Trade News

Limited Warranty Now Standard on RectorSeal Products

RectorSeal now offers a three-year limited warranty across an extensive product line that supports the HVAC, plumbing, electrical, and firestop trades. The limited warranty represents the minimum coverage offered by RectorSeal.

“Our company is well known for offering innovative products, so it was natural to apply that thinking to our limited warranty coverage,” said Jeff Underwood, senior vice president of Sales and Marketing at Rectorseal. “Given the product quality control procedures we employ, we’re confident that offering a warranty on select products demonstrates our dedication to provide our customers best in class products and support. The Limited Warranty coverage not only defines the products that we offer but is a reflection on the strength and innovation associated with the entire company.”

The enhanced warranty coverage will be supported by aggressive in-store merchandising at RectorSeal distributors and sales representative locations.

No registration is required to activate any of the limited warranties offered by RectorSeal. Underwood adds, “Along with providing outstanding limited warranty coverage, we wanted to make the warranty claims process as easy as possible. Ours is not a multi-step process. The entire claiming process takes only a few minutes.”

All standard warranty claims are administered by the local RectorSeal distributor or sales representative.

Beyond the limited warranty coverages, RectorSeal offers a robust selection of sales and technical training classes at no cost. “Our total support package to customers is designed to ensure that any concerns are quickly resolved. Our customers expect the best products, limited warranty coverage, and support services because RectorSeal is an industry leader,” said Underwood. “And, we deliver on those expectations every day.”

Golterman & Sabo Celebrates 75th Anniversary

Golterman & Sabo, an acoustics and architectural products company, is celebrating 75 years of serving the construction community. Founded by Herbert Golterman Sr. in 1946, the award-winning company has remained a family-owned and operated business since its creation. Now in 2021, the original Herbert Golterman Company is known as Golterman & Sabo. The company manufacturers acoustical products for global distribution, plus supplies an array of architectural products and installation services to the Midwest region.

In its third generation of family ownership, Golterman & Sabo is the parent company of G&S Acoustics, G&S Architectural Products, FabricWall and G&S Cinema Acoustics. While one aspect of the family business G&S Acoustics focuses on improving the quality of sound or dampening noise with innovative acoustical products, the sister company G&S Architectural Products distributes and installs operable walls, window shading systems, and a variety of other specialized architectural products. FabricWall is an acoustical stretch fabric system for walls and ceilings. The last division is G&S Cinema Acoustics which creates custom, high-quality sound absorbing panels for turn-key theater applications from field measuring to installation.

“With a unique mix of acoustical and architectural products, as well as the manufacturing and installation services we provide, we’ve found our niche,” said Herb Golterman, CEO of Golterman & Sabo, and grandson of the company’s founder. “It’s an honor to carry on the family business and know that we are growing the company for future generations. That includes several of our employees who have been with us for many years and are very much like family.”

This year, G&S Architectural Products received the Specialty Subcontractor of the Year Award from the American Subcontractors Association Midwest Council. The annual ASA Gala honors the achievements of general contractors, subcontractors, and suppliers in the greater metropolitan area of St. Louis, as well as in the southern Illinois region.

This is the sixth time that G&S Architectural Products has won this award, having been nominated a total of 10 times since the award’s inception in 2001. This accomplishment means a lot to G&S. Subcontractors are nominated and selected for the annual ASA awards by general contractors, who place their votes based on bid ethics practice, safety policy and practices, jobsite supervision, scheduling coordination, and project relations.

In addition to the ASA Specialty Subcontractor of the Year Award, G&S has won other numerous construction industry awards. Many projects in which G&S has been involved with have won either CISCA or Keystone Awards.

Nonresidential Construction Sector Posts First Job Gain Since March

The construction industry gained 22,000 jobs between August and September as nonresidential construction firms added employees for the first time in six months, according to an analysis by the Associated General Contractors of America of government data released. Association officials said nonresidential construction has been affected by the widespread supply chain problems, which are causing owners already uncertain about future demand for commercial space to delay or even cancel some projects.

“While it is refreshing to see job gains in both residential and nonresidential construction, nonresidential building and infrastructure employment remains far below its pre-pandemic peak,” said Ken Simonson, the association’s chief economist. “It will take more than a few months of gains to match the overall economy.”

Construction employment in September totaled 7.4 million, an increase of 22,000 since August. However, industry employment remained 201,000 below the pre-pandemic peak set in February 2020.

The nonresidential segment, comprising nonresidential building and specialty trade contractors plus heavy and civil engineering construction firms, added 18,600 employees in September. But nonresidential employment is 281,000 below the February 2020 level, as the sector has recovered only 56 percent of the jobs lost in the first two months of the pandemic.

Residential construction—including building contractors such as homebuilders, along with residential specialty trades—added 3,600 employees in September. Residential employment tops the February 2020 mark by 80,000.

Simonson cited an unending series of supply-chain bottlenecks, as well as extreme price increases and long lead times for a variety of construction materials, as threats to further growth of nonresidential construction. He said he had heard about an increasing number of project owners deciding to postpone projects because of excessive cost increases and lead times. He noted that the association has again updated its Construction Inflation Alert, a guide to inform owners, officials, and others about the cost and supply-chain challenges.

Association officials urged the Biden administration to remove tariffs and import quotas on a range of key construction materials to help address supply chain disruptions. They added that Congress can help offset declining nonresidential demand for construction by passing the bipartisan infrastructure bill that has already cleared the Senate.

“Both parties in the House should make passing the infrastructure bill a top priority because it is the best way to create new construction careers and make our economy more efficient,” said Stephen E. Sandherr, the association’s chief executive officer. “If the President acts to address supply chain problems and Congress passes the infrastructure bill, construction employment is likely to surge.”

ICC and RESNET to Develop Standard on Remote Virtual Inspections for Building Performance

The International Code Council, a source of model codes and standards and building safety solutions, and RESNET, a national standards-making body for energy efficiency ratings and certification systems, will continue their long history of collaboration by developing a new American National Standards Institute candidate standard on remote virtual inspections for the energy and water use performance of buildings. Previously, the two organizations have worked together to develop a new certification designation, the International Energy Conservation Code/Home Energy Rating System Compliance Specialist, and four other ANSI standards. Most recently, they advocated and received recognition of the Home Energy Rating System Index within California.

The new standard will provide guidance for implementing RVI for energy code compliance and for energy and water efficiency performance. Performance raters will be provided criteria to check all aspects of permitted construction for compliance with energy codes and other energy-related applicable laws and regulations. As a next step, a new Standard Development Committee will be formed to develop and maintain the standard with the Code Council and RESNET appointing representatives – both separately and jointly.

“Building construction is rapidly evolving and jurisdictions are being challenged to adapt,” said Mark Johnson, executive vice president and director of business development, International Code Council. “The need for new inspection methods has been building for a while as the inspector workforce has shrunk and jurisdictions’ resources have come under financial pressure. The pandemic also increased the pressure to evolve, and quickly.”

RVI is a tool to address these problems and organizations such as the Code Council have developed guidance documents to assist code enforcement entities.

“As more code enforcement departments begin their digital transformation and adopt technologies like RVI, there needs to be standardized criteria for how it is implemented,” said Steve Baden, executive director, RESNET. “A national consensus standard for RVI as it applies to energy- and water-use efficiency inspections and ratings will both provide code enforcement authorities with assurance that the ratings they adopt for code compliance are reliable, as well as advance the efficiency and efficacy potentials of these new approaches to determining code compliance.”

The standard would be co-sponsored by the Code Council and RESNET and developed using RESNET’s ANSI accredited procedures as an American National Standard by ANSI. For more information on RVI, the Code Council released a whitepaper, Recommended Practices for Remote Virtual Inspections, which will be the foundation for the development of the new consensus standard.

Portland Cement Association Releases Roadmap to Carbon Neutrality by 2050

The Portland Cement Association announced its Roadmap to Carbon Neutrality, an ambitious journey to carbon neutrality across the cement and concrete value chain by 2050. Given the significant role of cement in society and anticipated infrastructure development, it is a critical step that the industry act now to further reduce greenhouse gases and create sustainable building solutions in the decades to come. The Roadmap demonstrates how the U.S. cement and concrete industry, along with its entire value chain, can address climate change, decrease GHGs and eliminate barriers that are restricting environmental progress.

“Cement and concrete have been pivotal in building resilient, durable and sustainable communities that enable people to live safe, productive and healthy lives via structures that withstand natural and man-made disasters,” said PCA President and CEO, Michael Ireland. “PCA is uniquely positioned to lead the industry-wide ambition to achieving carbon neutrality and enable our member companies and industry partners to continue building a better future.”

The PCA Roadmap outlines a portfolio of reduction strategies and immediate opportunities across the various phases of the built environment: production at the cement plant, construction including designing and building, and everyday infrastructure in use. Across this full cement-concrete-construction value chain, the Roadmap recognizes five main areas of opportunity: clinker, cement, concrete, construction and carbonation (using concrete as a carbon sink). Each phase of the value chain is integral to reaching the goal and can unlock unique and specific pathways to carbon neutrality, including actions such as reducing CO2 from the manufacturing process, decreasing combustion emissions by changing fuel sources and shifting toward increased use of renewable electricity.

“Drawing on their expertise from producing the majority of cement in the U.S., PCA member companies felt strong partnership across the industry to identify the challenges manufacturers face and the opportunities and potential solutions in achieving carbon neutrality,” said Ron Henley, PCA Chairman of the Board, and President, GCC of America, Inc. “We also understand the unequivocal value external collaborators have in implementing and moving sustainable solutions forward, and we are committed to working alongside government, science and technology leaders to bring our Roadmap to life.”

PCA is committed to gathering a coalition of industry experts, researchers, policymakers and companies along the value chain to make this Roadmap a reality. Collaboration with leaders is imperative to realize the multitude of solutions that must be developed across policies and regulations, technology and innovation and demand generation, creating both near- and long-term reduction opportunities.

Many of the solutions included in the PCA Roadmap are products, technologies and approaches that exist today—and by bringing together a variety of collaborators, PCA intends to ensure the adoption of these solutions on a broad scale. This will accomplish near-term benefits while constantly striving toward the long-term success of reaching carbon neutrality.

“PCA is actively engaging with organizations beyond the industry to bring the right people to the table to accelerate and advance solutions to reach carbon neutrality,” said PCA Climate and Sustainability Council Co-Chair, and President and CEO Massimo Toso and Buzzi Unicem USA. “Our Roadmap is an open-source, collaborative effort and includes stakeholders directly involved in the value chain as well as those not directly involved in the value chain.”

“Achieving carbon neutrality across the entire value chain by 2050 will require industry development of an entirely new set of metrics, means and methods to track the industry’s Roadmap progress,” said PCA Climate and Sustainability Council Co-Chair, and U.S. CEO of National Cement Company Eric Holard, “Once we have established effective measurement, PCA companies are committed to transparently demonstrating progress.”

Additionally, cement and concrete companies worldwide have committed to achieve carbon neutrality across the value chain by 2050. Addressing climate change is a global task, but each country presents specific opportunities and challenges, and the PCA Roadmap presents a plan for the U.S. cement and concrete industry. PCA is aligned with the Global Cement and Concrete Association’s Roadmap.

PCA’s comprehensive industry-wide approach will allow America’s cement manufacturers to continue to deliver this critical material, while empowering the industry and others to collaborate toward a shared mission of achieving carbon neutrality by 2050.

FCIA Special Alert: UL Numbering System

UL has announced a new numbering system for firestop systems and fire-resistive joint systems. Two categories are moving from a 4-digit System Number (C-AJ-2999) to a 5-digit System Number (Example, C-AJ-20000). It’s not a massive change or overhaul, but it’s important to understand to avoid confusion and ensure proper system selection and analysis – proving continued value of a Qualified Firestop Contractor.

FCIA is with you during this change. Resources to help FCIA Members understand the change are posted on FCIA’s Technical Resources Page, and UL’s Resources Page. Also, check out this link too: UL Numbering Systems for Penetration Firestop Systems and Joint Systems.

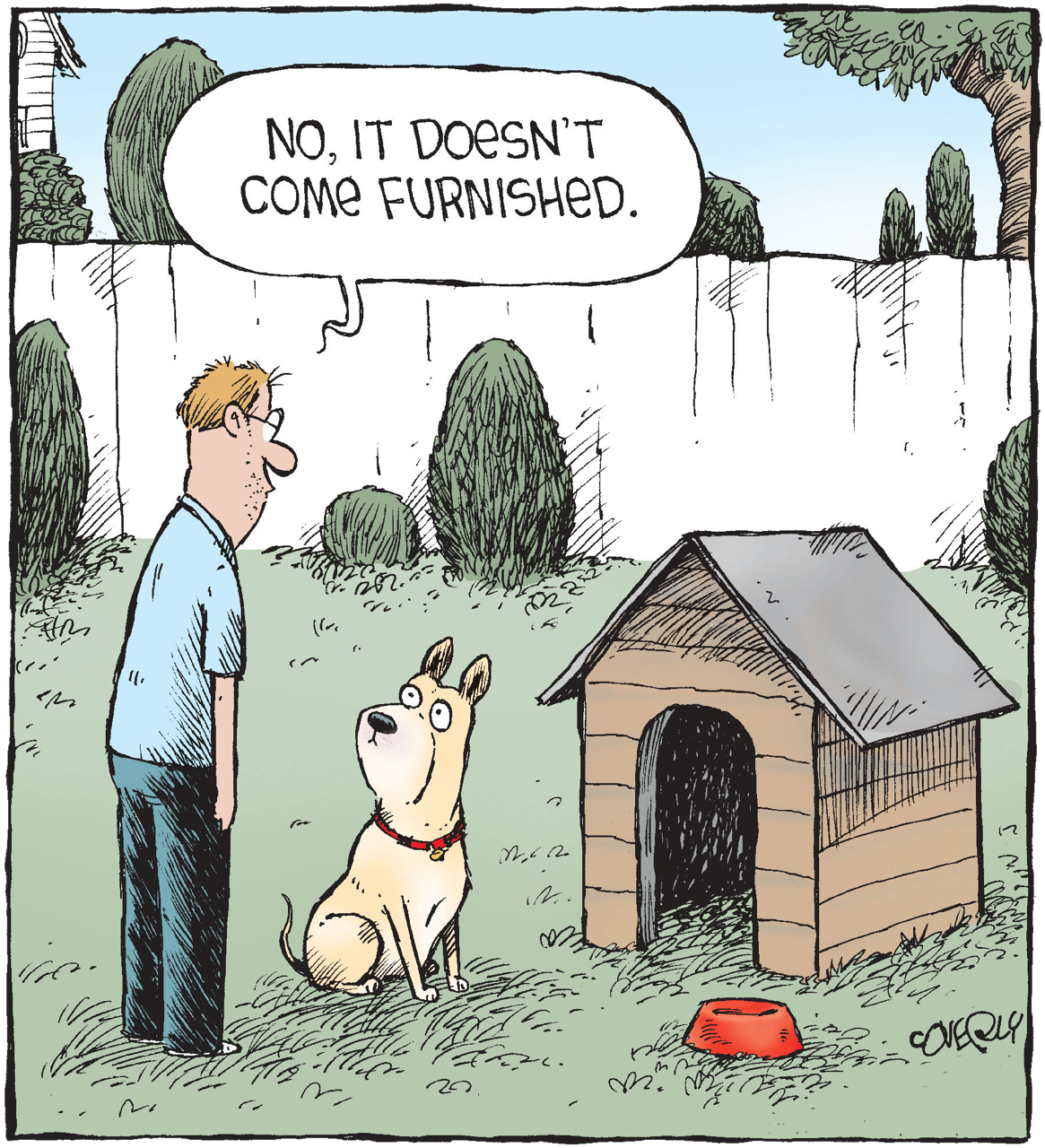

Spackle by Dave Coverly

People News

CUPACLAD America has announced the appointment of Michael Meyer as the firm’s Eastern Region Sales Manager.

L&W Supply has announced that Curt Jenkins, former district manager for Texas, has been promoted to central region vice president. The distributor has also announced that Trish Boomsma has been named branch manager of the Grand Rapids, Mich., location.

Plastic Components announced that Buddy Ayala has joined its nationwide network of sales representatives.

Petersen has promoted its Southeast Regional Manager Mike Weis to vice president, sales and marketing.

Altenloh, Brinck & Co. U.S. Inc. announced that Brett Katsma joined the company as product manager focusing on structural applications.

Scroll Down

Scroll Down