Self-leveling Cross Line Lasers

Empire Level

The company introduces two self-leveling lasers: A 75-foot and 125-foot green self-leveling cross line laser. With more range and more run-time, the new lasers provide users with enhanced visibility for all-day use on the jobsite. Equipped with a brighter and more powerful green laser for enhanced visibility, the levels deliver up to 4x the brightness than single diode red lasers. For increased durability, all laser electronics are impact protected with a rugged rubber over-mold and locking pendulum. For easy setup, both Laser Levels feature tripod mounting points and rare earth magnets with best-in-class magnet strength to securely hold to metal surfaces. For more information, visit empirelevel.com.

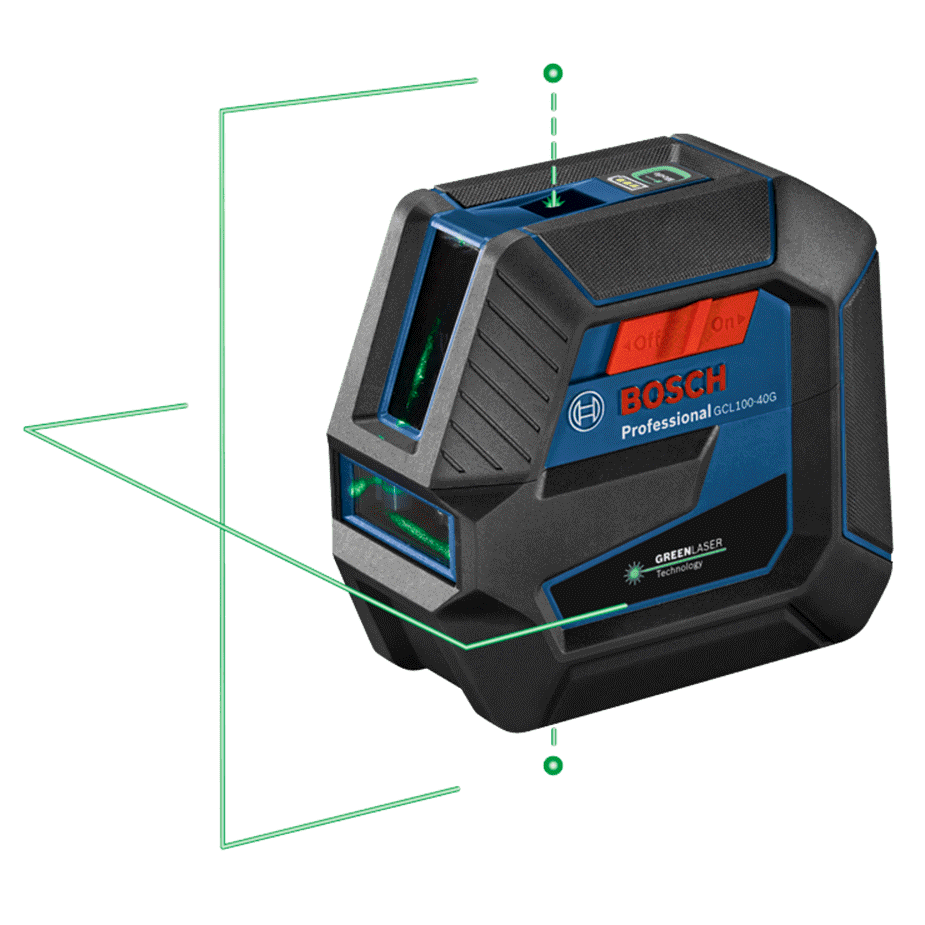

Green Beam Self-leveling Lasers

Bosch

The GLL100-40G Green Beam Self-Leveling Cross-Line Laser and the GCL100-40G Green Beam Self-Leveling Combination Laser with Plumb Points use green-beam technology to emit vibrant green lines and points that are 4X brighter and more visible to the human eye than standard red beams—even in direct sunlight. Featuring the innovative Bosch-exclusive VisiMax technology, which monitors tool temperature and power consumption, the lasers automatically optimize the line visibility and brightness to help prevent the tool from overheating while maximizing the battery life and extending runtime on the project. Like all the company’s tools, the lasers are engineered to be jobsite tough. Deeply recessed laser glass windows and an IP64 rating help ensure the tools are protected from rainy and dusty jobsite conditions. For more information, visit bosch.com.

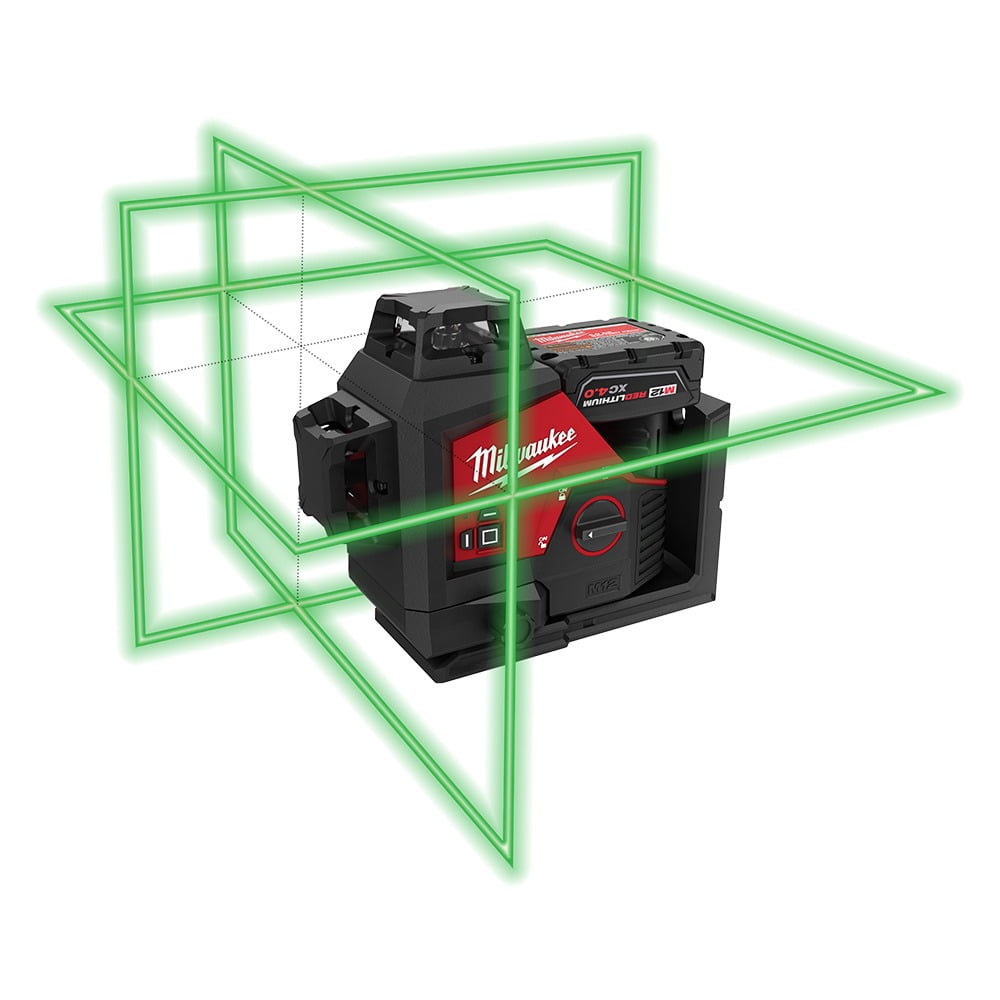

3-Plane Laser

Milwaukee Tool

The M12 System Green 360º 3-Plane Laser provides power, visibility, and easier set-up. The laser provides all-day run-time and best visibility in their class. Utilizing M12 REDLITHIUM Batteries, users can get 15-plus hours of continuous run-time. The brightest green lasers offer users superior visibility up to 125-feet for long-range productivity and, additionally, achieve up to 165’ of range with a laser detector. Setting up lasers for layout or install applications is often tedious or time consuming. For fast, versatile setup, all these lasers feature micro-control adjustments that pivot on point delivering precise control and faster point to point alignment. Amplified rare earth magnets provide a secure hold and ensure the laser won’t slide on steel studs or other metal material, allowing users to setup anywhere. For more information, visit milwaukeetool.com.

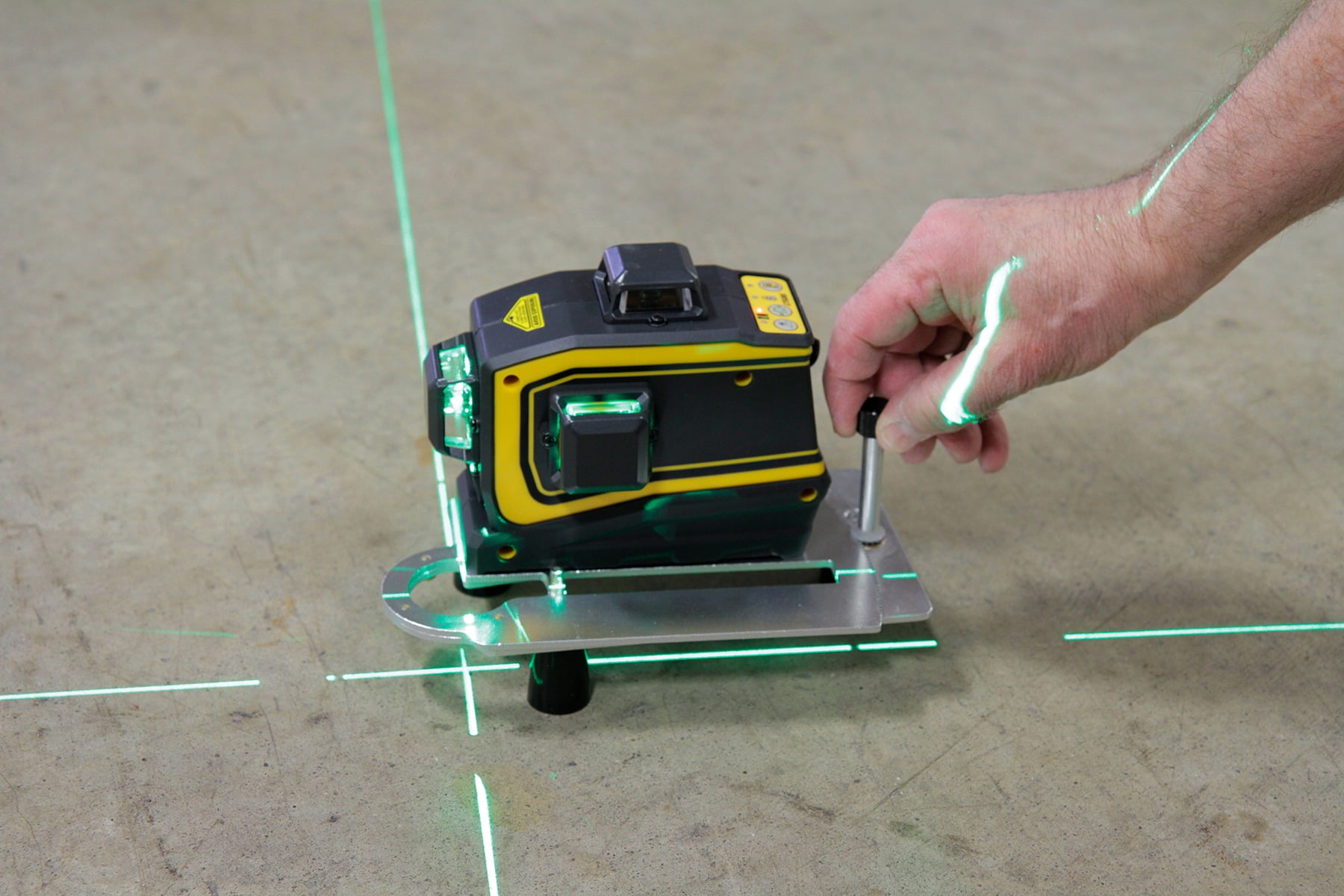

Interior Lasers

Trimble Inc./Spectra Precision Lasers

The LT56 and LT58G interior lasers are red and green beam lasers with 3 x 360° planes of coverage. The horizontal plane is optimal for ceiling work. For alignment, plumb, and square layout, the two vertical planes are spaced 90° apart. Packages are available with the M156 fine adjustment floor trivet. The trivet is ideal for quickly aligning a second point at distance for the layout of walls, lines, 90° layout and other interior alignment tasks. The lasers are shipped with a compact carrying case along with all its standard components, including the adjustable ceiling mount. For more information, visit trimble.com.

Layout Laser

Hilti

The layout tool PMD 200 measuring system can take a layout from a two-worker to a single worker task, helping users complete diverse layout projects, including drywall installation or finding anchor points, in a faster, safer and more efficient way. The innovation is powered by 12V batteries, offering up to hours of cordless operation. It was designed to give customers the accuracy and productivity benefits of a digital solution without the added complexity of having to manage AutoCad data or change existing workflows. The tool can now easily create an arc between two existing points using a given radius or offset. Reflective ceiling plans can quickly and efficiently be done in only 30 minutes. Users are also able to measure any distance between two layout points or reference points, which allows to cross-check and verify layouts done with the tool. For more information, visit hilti.com.