To Leak or

Not to Leak?

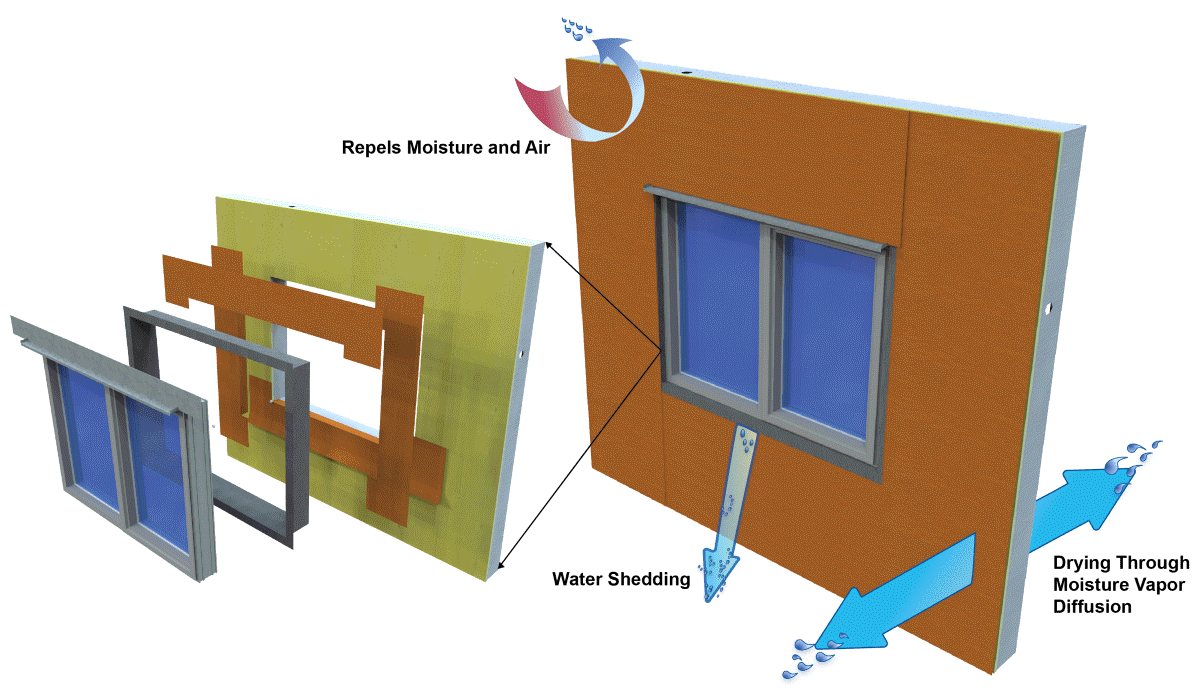

Vapor permeable membranes reduce risk of moisture accumulation related to air leakage.

By Scott D. Wood

Due to the in person restrictions imposed from the COVID-19 pandemic, communications have gone a virtual route. As a building scientist, I engage in multiple discussions with design professionals, general contractors and installing contractors online. A large percentage of these conversations revolve around rough opening sequences, materials, best practices and installation guidelines.

To begin we must define the term “rough opening.” A rough opening is a penetration in the building enclosure fitted with fenestrations that leak, or will leak at some point of the service life of the building. Fenestrations are commonly referred to as doors and windows. It is critical to properly direct those leaks out of the enclosure.

Figure 1: Flashed rough openings awaiting window installation.

Figure 1: Flashed rough openings awaiting window installation.

The next step would be to review the materials specified for the rough opening details. Materials may include tapes, sealants and flashing products. These components should be water and air tight. They can be either vapor tight or vapor open. The manufacturer’s product data sheets for the specified materials should be referenced for water, air and water vapor transmittance properties. UV exposure limits should be confirmed, especially when an open joint cladding assembly is used. When the system is installed correctly, these materials should prevent water from entering into the interstitial wall cavities. This type of rough opening assembly allows the “leaks” to drain out of the building enclosure.

After confirming the materials meet specifications and are compatible, understanding the details and sequencing is the next aspect of the process. Flashing components previously noted above can fail over time. Failures can occur due to improper installation, incompatible materials, or damage from other trades. This can lead to leaking of heat, air and moisture. Evidence of this will show in the form of condensation issues, mold, and even rot or rust of the framing components. How can this be avoided?

Figure 2: Poorly flashed rough opening showing substrate degradation due to water intrusion.

Designing the RO to Succeed

What is the perfect rough opening? In my experience as a building scientist, the design should include the following elements. They should be plumb with a sloped sill, including a back dam (back angle), properly sized RO and correctly flashed before the fenestration installation.

Typically, the opening is larger than the fenestration to accommodate shimming, backing rod and sealant joints. After the fenestration is installed, a head flashing component is integrated with the field WRB/AB membrane shingle lapped during the process. To maintain air barrier continuity, an interior air barrier seal should be installed between the flashing system and the window.

It should be noted the building enclosure must be designed to limit heat flow, air flow and moisture flow. The building should be enveloped with materials and systems that restrict heat flow, air flow, bulk or liquid moisture and moisture vapor or HAM. Moisture causes the most damage to a building. It is vital that moisture is kept from entering the rough opening.

Figure 4: Typical commercial mockup.

Figure 3: Rough opening system using vapor permeable materials allowing draining and drying.

We review the design, installation and sequencing using a mockup. Testing for HAM (Heat, Air and Moisture) can be performed on the mockup. Mockups are a guide and a physical representation showing sequencing and integration of various elements of the assembly. So why do such a high percentage of commercial construction projects fail to utilize a mockup?

Vapor tight vs. Vapor open

Construction projects which utilize a vapor impermeable wall assembly do not allow moisture to escape via vapor diffusion. This science applies to both wood framed and cold-formed steel wall assemblies. Recent research and construction defects have shown that moisture can be trapped by vapor impermeable systems. Vapor impermeable assemblies are less tolerant of water intrusion.

Figures 5 & 6: Condensation on a vapor barrier eventually leading to damaged drywall.

Referencing a third party report of hygrothermal analysis of permeable membranes shows vapor permeable assemblies are more tolerant of rain leaks¹. This study showed vapor permeable membranes reduce risk of moisture accumulation related to air leakage. It also increased drying of wood structures. Highly vapor permeable sub sill membranes are more effective where rain coincides with cold weather.

As an independent consultant/instructor and senior building scientist for a WRB/AB manufacturer, building science has proved the importance of vapor permeable systems in all types of construction projects. The current “Perfect Wall/RO” employs a vapor permeable assembly. By utilizing vapor open systems for the rough opening, water can escape via vapor diffusion. By using mockups, vapor permeable systems and proper installation techniques, the RO has the best chance to succeed. Are your current projects utilizing these materials and techniques? If not, how long until they look like this?

Figure 7: Exterior cladding and substrate removed showing internal damage due to improperly flashed RO.

Figure 8: Representation of permeable rough opening assembly

[1] Morrison Hershfield Hygrothermal Analysis of VaproShield Vapor Permeable Membranes September 23, 2016

Opening Video and Image Credit: G-o-o-d-M-a-n / Creatas Video+ / Getty Images Plus and sl-f/ iStock / Getty Images Plus via Getty Images.

Remaining images courtesy of VaproShield.

Scott D. Wood is the senior building scientist at VaproShield, providing product QA/QC and investigations/testing of material properties. As a building scientist he provides technical support for the company’s representatives, clients and assists in the development of product literature and presentations. Wood is also president of SWA Consulting. As an ITC certified Level III Thermographer with decades of experience he has many publications in areas of both thermography and building science. He provides investigations, consulting, presentations and training in Building Science Thermography.