EIFS:

The Durable,

Energy Efficient Cladding Solution

EIFS:

The Durable,

Energy Efficient Cladding Solution

EIFS:

The Durable,

Energy Efficient Cladding Solution

No modern exterior cladding can claim a multitude of benefits perhaps as much as an EIF system. The cladding has now been the proven choice for exterior cladding in North America—as well as other countries—as it relates primarily to aesthetics and energy efficiency. Yet, the benefits aren’t restricted to curb appeal and utility bills. Although created in Europe, the United States was an early adopter of the system and today generates the most in sales worldwide. This Infographic will outline its features and benefits.

- EIFS is a highly energy-efficient system.

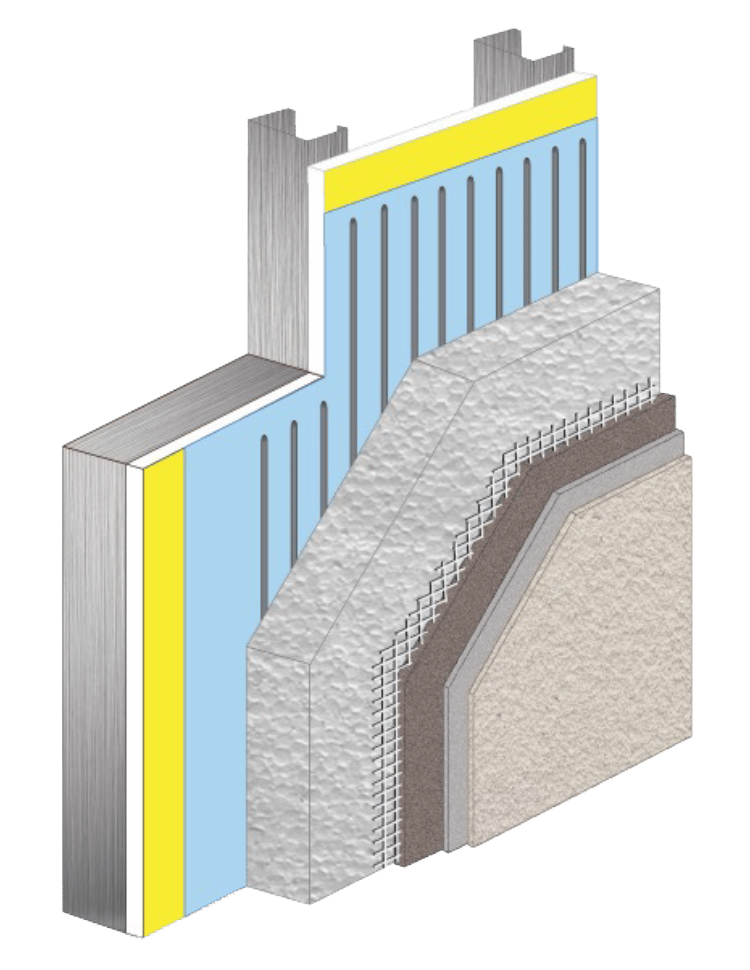

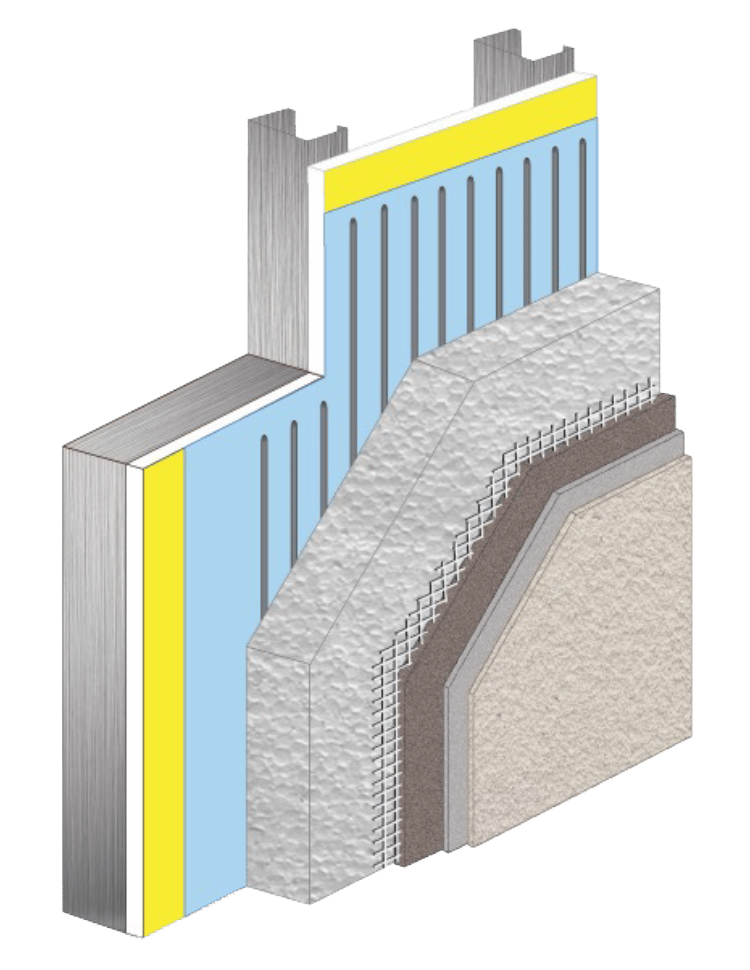

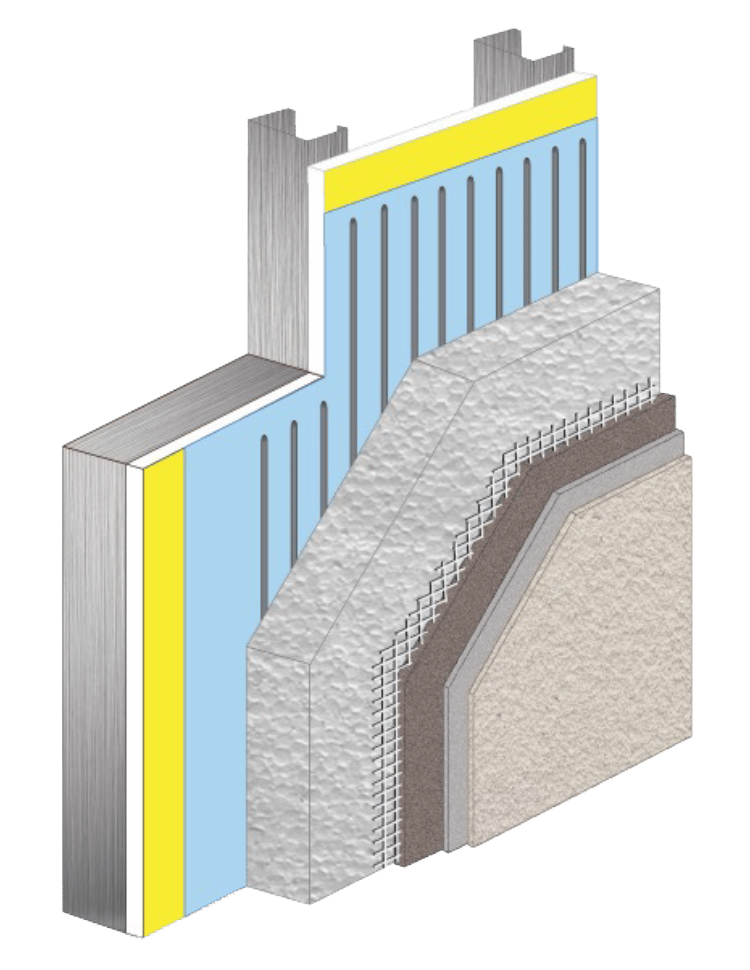

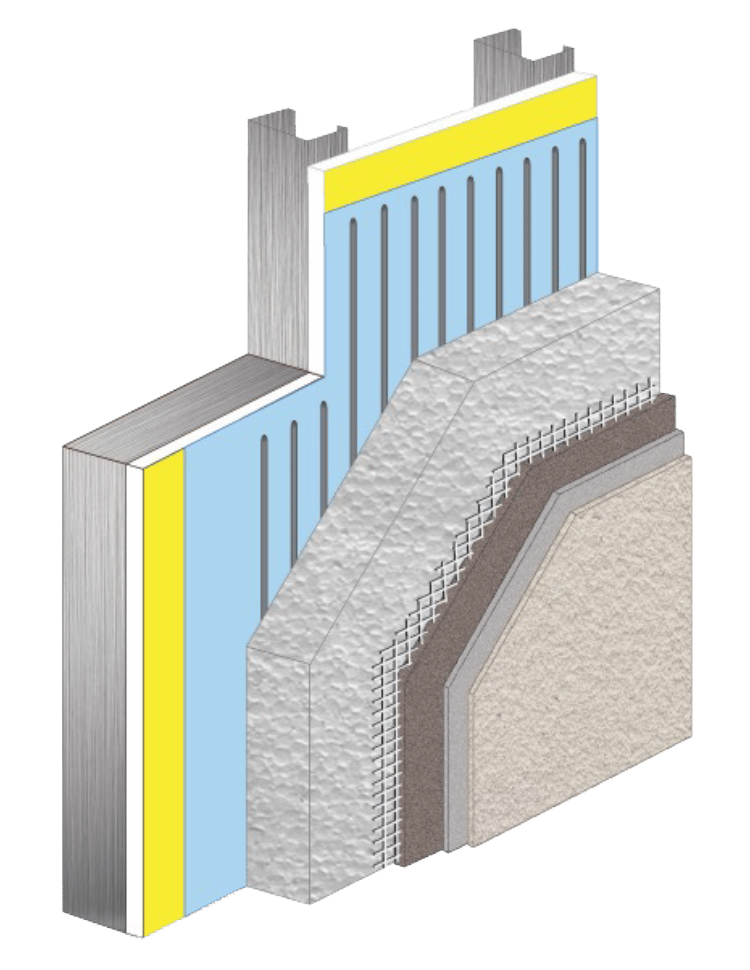

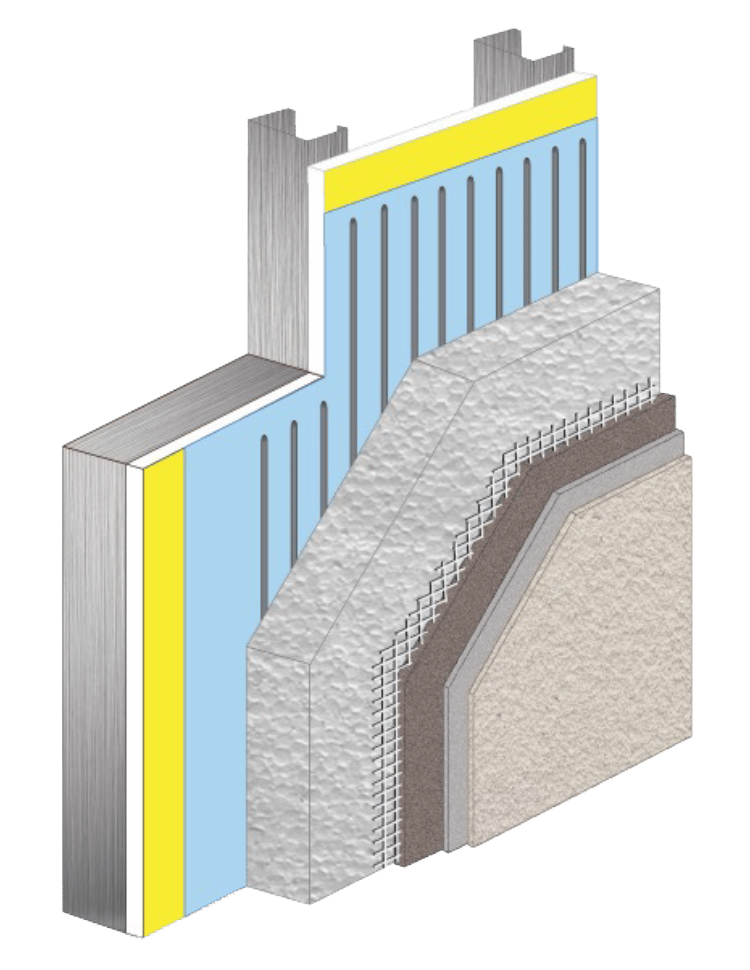

- EIFS typically consists of the following components: A water resistive barrier that covers the substrate; A drainage plane between the WRB and the insulation board that is most commonly achieved with vertical ribbons of adhesive applied over the WRB.

- EIFS is simply an externally located, insulated-wall cladding system. It consists of a foam insulation layer, a reinforced coating system on top of the insulation, and a decorative outermost coating.

- Most EIFS use EPS (expanded polystyrene) insulation. EPS has a maximum sustained working temperature of approximately 165 degrees F.

- EIFS was originally developed as a retrofit cladding material for solid substrates like concrete and masonry. EIFS was intended for use on vertical exterior walls and at times was misused. The rule is to keep EIFS 8 inches above grade.

As builders and project managers understand, there are several factors determining the cost-effectiveness of a project. Codified city laws create a framework for the range of materials builders are allowed to consider.

Choices—including the kind of cladding, HVAC, windows, and other components in a building—impact both the costs of construction and operation, as well as the efficiency of the structure.

EIFS is a “Goldilocks” material for cost savings. They are far less expensive to install, transport, and maintain consistent building temperatures relative to traditional materials. Public and private sector building managers save costs in implementation, while tenants save in utility costs. Lower construction operating costs translate to savings for taxpayers when projects such as affordable housing developments and schools incorporate EIFS.

- Saves homeowners up to 50 percent on heating and cooling costs with proper insulation and air-sealing, according to the U.S. Department of Energy and the U.S. Environmental Protection Agency.

- Achieves 50 percent energy savings in commercial construction when energy-efficient design elements, such as rigid insulation board (included in all EIFS wall cladding) are used instead of typical materials and methods, as referenced by DOE.

- Eliminates thermal bridging heat loss with continuous insulation (another key component in all EIFS), which saves 20-70 percent of heat flow through building walls over and above an equivalent R-value of cavity insulation, according to ASHRAE Research Project Report RP-1365.

To provide third-party credibility and empirical insight, EIMA—the trade association that represents the EIFS industry—used RSMeans, a firm that has been around since the 1940s, to secure accurate and up-to-date construction estimating cost data for individual building components and the building as a whole – including labor costs, overhead and profit. RSMeans is a reputable source and engineers, architects, and informed planning officials are familiar with this data. This data was pulled in September 2023:

0

%

Other cladding materials, such as fiber cement, have a lower R-value, which means that they need an insulation material added in if they want to attain a meaningful R-value at all. Consequently, it is no surprise that EIFS was the first Continuous Insulation system to meet the DOE’s 2013 mandate that all states update their commercial building codes to meet or exceed ASHRAE Standard 90.1.

EIFS: 4.00 - 5.60 (varies depending on insulation material).*

Poured Concrete: 0.08

Glass: 0.14

Wood - 1.25

Stucco: 0.20

Stone: 0.08

Brick: 0.20

One of the primary reasons why EIFS is such a superior performer is due to the modern, engineered insulation system used in EIFS is much more robust than old-line building materials. Consider the R-value of several, frequently used cladding materials. R-values measure how much resistance the insulation has to the flow of heat. This means a higher R-value has better insulating effectiveness. Below is a comparison of commonly used building materials on a per-inch basis:

Material R-value Per Inch

Features & Benefits

- EIFS was developed in Europe after WWII as an economical stucco-like cladding that added insulation qualities and was easier to install than stucco over masonry walls. EIFS has been in use since the 1960s in North America.

- Since the 1990s, a number of wood-framed buildings have used EIFS.

- Its emergence into the American market is typically attributed to Frank Marsilli, who launched Dryvit in the United States after he was introduced to the system in Europe in the 1960s.

- What makes EIFS attractive to both builders of commercial properties and residential homeowners is namely two-fold: its exterior aesthetic appeal as well as its insulative properties.

- In the end, remember that EIFS is not stucco. With the density of real stucco, you can secure some objects against the stucco membrane. This is because when properly done, cement membrane will not collapse when tightened down. EIFS is a lightweight, thin, flexible material, and simply does not lend itself to having items applying pressure to the surface. Thus, the key to attaching heavier items to EIFS is to use dense spacers, blocking or other means that will not compress the EPS. Whether stucco or EIFS, all but very light items should be attached to framing, masonry or concrete.

- A myriad of types of EIFS exist around the world, yet two basic EPS-based types are popular in North America: barrier and drainage types. European EIFS producers find our drainage EIFS to be a bit odd. They don’t understand why we need drainage. This is because unlike the U.S., EIFS in Europe is not often used on framed walls. Even in North America, we prefer barrier EIFS when over concrete or masonry. IBC and IRC mandate drainage for EIFS over framed walls.

- Cement stucco at 7/8 inch is a fire-rated membrane. EIFS gets its fire rating from the gypsum sheathing under the EIFS.

- EIFS has benefited the stucco industry. Decorative foam shapes and the crack suppression membrane common with stucco today is thanks to the EIFS market. This also includes the Direct Applied System (DAS) used on ceilings in lieu of heavy cement stucco.

- EIFS are proprietary systems and must adhere to those manufacturers’ requirements.

- EIFS are significantly less expensive to install than other comparable materials in large-scale installations. The affordability of EIFS means public schools, public housing developments, and other government buildings pay far less in material and transportation costs when they implement EIFS in construction which, in turn, saves public money.

Future Market Insights has released its market report for the EIFS industry. The report includes predictions, trends and information about the EIFS market through 2033.

According to the report, the EIFS market is expected to grow over the next decade due to an increase in construction and infrastructure spending as well as energy efficiency methods.

Future Market Insights conducted a market survey report that showed that EIFS’ aggregate demand in 2022 was $79.8 billion. FMI expects that number to rise to $235.6 billion in 2033 with a Compound Annual Growth Rate of 10.2 percent.

$79.8

BILLION

Future Market Insights has released its market report for the EIFS industry. The report includes predictions, trends and information about the EIFS market through 2033.

According to the report, the EIFS market is expected to grow over the next decade due to an increase in construction and infrastructure spending as well as energy efficiency methods.

Future Market Insights conducted a market survey report that showed that EIFS’ aggregate demand in 2022 was $79.8 billion. FMI expects that number to rise to $235.6 billion in 2033 with a Compound Annual Growth Rate of 10.2 percent.

$79.8

BILLION

- EIFS demand is expected to increase in the United States: U.S. demand for EIFS is anticipated to have substantial growth. A CAGR of 10.2 percent is predicted to cause the growth.

- The United Kingdom market has a positive outlook: The EIFS market in the U.K. is projected to grow to a $9.2 billion net worth by 2033. A 10.1 percent CAGR is expected to occur over that timeframe.

- The Asian markets have growth prospects: The EIFS markets in China, Japan and South Korea are anticipated to have significant development, with an average CAGR of 10.1 percent through 2033. The most robust EIFS market in the Asia Pacific region is China’s, which is predicted to reach $53.6 billion by 2033. Meanwhile, the markets in Japan and South Korea are projected to reach $45.2 billion and $15.8 billion, respectively, by the same year.

- Polymer-based EIFS products: The polymer-based EIFS product segment is anticipated to grow at a 10 percent CAGR over the next decade.

- Polymer-modified EIFS products: In contrast, the polymer-modified EIFS product segment is expected to have significant expansion by 2033.

What the Future Holds for EIFS

Almost all respondents indicated an increase in material pricing over the past 12 months.

Product Sales

On average, drywall accounts for over one-quarter of product sales, while insulation and ceilings combined account for another one-quarter of sales. Insulation and ceilings are tied in second place, with steel framing a solid fourth.