Specifying the Optimal

Head of Wall Framing Assembly

for Your Next Project

Which head of wall framing method is right for you?

By Chuck Webb

Cold-formed steel is one of the most widely used framing materials because of its ability to provide strength and stability in a number of conditions. A well-designed framing system can accommodate forces imposed on the structure by gravity, wind uplift and seismic activity. A key element of this design is the system’s ability to account for vertical movement of structural elements like floor systems and roof systems by allowing them to deflect downwards or upwards without imposing axial loads to the wall stud members or to the gypsum wall board (or other wall substrates).

Wall framing often bears on the top of the slab of one floor level and frames to the underside of the floor or member(s) above. This is called infill framing or slab-to-slab framing. Where this occurs, a deflection joint (or gap) is required if the wall framing needs to account for the compression or extension movement of the structure.

The deflection joint is the distance between the top of the stud framing to the underside of the substrate above (floor member or roof member) as defined by the architect or structural engineer. The top of the gypsum wall board to the underside of the substrate should also equal the same distance as the stud to substrate.

The performance of the connections holding all framing elements together is critically important, especially in coastal and high-seismic zones where structures face greater risk of movement, stress and loading from natural events like earthquakes and high-velocity winds. However, a growing number of assembly methods can make head of wall framing confusing to navigate. Let’s compare a few of the head of wall framing methods in use today.

Some deflection clips, like ClarkDietrich YurClip, require no screws at all and can be installed either on the deflection track or on the stud for a streamlined installation.

Slotted deflection clips are a versatile option that can deliver optimal results regardless of the installer’s skill or experience and can also deliver significant costs savings and efficiencies. In these assemblies, deflection is handled by the clips rather than the track itself.

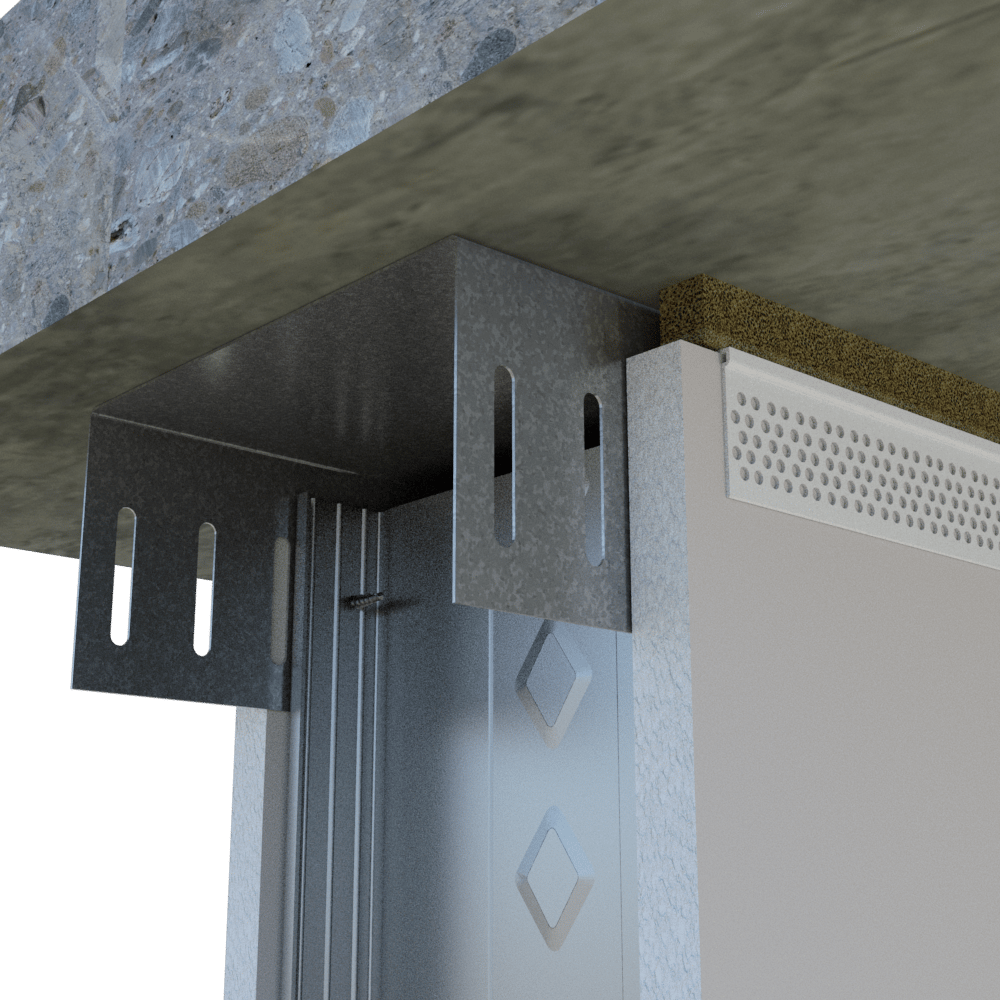

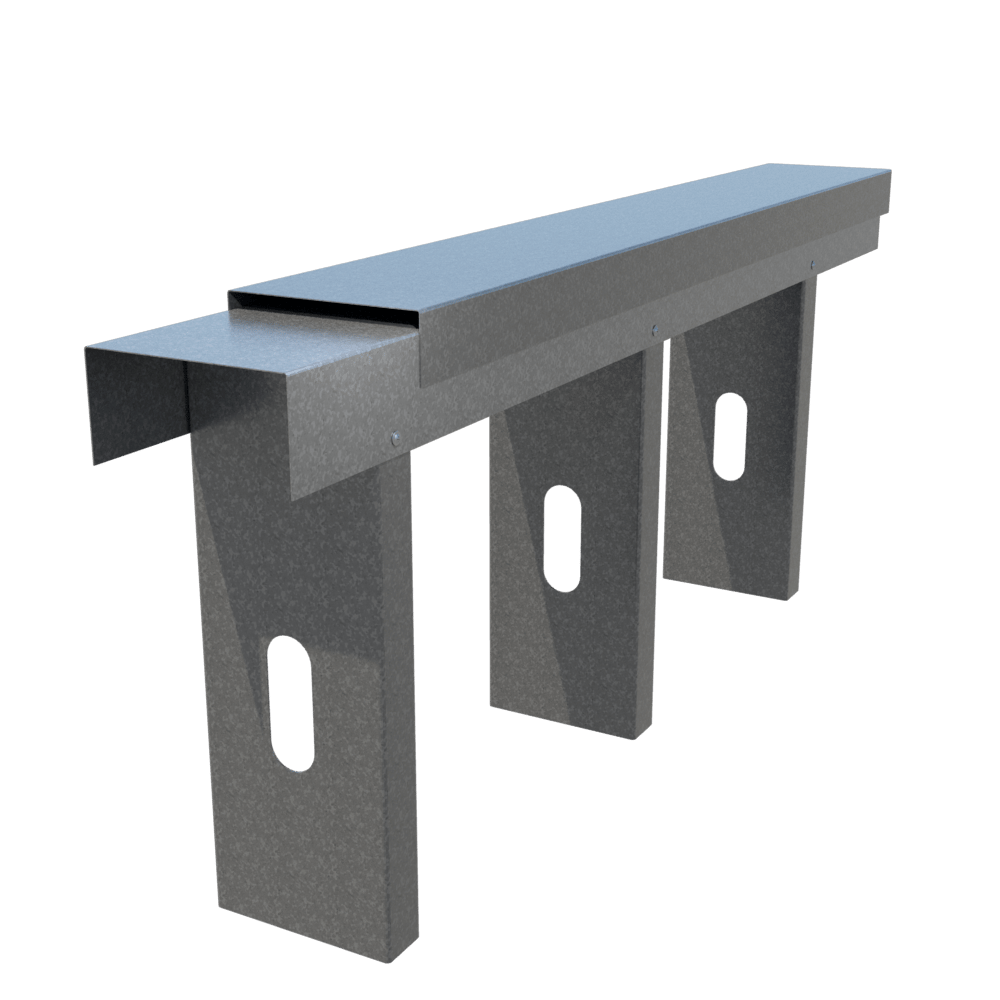

A double track head of wall assembly involves a custom-made deep leg outer track that is installed to the underside of the floor deck.

The UltraTRAK slotted system utilizes a slotted deflection track in conjunction with ClarkDietrich UltraBEAD to provide a 1- or 2-hour rated assembly for a ¾” max joint and is UL 2079-Fifth Edition compliant.

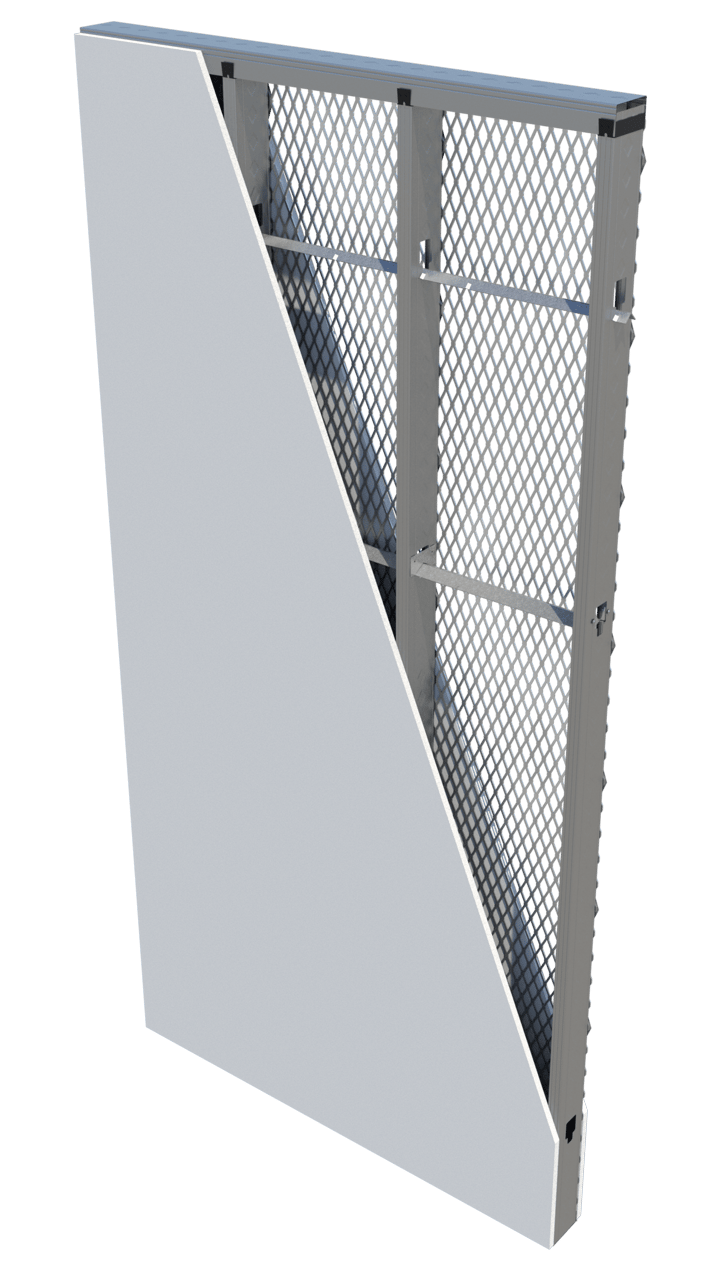

Traditional Double Track

One method of incorporating deflection into head of wall framing is a double track assembly. This method involves a custom-made deep leg outer track that is installed to the underside of the floor deck. A wall assembly is constructed on the floor and slid into place, with a gap at the top to allow for deflection.

However, this type of track-over-track assembly is becoming less and less common. That’s because the development of more innovative deflection systems has significantly improved and streamlined the assembly process.

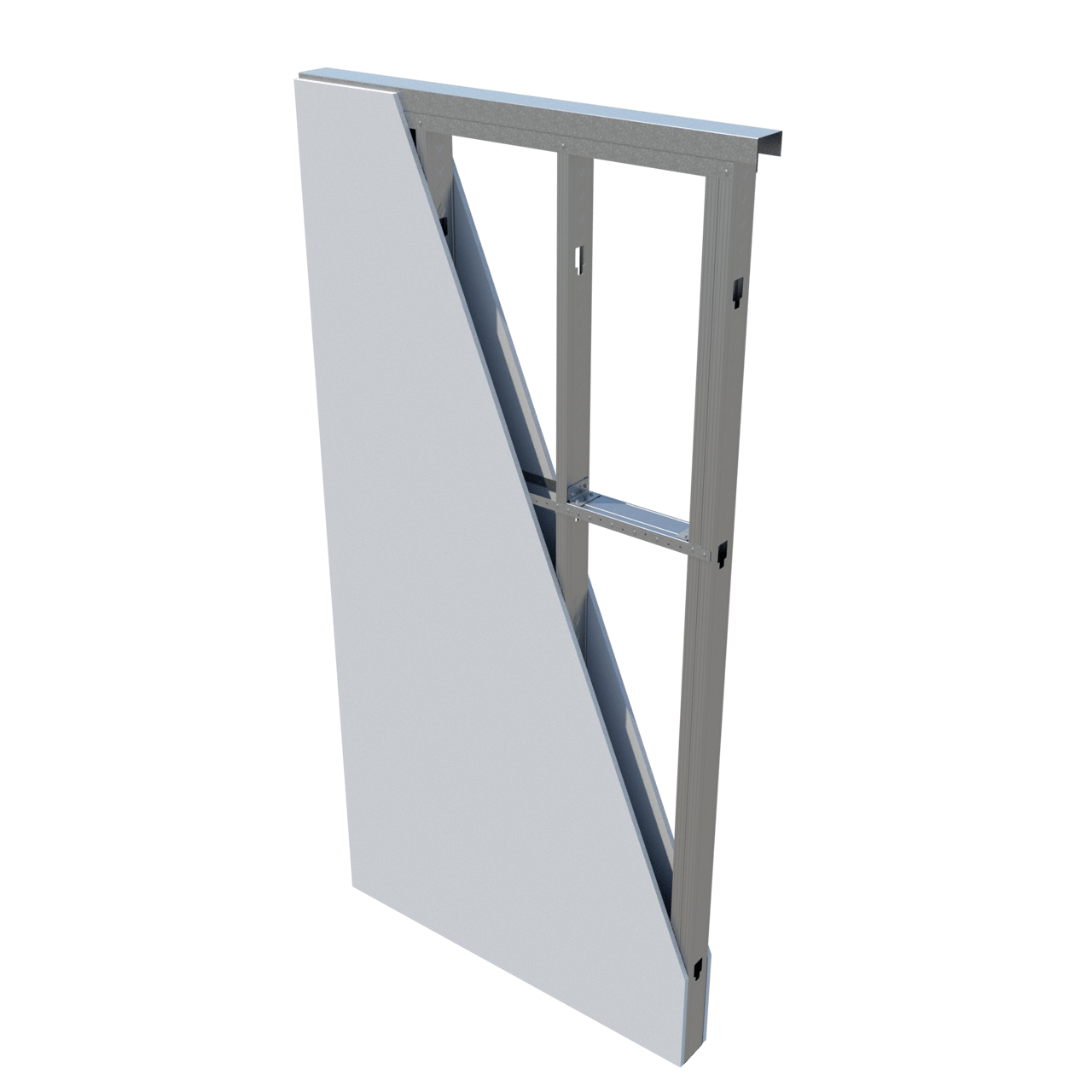

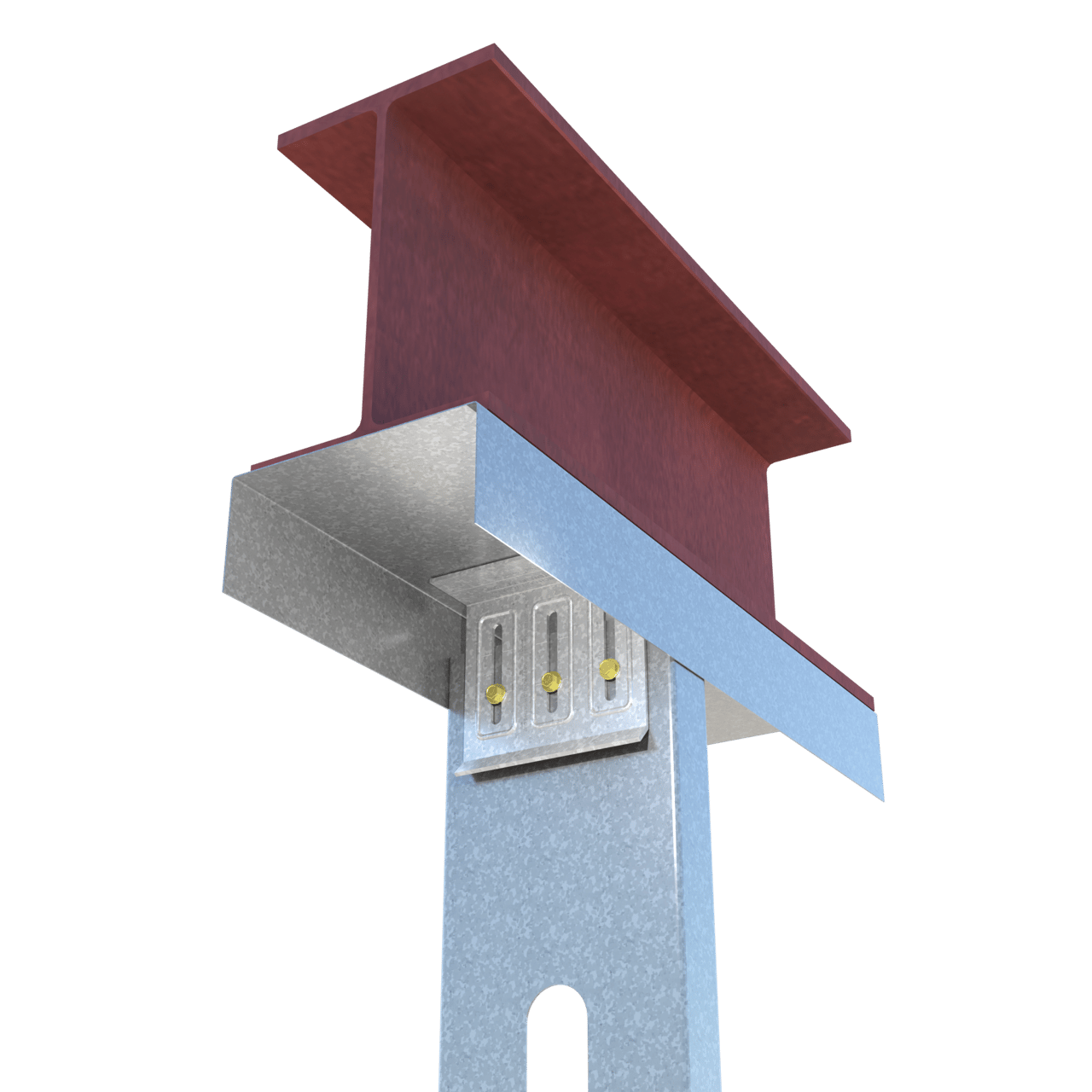

Slotted Track

A newer, more resilient head of wall framing method is a slotted track system. As their name indicates, these assemblies include tracks with vertical slots in the track legs. The wall stud framing members are secured to the deflection track utilizing waferhead screws through the center of the vertical slots on both track flanges. This allows the primary structure to compress or extend without imposing axial loads on the wall studs. And because the wall studs are secure at both flanges, stud rotation is prevented eliminating the need to add lateral wall bridging 12 inches down from the top of the stud.

Since they are a one-piece system, slotted track assemblies reduce head of wall framing material costs and will reduce labor costs because of their ease of install. They are versatile and can be used for both interior non-load-bearing walls and exterior curtain wall systems. And some products even include embossed guidelines at the center of the vertical deflection slots to help installers get comfortable with where to position fasteners accurately and quickly.

Despite their benefits, slotted track assemblies aren’t ideal for every project. Slotted track systems are typically limited to 2-inch total deflection (1-inch compression, 1-inch extension), so if a larger gap is required, a deep leg or oversized runner track may be preferable. Also, because they are a relatively new method of head of wall framing, installers may find there is a bit of a learning curve with slotted track systems.

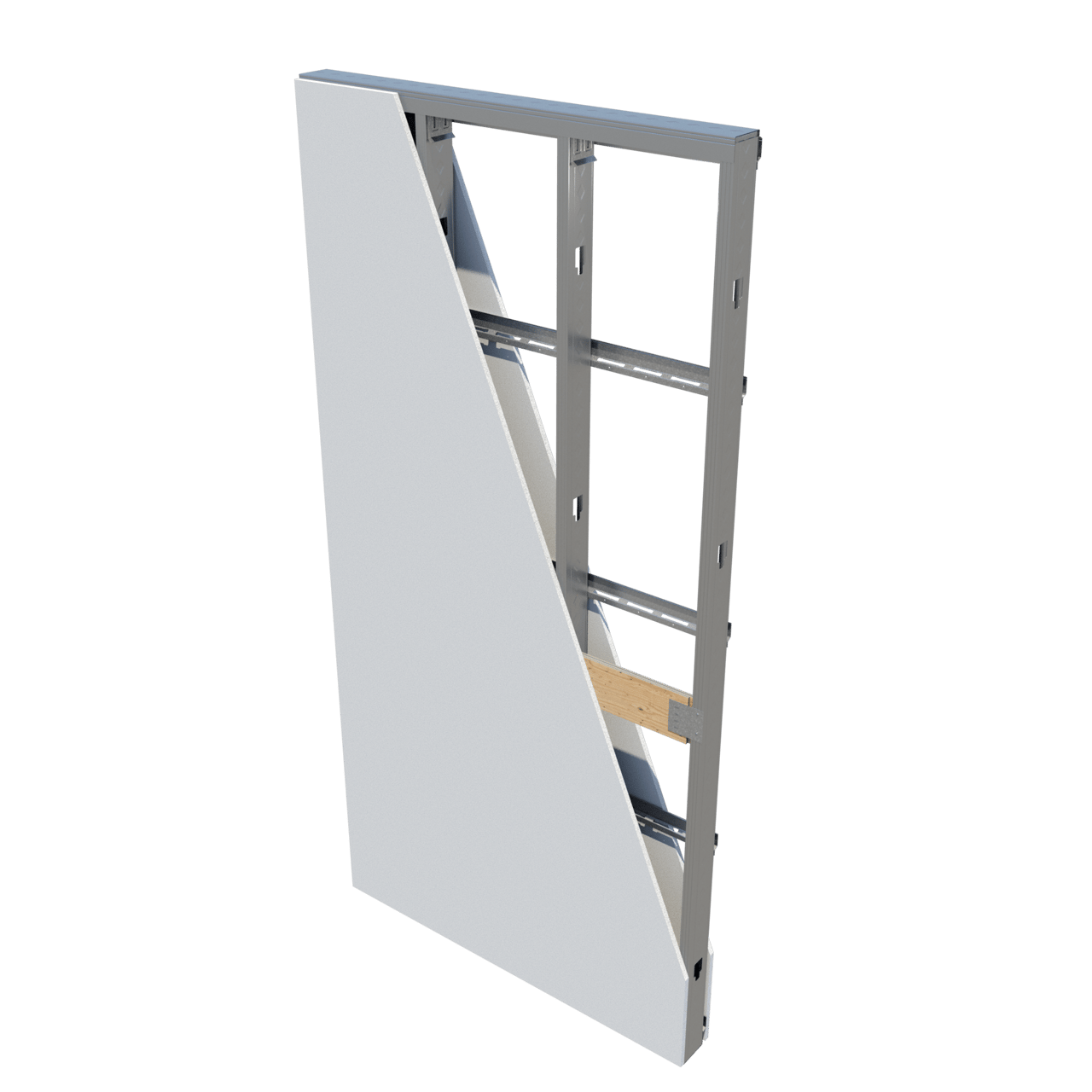

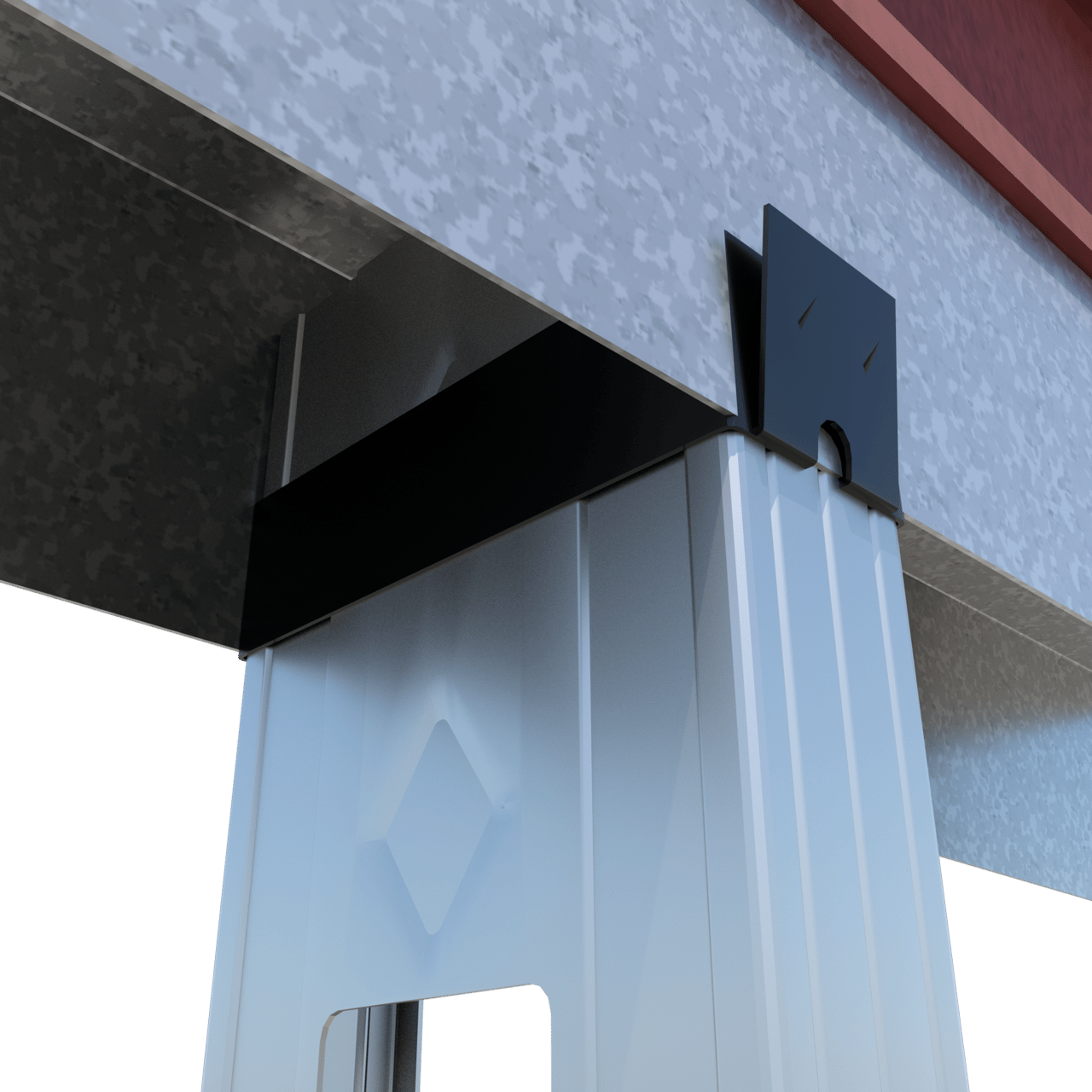

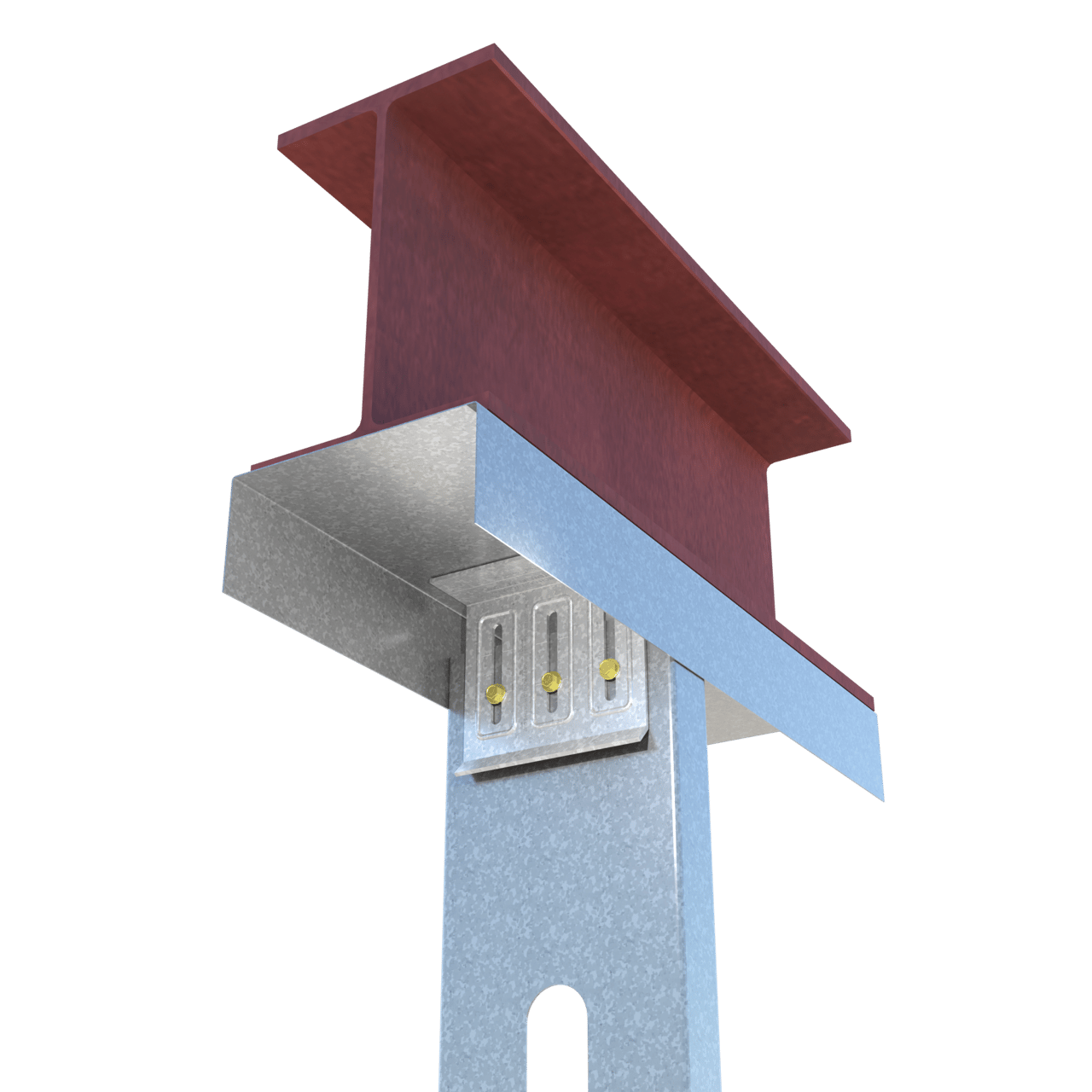

Deep Leg Track with Deflection Clips

Deep leg track paired with deflection clips provide a versatile option that can deliver optimal results regardless of the installer’s skill or experience and can also deliver significant costs savings and efficiencies. In these assemblies, deflection is handled by the clips rather than the track itself. An example would be the Fast Top Clip that features a solid leg and slotted leg and is designed to be used in place of or in combination with deflection track for in-fill curtain-wall assemblies to provide for vertical movement. The solid leg is affixed to the substrate and the slotted leg is attached to the stud web with proprietary screws that provide frictionless deflection. These clips are also embossed with fastening patterns to ensure accurate placement of fasteners.

Other deflection clips are available that require no screws at all. This type of clip can be installed either on the deflection track or on the stud members, further streamlining installation.

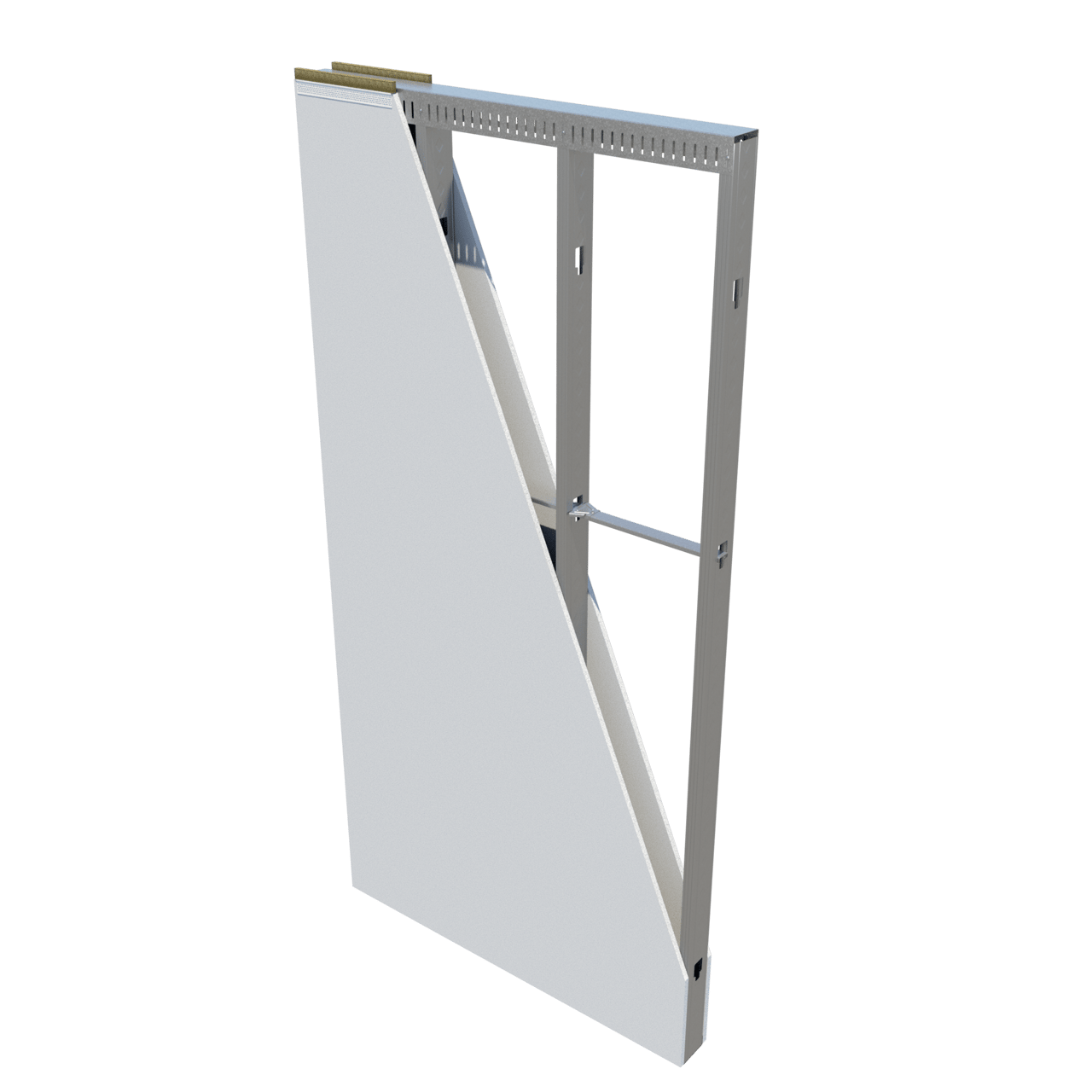

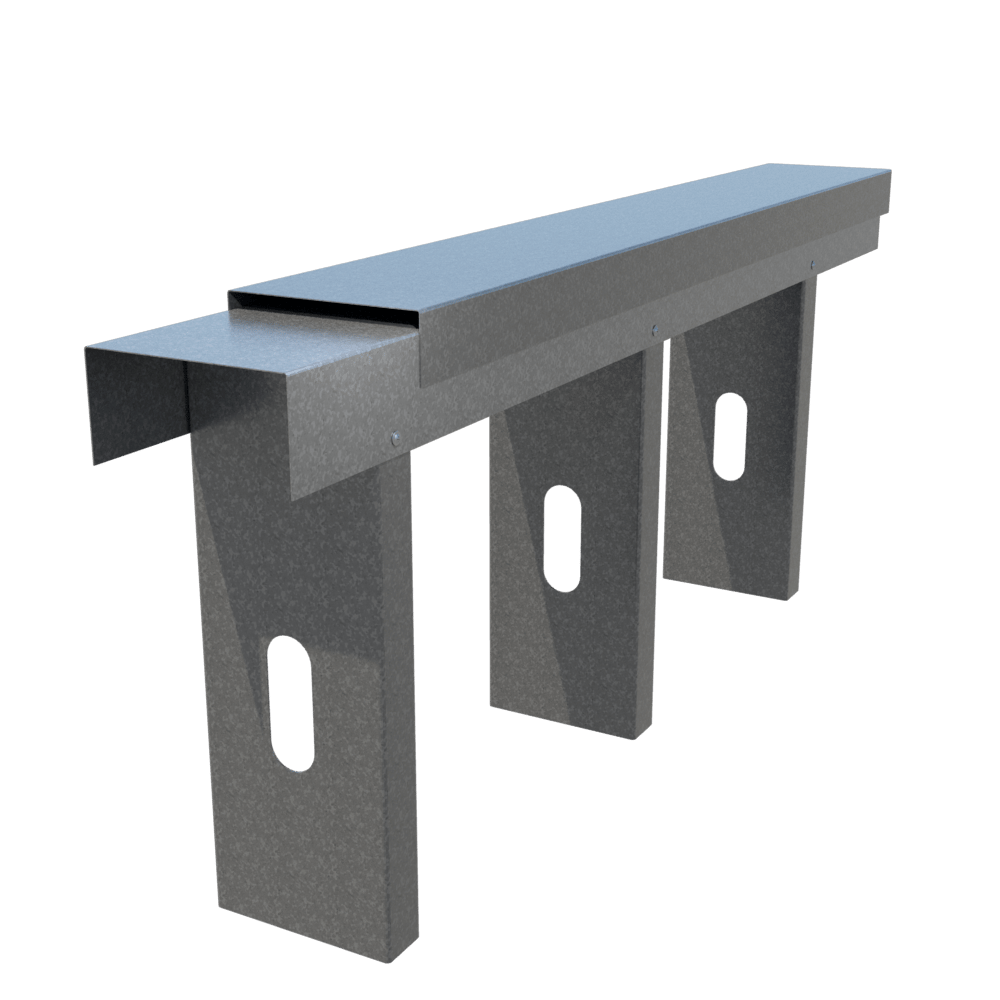

Rip Track

In fire-rated assemblies where a larger deflection gap is required, a rip track system may be a good solution. A rip track is a deflection track with an offset shoulder that represents the thickness of the gypsum board (5/8 or 1¼ inch). A second piece of gypsum board is fit flush to the underside of the slab or to a fluted deck and is then fastened to the shoulder. This allows the roof/floor assembly and the rip track to move in relation to the wall assembly. This also allows the wall cladding strips (the rip board) that is attached to the rip track to slide over the primary wall assembly.

A rip track assembly can accommodate up to a 4-inch deflection joint, which is often required in large data center facilities.

The UltraTRAK slotted system utilizes a slotted deflection track in conjunction with ClarkDietrich UltraBEAD to provide a 1- or 2-hour rated assembly for a ¾” max joint and is UL 2079-Fifth Edition compliant.

Some deflection clips, like ClarkDietrich YurClip, require no screws at all and can be installed either on the deflection track or on the stud members first for a streamlining installation.

ClarkDietrich BlazeFrame RipTRAK is the only UL tested fire-rated head of wall joint system that offers an alternate listing by eliminating castle cuts and sealant in fluted deck assemblies and that meets UL 2079, 5th edition.

Fire Protection at Head of Wall

Aside from accommodating structural deflection, head of wall framing assemblies often also include requirements for fire and smoke protection. If deflection is required in a fire-rated wall assembly, then the head-of-wall deflection joint must be protected. In these cases, the aforementioned framing methods can be used in conjunction with 3rd party fire-rated products such as fire caulks or mineral wool and sealant. However, there are more labor-friendly options.

Some deflection track products—both slotted and deep leg—incorporate an intumescent strip on each track flange that expands in a heat event to protect from heat and flame passage. One major benefit of this approach is that it allows for deflection of the primary structure while maintaining fire and smoke protection. This means the structure can compress or extend as needed by design and still maintain the integrity of the joint.

Depending on the building design, you may also be able to meet the latest fire code without the inclusion of intumescent materials. UltraBEAD is a proprietary compressible foam that provides a 1- or 2-hour fire-rated assembly under concrete floor decks for a 3/4- max joint and is UL 2079-Fifth Edition compliant. Eliminating the need for intumescent materials results in a lower overall head of wall material cost while providing smoke, fire and even sound containment.

A double track head of wall assembly involves a custom-made deep leg outer track that is installed to the underside of the floor deck.

Slotted deflection clips are a versatile option that can deliver optimal results regardless of the installer’s skill or experience and can also deliver significant costs savings and efficiencies. In these assemblies, deflection is handled by the clips rather than the track itself.

Slotted deflection tracks allow for vertical live load movement of the primary structure without transferring axial loads to the wall studs, which provides positive attachment to wall framing for overall wall strength. The one-piece system also reduced the number of components required to frame head-of-wall deflection systems.

A double track head of wall assembly involves a custom-made deep leg outer track that is installed to the underside of the floor deck.

Slotted deflection clips are a versatile option that can deliver optimal results regardless of the installer’s skill or experience and can also deliver significant costs savings and efficiencies. In these assemblies, deflection is handled by the clips rather than the track itself.

Slotted deflection tracks allow for vertical live load movement of the primary structure without transferring axial loads to the wall studs, which provides positive attachment to wall framing for overall wall strength. The one-piece system also reduced the number of components required to frame head-of-wall deflection systems.

Know When to Ask the Experts

Each project is unique, and with so many head-of-wall assemblies and solutions to choose from it’s easy to question which is right for any given situation. Steel framing manufacturers are committed to helping architects, contractors and specifiers identify the ideal solutions for their projects.

There’s a lot to consider when designing head of wall systems, from adhering to the latest fire protection codes to incorporating adequate deflection for the project conditions. While traditional design methods may get the job done, newer alternatives can likely reduce total head of wall costs by saving on labor and materials. It’s a great time to review how your project team approaches head of wall framing.

Images courtesy of ClarkDietrich.

Chuck Webb has more than 15 years of experience as a cold-formed steel specialty engineer, and currently as a technical sales manager for ClarkDietrich in the Southeast and Mid-Atlantic markets. In his role as a technical sales manager, Webb advises architects, specifiers and engineers on proprietary product application and works with contractors and sub-contractors on product opportunity and installation. He can be reached at chuck.webb@clarkdietrich.com.

Scroll Down

Scroll Down