Trade News

ClarkDietrich’s Steel Framing named Sustainable Product of the Year

Underscoring its commitment to becoming the greenest manufacturer of cold-formed steel framing, ClarkDietrich’s low embodied carbon steel framing products have been awarded as a 2025 Sustainable Product of Year by Green Builder Media.

“We are honored to receive this recognition from the Green Builder team, which further validates ClarkDietrich as a sustainable leader in the industry,” said Adam Shoemaker, director of corporate sustainability for ClarkDietrich. “This is another milestone on our continued commitment to sustainability, as we strive to reduce impact and enhance transparency in the manufacturing of our steel framing products and drive progress across the industry.”

ClarkDietrich launched its low embodied carbon products in 2024, becoming the first steel framing manufacturer to offer LEC solutions nationwide. The company’s LEC products—which include ProSTUD drywall framing system, structural studs, clips and connectors, floor framing, and more—have been proven to contain up to 30 percent less embodied carbon than their standard counterparts. The products are certified by a third-party EPD that covers LEC CFS products as defined by the United States General Services Administration’s Interim IRA Low Embodied Carbon Material Requirements and qualifies for the top 20 percent limit for cold-formed and galvanized steel products. These products are also ideal for private sector LEED v4.1 projects looking to achieve an Embodied Carbon optimization point.

“The Sustainable Product of the Year selections represent today’s most innovative products that make homes more efficient, resilient, healthy, intelligent, and safe,” said Craig Coale, publisher of Green Builder Media. “In a market where sustainability isn’t just a trend—it’s a buying decision—this recognition gives ClarkDietrich a serious edge and … offers third-party validation of its leadership in the space.”

To learn more about ClarkDietrich’s sustainability commitments, visit clarkdietrich.com/sustainability.

US MgO Sets Up in North Carolina

US MgO announced the purchase of 23 acres of land in Leland, N.C., where it will soon break ground on its second manufacturing plant for magnesium oxide cement sheathing panels.

This new facility will complement the company's first plant currently under construction in nearby Wilmington, making it the only company with two dedicated U.S. manufacturing facilities for MgO panels used in wall and floor applications.

Both plants feature custom-built, proprietary equipment and processes designed to produce our innovative magnesium oxide sheathing panels that directly compete with traditional gypsum and cement panels in building construction.

EIMA Announces EIFS Excellence Award Winners

The EIFS Industry Members Association recognized the recipients of the 2024 EIFS Excellence Awards on March 19th at the EIMA Annual Meeting in Orlando, Fla. In its seventh year, the EIFS Architectural Awards program remains the foremost competition dedicated exclusively to the EIFS industry. After careful deliberation, 22 projects were selected for their exceptional use of exterior insulation and finish systems in architecture, design, and construction.

This year's esteemed jury comprised leading architects, building science experts, and construction industry professionals who evaluated projects based on design excellence, energy efficiency, and creative use of EIFS. The judges were Kirk Rose, (HMC Architects), Joseph Del Ciotto (Lantz Boggio), Peter Freeman (Freeman Kennett), John Edgar (John R.S Edgar Consulting), and David Johnston (former EIMA CEO/Executive Director).

The panel marveled not only at EIFS's architectural adaptability but also the innovative integration of modern EIFS technology, including advanced wall systems with built-in drainage and air and water-resistive barriers, providing superior moisture management and durability.

The winning projects excelled in aesthetics, sustainability, and efficiency. From innovative commercial buildings to multi-family housing, each highlighted EIFS's role in energy-efficient, visually striking designs. Judges praised the adaptability of EIFS across climates and project types, noting its environmental benefits and performance advantages. Chosen increasingly over traditional materials for cost-effectiveness and speed of construction, many winners used EIFS to meet tight schedules while exceeding energy standards amid evolving building codes.

Among this year’s winners, the prestigious EIFS Project of the Year was awarded to The Atrium at Sumner. This exceptional project exemplifies the benefits of EIFS in multifamily housing by combining energy efficiency, affordability, and aesthetic appeal. The Atrium at Sumner utilizes an advanced EIFS system that significantly reduces heating and cooling costs, contributing to long-term affordability for residents. The project's thoughtful design and durable building envelope demonstrate how EIFS technology supports high-quality, cost-effective housing solutions while maintaining architectural elegance.

“The 2024 EIFS Excellence Awards winners exemplify the best of what modern building envelopes can achieve,” the jury remarked. “These projects push the boundaries of architectural creativity while leveraging EIFS technology for superior insulation, moisture protection, and long-term durability.”

The awards ceremony took place on March 19 during the 2025 EIMA Annual Meeting in Orlando.

For a complete list of winners, visit here.

ACI and PCI Release Joint Structural Precast Code

The American Concrete Institute, in collaboration with the Precast/Prestressed Concrete Institute, announced the release of ACI/PCI CODE-319-25, Structural Precast Concrete—Code Requirements and Commentary in PDF format. This highly anticipated code provides essential guidance for the materials, design, and detailing of structural precast concrete buildings and nonbuilding structures.

Developed through a rigorous consensus process, ACI/PCI CODE-319-25 sets minimum requirements for plant-produced and site-produced structural precast concrete incorporating nonprestressed or pretensioned reinforcement. The Design Standard Committee of PCI played a vital role in shaping the code’s provisions and commentary, contributing their extensive expertise to advance the industry.

ACI 319 PLUS subscribers have had exclusive digital access to ACI/PCI CODE-319-25 through the ACI PLUS Platform, featuring robust digital notetaking, enhanced search capabilities, 3D graphics, and comprehensive cross-referencing tools. With this release, the PDF version is now available for wider accessibility, ahead of the physical print edition.

ACI recently expanded its ACI PLUS Platform to provide industry professionals with interactive digital access to multiple new concrete codes and resources. In addition to ACI 319 PLUS, the platform’s subscriptions include ACI 318 PLUS, ACI 320 PLUS, and the ACI 562 PLUS Repair Subscription, offering subscribers seamless access to up-to-date codes, design examples, and supplementary materials.

“The collaboration between ACI and PCI to produce ACI/PCI CODE 319-25 has been phenomenal,” said Andrea Schokker, ACI/PCI Committee 319 Chair. “We owe its success to the dedication and expertise of committee members and staff in both organizations, and we look forward to continuing this strong partnership in the next cycle.”

JLG Whitepaper Unveils Vision for the Future of Job Sites

Aerial lift equipment manufacturer JLG Industries introduces an approach to job site management, moving beyond traditional equipment operation to create interconnected, intelligent work environments in its latest whitepaper: “The Job Site of the Future—From Equipment-Centric to Ecosystem Orchestration.”

“For decades, job sites have relied on access equipment, such as mobile elevating work platforms and telehandlers, to complete tasks at height,” said Nate Hoover, JLG’s senior director of product management. “In JLG’s vision for the future, these machines do more, part of an interconnected ecosystem that communicates, coordinates and optimizes operations in real-time—enhancing efficiency, reducing downtime and improving safety.”

The whitepaper outlines a transformative shift in job site operations, offering an innovative blueprint for leveraging automation, connectivity and data to redefine productivity and safety. Key highlights include:

- Dynamic monitoring and modification of equipment performance

- Real-time data sharing and automated workflows

- Seamless coordination of digital platforms, automated systems and workers

“The job site of the future is no longer a distant concept—it’s emerging today,” said Hoover. “Our vision is that smarter, more responsive work environments can minimize risks and maximize human potential.”

The whitepaper is now available for free download on #DirectAccess. Construction industry professionals, equipment managers and job site front-line workers are invited to explore this transformative vision.

For more information, visit JLG.com.

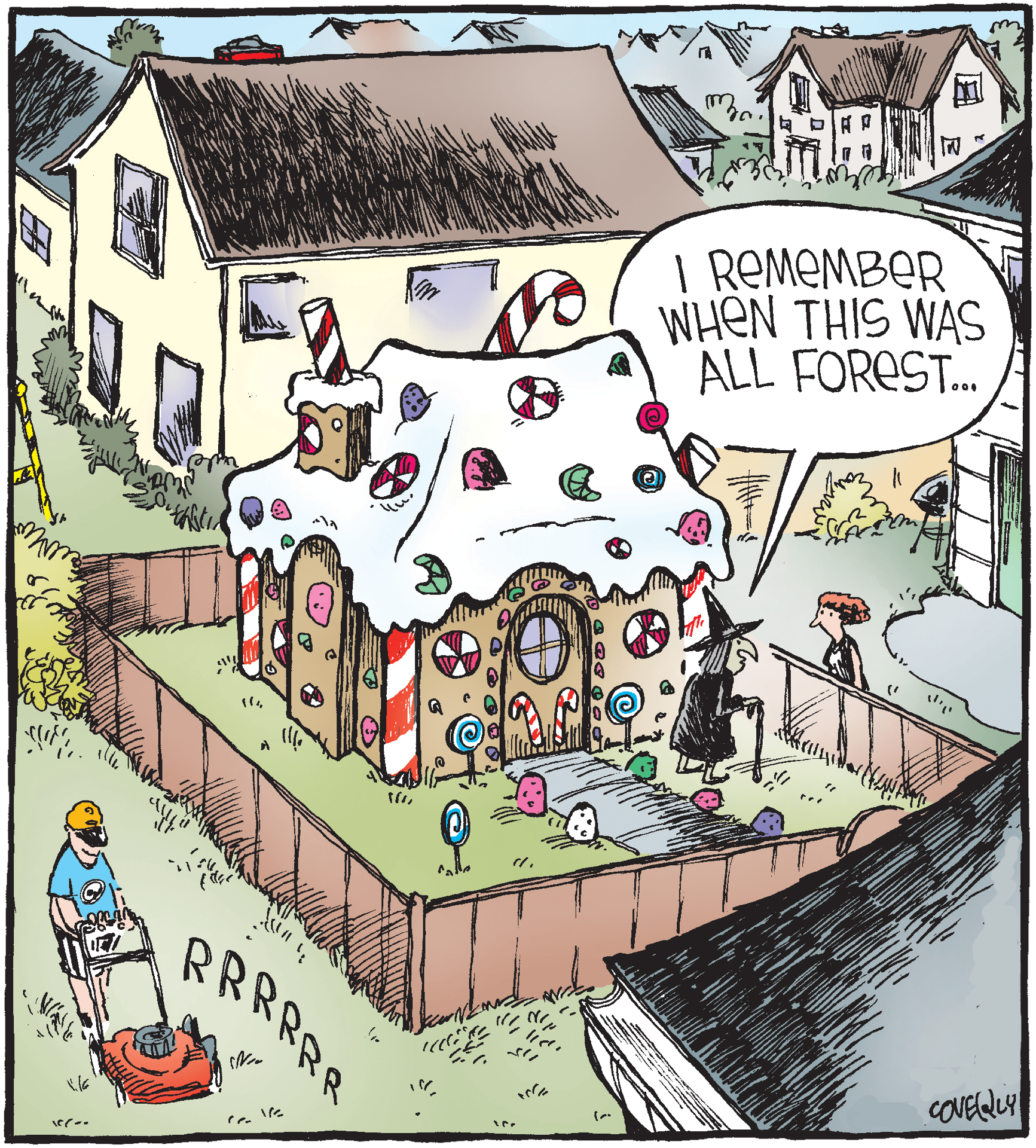

Spackle by Dave Coverly

People News

Brian Panuccio has assumed the role of president and CEO of ClarkDietrich.

Georgia-Pacific announced Julie Howard has been named president of Georgia-Pacific’s Gypsum business.