Rainscreen

Product Focus on

Product Focus on

— Framing Solutions—

Drywall Grid

Armstrong World Ind.

The FrameAll Drywall Grid now has knurled ridges along the length of the cross tee. The new feature improves screw grab and reduces screw spin-out during board installation. In addition to improving handling, the knurled ridges also stiffen the tees. When screwing tee to tee, there is no need to C-clamp the tees together for a quick, clean screw grab through both tees. Knurled ridges are one of several standard features that provide a performance advantage enabling installers to work faster and easier. FrameAll products carry a “Made in the USA” label, indicating the material is sourced and manufactured in the country. For more information, visit armstrongceilings.com.

Framing Tool

FastenMaster

The newest cordless FrameFAST Structural Framing System is designed to drive jobsite productivity. The cordless tool offers contractors and installers a tangle-free experience that increases safety on the job site while increasing speed and productivity. With the choice of a professional grade drill, the tool comes with a limited three-year warranty. Using the recommended battery, users will be able to drive up to 200 fasteners on a single charge. The system consists of both the structural wood screw and the tool. One tool, with three interchangeable heads, provides consistently accurate installation along with increased speed and safety, and eliminates a variety of clips, straps and ties used to transfer forces from one faming member to the next. Critical connections are made five times faster and provide greater uplift and lateral load capacity. For additional information, visit fastenmaster.com.

Online Available Parts

Radius Track

The company now fabricates curved metal parts to the contractor’s specifications with the company's online ordering system. So, whether one needs curved material today or looking for pricing, these parts are ready to install immediately in 10-foot lengths. Each component is precisely manufactured with 1/8 inch tolerance for a consistency that makes finishing simple. Benefits include:

- Standard curves for most profiles: bend, crimp and roll;

- Available in track, slotted track, studs, angle and furring channel;

- Gauge availability: 20, 18, 16 and 14;

- Finish coatings include G60 and G90.

For more information, visit parts.radiustrack.com.

Collated Fastener for Steel Framing

Grabber Construction Products

The SuperDrive Mach1 is a collated system explicitly designed to meet the demands of onsite and offsite light-gauge steel frame construction, offering unparalleled speed, precision and efficiency. It is a strong solution for metal framing professionals looking to enhance productivity, improve installer safety, reduce material waste and improve fastener precision. The collated system easily attaches to impact drivers. The tool’s advanced features also include a no-slip tip, reversible feed track (for right- or left-handed workers), SureLock fine depth adjustment, quick removal strap, as well as a compact and durable design that includes pass-through spaces for the impact driver’s LED lights. The new tool is compatible with SuperDrive 7/16- to 7/8-inch collated screws. Learn more at grabberpro.com/mach1.

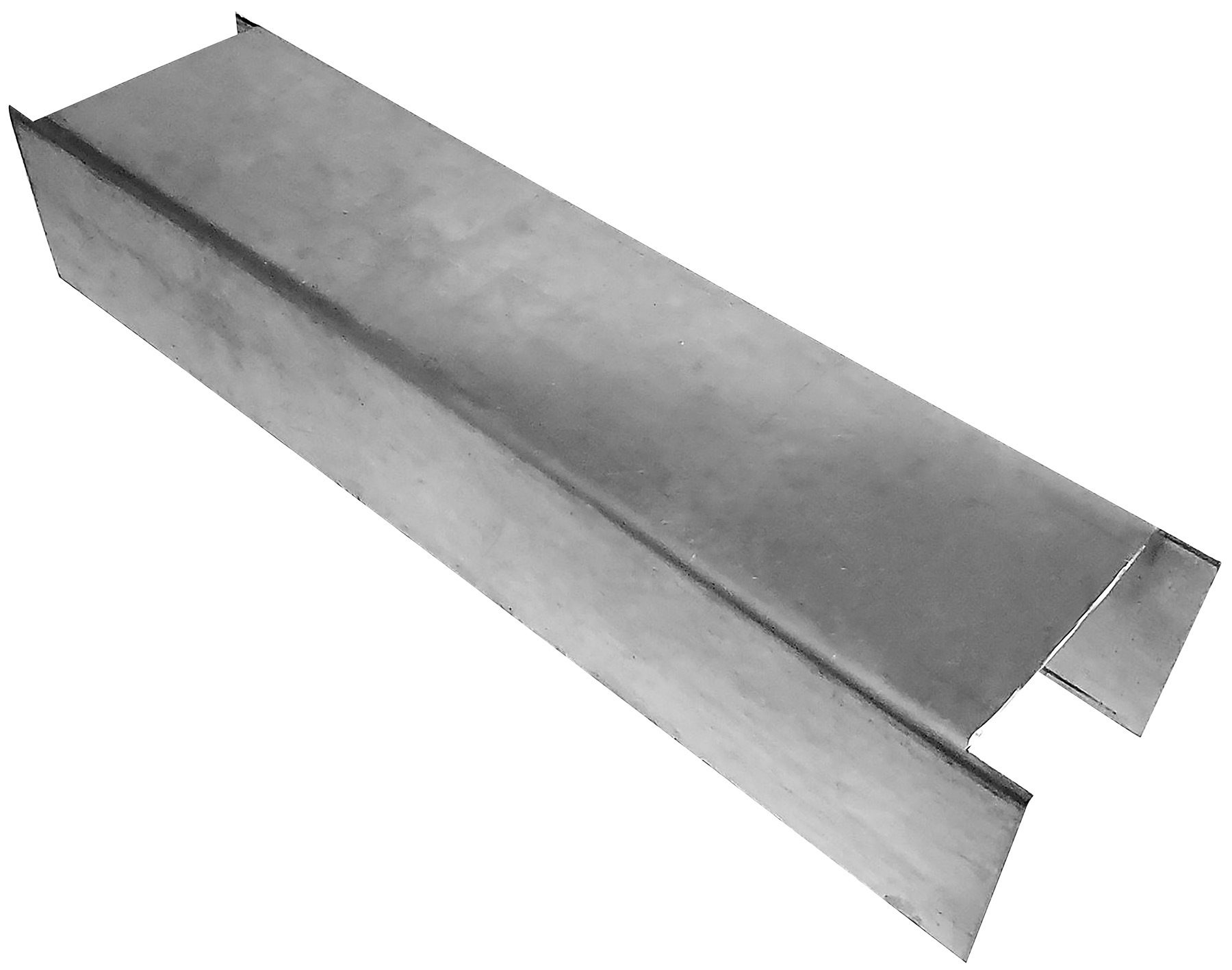

Heady-duty Wall Blocking

Telling Ind.

Blocking a wall refers to installing a short reinforcing piece of metal framing horizontally between the vertical studs. The purpose of blocking is to provide an attachment support point for mounted construction features like handrails, shelving, frames, cabinets, railings or other fixed hardware. T-Block offers heavy duty blocking that significantly increases the anchor strength and stability of permanent mounted wall fixtures. Available in 16 and 20 gauge (30 mil) with standard G60 coating. Accommodates 12-, 16- and 24-inch on-center stud spacing. It Fits 3 5/8-, 4-, 6-, 8-, 10- and 12-inch web sizes. For more information, visit buildstrong.com.

Drywall Framing System

ClarkDietrich

The TRAKLOC Drywall Framing System is a development in cold-formed steel framing systems. Unlike traditional steel studs, which are cut to length for varying jobsite conditions, the system allows you to order one length member and “adjust” the length accordingly to make up for variances in the slab. The stud-and-track systems consist of a traditional-style framing member, combined with an interlocking adjustable component. The adjustable portion allows for telescopic length adjustments and can accommodate variances in the slab, minor wall heights per floor, etc. The interlocking component of the stud and track eliminate the need for most connections. For more information, visit clarkdietrich.com.