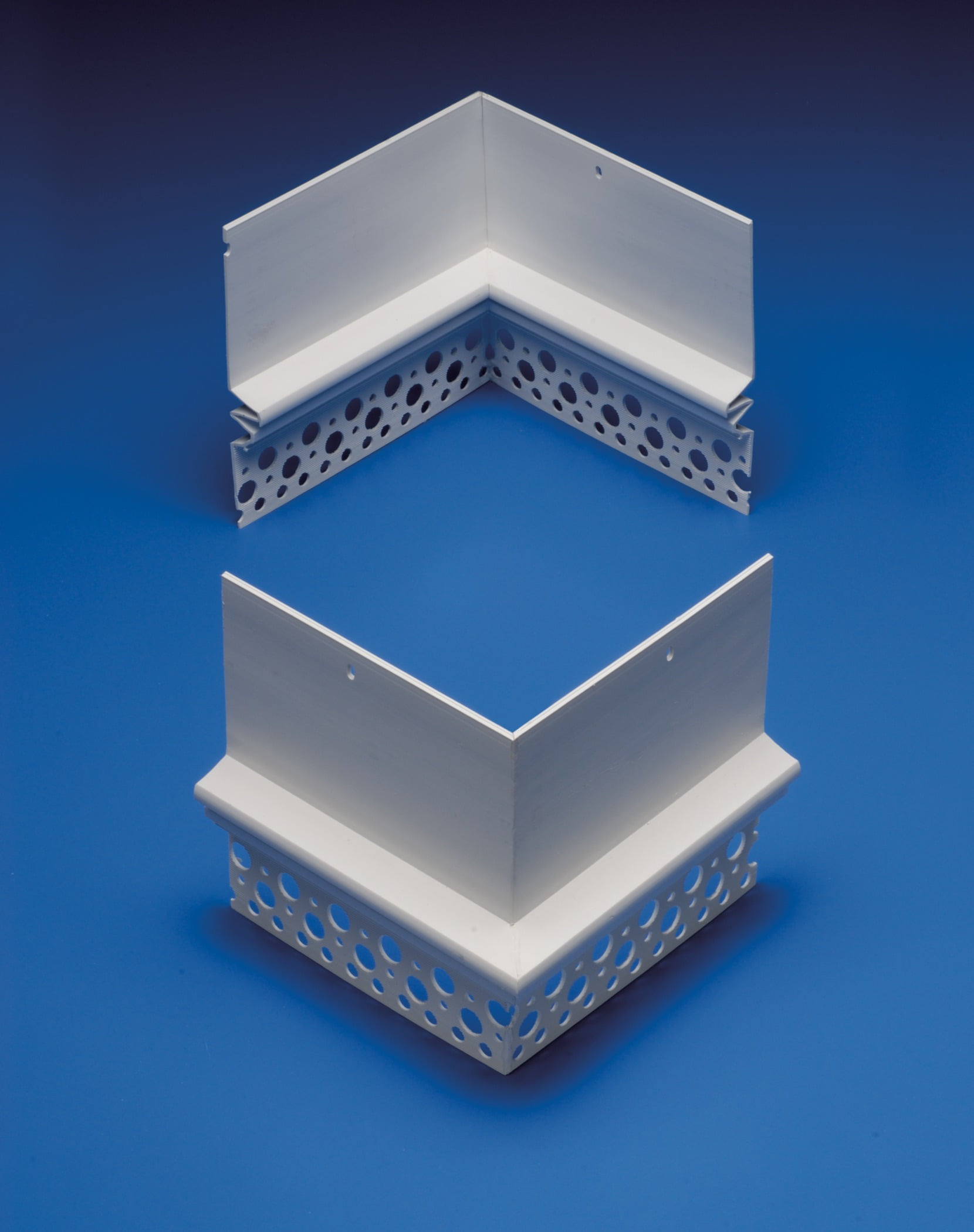

Factory Fabricated Intersections and Corners

Lathing accessories that abut or adjoin at corners and intersections entail time consuming cutting and alignment to achieve proper fit and appearance. Single piece, factory fabricated accessories, such as shown in Figure 8 can reduce labor, complexity, and provide a high-quality finished appearance.

Figure 9

Custom Products

A wide range of standard lath accessory types and profiles are available that suit the needs of most projects and conditions. For unique circumstances or conditions, custom or project specific products, such as shown in Figure 9 are an option.

While traditional, commonly used lath accessories such as casing and corner beads are important, innovative lathing accessories provide additional options to further facilitate lath and stucco installations.

Photos courtesy of Plastic Components

Plastic Components’ Director of Worldwide Sales Herman Guevara has more than 30 years of experience in the building materials industry. He has lived and worked in North and South America, including Argentina, Mexico and Puerto Rico. He holds a BA in business administration from the University of Michigan and a Master’s Degree in International Management from AGSIM (Thunderbird). Guevara is active on many industry boards and committees including AWCI, FWCCA and ASTM.

Bill Egan has more than 35 years of construction experience that includes product and system design, standards development, testing, building code compliance as well as claims and construction defect litigation. He is principal of the Bill Egan Group (billegangroup.com) and is also associated with Intertek Building Science Solutions as a part time Senior Project Consultant. He has held technical roles with manufacturers of EIFS, stucco, air/water resistive barriers and architectural coating systems. Egan graduated from Roger Williams University with a B.S. in Civil Engineering, holds numerous patents, and actively participates in various industry associations. He also serves on ASTM committees related to stucco, lath, air/water resistive barriers and is E 6.58 subcommittee chairman for Performance of EIFS.