Firestopping &

Fire-Resistance

A rundown of tested and listed systems—specified and codified.

By Bill McHugh

Before we talk about firestopping, fire-resistance-rated assemblies have to be built to become a fire-resistance-rated assembly. The International Building Code—and NFPA 101, The Life Safety Code; NFPA 1, The Fire Code—all have references to the legacy fire-resistance test standards, ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, and UL 263, Standard for Safety of Fire Tests of Building Construction Materials.

After a successful fire-test, the test sponsor, usually a manufacturer, requests the listing be published in the test laboratory directory and sometimes the results remain private. Some public directories are online. UL, FM Approvals, and Intertek have their own directories. And of course there are probably other listings available online from test labs not mentioned here. The key thing to remember is the fire-test is a proven way to provide a fire-resistance-rated assembly.

The listing mentions key installation specs, fastener types and spacing, etc. Without the system description, the contractor has no idea how to assemble an assembly that is fire-resistance-rated. There is no way to install firestopping, or other fire-resistance assemblies, without having BOTH the listing and the manufacturer's installation instructions.

Horizontal Assembly

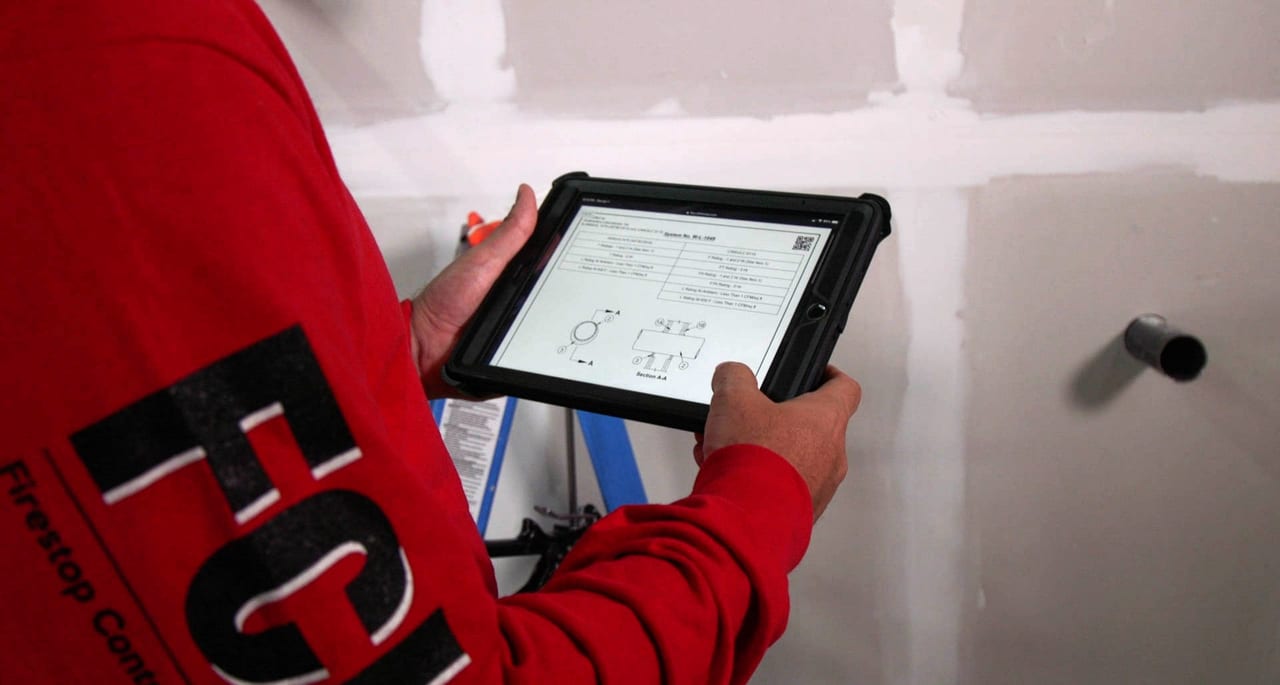

The horizontal assembly—a floor or roof—is built in accordance with a listing or other methods as prescribed in the applicable building code. Gypsum panel walls are built in accordance with the listing—shown in the below image. The listing will have details about the type, thickness, spacing, gauge of studs, fastener type and spacing, joint treatment, board orientation, whether joints need to be offset or not, whether insulation is included or not, the acceptance criteria, and much more.

While the finished product looks like a wall, due to the rigorous fire-testing including the hose stream test, it has to perform different than a regular wall. Assembly and patching therefore, have to be in accordance with the tested and listed assembly. Patching fire-resistance-rated gypsum panels isn’t as easy as just taping and mudding. The Gypsum Association’s document GA-225 shows the method to repair gypsum panels to resist fire, temperature and the hose stream test.

The Details of Firestopping

Firestopping, for both penetrations, joints and perimeter fire barriers, is no different when it comes to fire-testing. A tested and listed system is needed to restore the wall or floor to the fire-resistance-rating it had before a breach was made in the assembly. Even the simple looking applications have detailed listings that then have to be installed in accordance with the manufacturer’s installation instructions.

The tested and listed systems state minimum annular space sizes, spacing between penetrating items, joint or gap size, if there are penetrating items at the head of wall, perimeter fire containment system, etc. And, when it says minimum and maximum in the listing, it means it. Any variances beyond what the system listing describes violates the system, meaning performance is unknown—and a safety risk.

The firestop industry has been evolving for the past three decades, and it’s been evolving fast. What started as just protecting “penetrations,” has evolved into what we now call "firestopping." Which includes:

- Penetration Firestop Systems: Single or Multiple

- Fire-Resistive Joint Systems: Head of Wall, Wall to Wall, Bottom of Wall, Floor to Wall, Head of Fire-Resistance-Rated Wall to Non Rated Roof

- Perimeter Fire Barrier/Containment Systems

Test standards have been developed to evaluate products used in these assemblies and suitable for use in the specific applications providing fire, temperature, and if tested, air leakage, movement and other properties required by the building use.

Specifications since the early 1990’s have stated that products are to resist what’s expected to occur in the building in addition to fire-resistance. The International Building Code has requirements for F, T, and L-Rating in firestopping. The L-Rating is used in smoke barriers. A quite specific use.

Requirements for firestop systems were developed at the inception of the test standards, with new ancillary standards developed at ASTM and UL/ULC to help reflect what actually happens to the products in buildings to meet specification and code requirements.

Below is a listing of key ratings for firestopping:

- F-Rating: How long does it take for fire to poke through the assembly to the non-fire-exposed side?

- T-Rating: How long does it take the penetrating item, to increase in temperature to 325 degrees Fahrenheit above ambient?

- The F&T Ratings have been around since the inception of the standards, in the early 1980s.

- L-Rating: What is the air leakage, stated in cubic feet per minute of air flow through the assembly, per square foot of opening area–simulating smoke movement? This was introduced around 1994.

- W-Rating: Does water leak through the firestop assembly with a 3-foot head of water, exposed for 72 hours, with conditioned material, when not moved or exposed to chemicals? This is in UL 1479 and UL 2079 only, and not in the ASTM Standards. This was introduced in the late-’90s.

- M-Rating: What movement can the firestop system resist in the X or Y axis? The new M Standard is not for people jumping on pipes, but simulates water hammer, thermal expansion. This is quite new, and a result of an FCIA request to the manufacturers in 2008. Yes, it takes 10-plus years to build new standards. This standard, ASTM E 3037, is the standard test method for measuring relative movement capabilities of through-penetration firestops.

- E-Exposure: ASTM E2785-Standard Test Method for Exposure of Firestop Materials to Severe Environmental Conditions, was developed due to FCIA requests for resistance statements to manufacturers. This standard is in addition to what the manufacturer might state the materials can resist in the environment based on their own internal testing. It evaluates change in physical properties, chemical properties, or both, of firestop materials after a standardized environmental exposure. Note, the standard does not cover all exposures. Verify with the manufacturer and building expectations to cover resistance required.

- H-Hose Stream Test: The hose stream test is a requirement in the International Building Code, NFPA 5000, The Building Construction and Safety Code and NFPA 101, The Life Safety Code, and other North American Codes, with a few exceptions. This test is what separates those products regulated under these codes and European Codes, where hose stream is not required.

- Assembly Rating: For joints, this rating defines the fire-resistance of the joint assembly. Listed in the assembly rating is the joint width, movement capabilities, and L-Rating.

Systems Selection/Analysis & Specialist Firestop Installation Contractors

After seeing how many ratings there are, and understanding the complexity of systems selection and analysis plus the fact that there is no “close enough” in firestopping—it’s clear there is a certain mindset required to get firestopping done right.

That’s why there are companies who specialize in this construction discipline—and have an office and field culture that is unique. This culture understands these tested and listed firestop systems and manufacturers installation instructions, respecting their rigorous attention to detail.

Why bother sticking to the systems? The International Building Code now clarifies that Firestopping—Penetrations, Joints and Perimeter Fire Barriers are to be installed in accordance with the tested and listed system and manufacturers installation instructions. Remember, if the building code requires it and it’s been adopted by a jurisdiction, it’s a law!

FM 4991: UL QFCP

FCIA’s Accreditation Committee’s work with FM Approvals (1999) and UL (2007) to build FM 4991 and the UL Qualified Firestop Contractor Program (UL QFCP), is making a difference as specifications state that a FM 4991 or UL Qualified Firestop Contractor be used on projects. These programs provide companies that understand the systems concept—both usage and limitations.

In a FCIA sponsored Dodge Data Analytics search of 07-00-00 specifications, including section 07-84-00 Firestopping, an FM 4991 or UL QFCP Contractor is specified over 40 percent of the time. Further, projects greater than $100 million in size had FM or UL Contractors specified between 52 percent and 62 percent of the time. FM 4991 & UL QFCP Contractors also are specified most in manufacturing (75 percent), dormitories (71 percent), and healthcare (55 percent).

FM 4991 & UL QFCP Contractors are also in a large-percentage of specifications for projects over $10 million USD. The point is that specs call for the two programs, which results in a firestop installation contractor that has been audited by FM or UL to have procedures in place that demonstrate the ‘systems concept’ that is needed for firestopping. And, the same discipline is required for all fire-resistance-rated assemblies that require a ‘tested and listed system’ behind the product.

Ever see “We’re ISO-9000 Approved” on a product label? That means the manufacturer has processes in place for quality.

FM 4991 and UL Qualified Contractors have a quality management system in place that focuses on field operations, systems selection, installation quality and documentation of the final as-built firestopping. FM 4991 and UL Qualified Contractors bring a management system based, independently audited quality program to the construction contracting industry—that brings a different dimension to the industry.

Maintaining Fire-Resistance Protection

It seems many know about inspecting alarm sprinkler systems and fire pumps throughout the building life cycle. But what about the fire-resistance-rated assemblies and structural fireproofing? The manufacturers of the products state that maintenance of the products is not required. However, we know that with breaches made for pipes and cables, joints, new cables or pipes can be added or changed, even in head of wall joints, violating the tested and listed system. Even though a product might state “no maintenance required,” the fire-resistance protection needs to be maintained.

The International Fire Code, NFPA 101, The Life Safety Code, NFPA 1, The Fire Code, and other codes around the world basically state that fire-resistance-rated assemblies need to maintain continuous protection in buildings.

The International Fire Code then goes further and states that an annual visual inspection by the owner (building owner or owners agents) take place. The assemblies are to be “properly repaired, restored or replaced where damaged, altered, breached or penetrated. Records of these inspections and repairs are to be maintained by the owner.” Excluded from inspection are areas that are not accessible by removal of a panel, likely where a hard ceiling is located. And, the building owner can subcontract the inspection to a barrier management services contractor if desired.

What About Firestop Inspection?

The International Building Code’s Special Inspection Chapter 17 mandates firestopping inspection in accordance with ASTM E2174, Standard Practice for the On-Site Inspection of Penetration Firestops and ASTM E2393, Standard Practice for the On-Site Inspection of Fire-Resistive Joint Systems and Perimeter Fire Barriers, for certain types of buildings. The firestop inspection standards, and the requirement to use them, is found in Section 1705.18 of the 2021 IBC.

Buildings with occupied floors that are 75’ and higher above lowest fire department access (high-rise), and Category III and IV buildings in Table 1604.5, plus residential occupancies greater than 250 people, are subject to firestop special inspection.

How did inspection get mandated? At a 1999 FCIA Conference, this questions was posed: Why isn’t there independent inspection for firestopping like there is for fireproofing? The answer: Does your industry have a standard and has it petitioned to put it in the code? That’s when the FCIA Standards Committee formed and they hired a consultant to write the first draft, then worked with the firestop manufacturers to get it approved at ASTM. FCIA was the proponent inserting the ASTM E2174 and E2393 into the 2012 version of the International Building Code. Yes, that’s a 13 year development period.

Inspection agencies need to be approved by the code official, as does the inspector. Inspection agencies need to independent of the contractor, free of conflicts, have experienced and competent personnel, plus the equipment to carry out the inspection. FCIA worked with International Accreditation Services to build IAS AC291’s Firestopping section, resulting in a management system-based inspection agency.

For inspection agency personnel, the FM & UL Firestop Exams, International Firestop Council Exam, and ICC Certificate of Learning Achievement, are all ways the inspector can prove firestopping competence. No certification is required by the building code. Firestop inspection agencies can prove competence using the IAS AC-291 Accreditation Program.

Firestop Inspection in accordance with ASTM E2174 and ASTM E2393 means either 2 percent of each type of firestop, no less than one of each type per for each area (area is greater than 10,000SF) of a floor when the floor is larger than 10,000 square feet. Or observation of installations can take place at the rate of 10 percent of each type of firestop installed.

For joints, visual or destructive inspection is stated in the standard practice. The frequency is 5 percent of the total linear feet of each type of fire-resistive joint system being installed.

What’s a type of firestop? It’s a firestop system design, by the firestop installation contractor. That way, when a project has multiple firestop installation companies, ALL are inspected equally.

What does inspection mean? With competent inspection agencies and inspectors, quality is checked, and performance is better. It also means that contractor productivity could be slowed, to accommodate the inspection.

Repairing Firestop Materials and Systems

When destructive inspection is employed, repairing the firestop system is critical to performance. Following the tested and listed systems and manufacturers repair instructions is imperative, or fire-resistance can be compromised. If there are no instructions on the product data sheets, ask for them in writing.

As mentioned, firestop inspection is mandated by the building code. Repairs will be needed as many building owners and managers are choosing the ‘destructive method’ of firestop inspection, as it can be less expensive than the observation method.

The FM 4991 & UL Qualified Firestop Contractor programs are in a large percentage of specifications—and used on key projects including the U.S. General Services Administration, and much more.

Conclusion

This industry has evolved a lot in the last 30 years, with manufacturers inventing products, contractors figuring out how to install them, inspection agencies appearing, and much more. This industry will continue to change and evolve—as the general contractors, building owners, and managers figure out how this discipline is to be bought, inspected and maintained. It has its own specification section, and many GC’s are buying it separately—to assure a smooth inspection.

Want to become a student of firestopping? Check out FCIA’s Firestop Manual of Practice, The Standard. This document has been used for 21 years—and acts as the firestop industry “body of knowledge.”

Images courtesy of FCIA.

Bill McHugh has been FCIA’s Executive Director since 1998. He speaks, writes and works with contractors internationally. He can be reached at bill@fcia.org.

Scroll Down

Scroll Down