Rainscreen

Product Focus on

Product Focus on

— EIFS/Stucco—

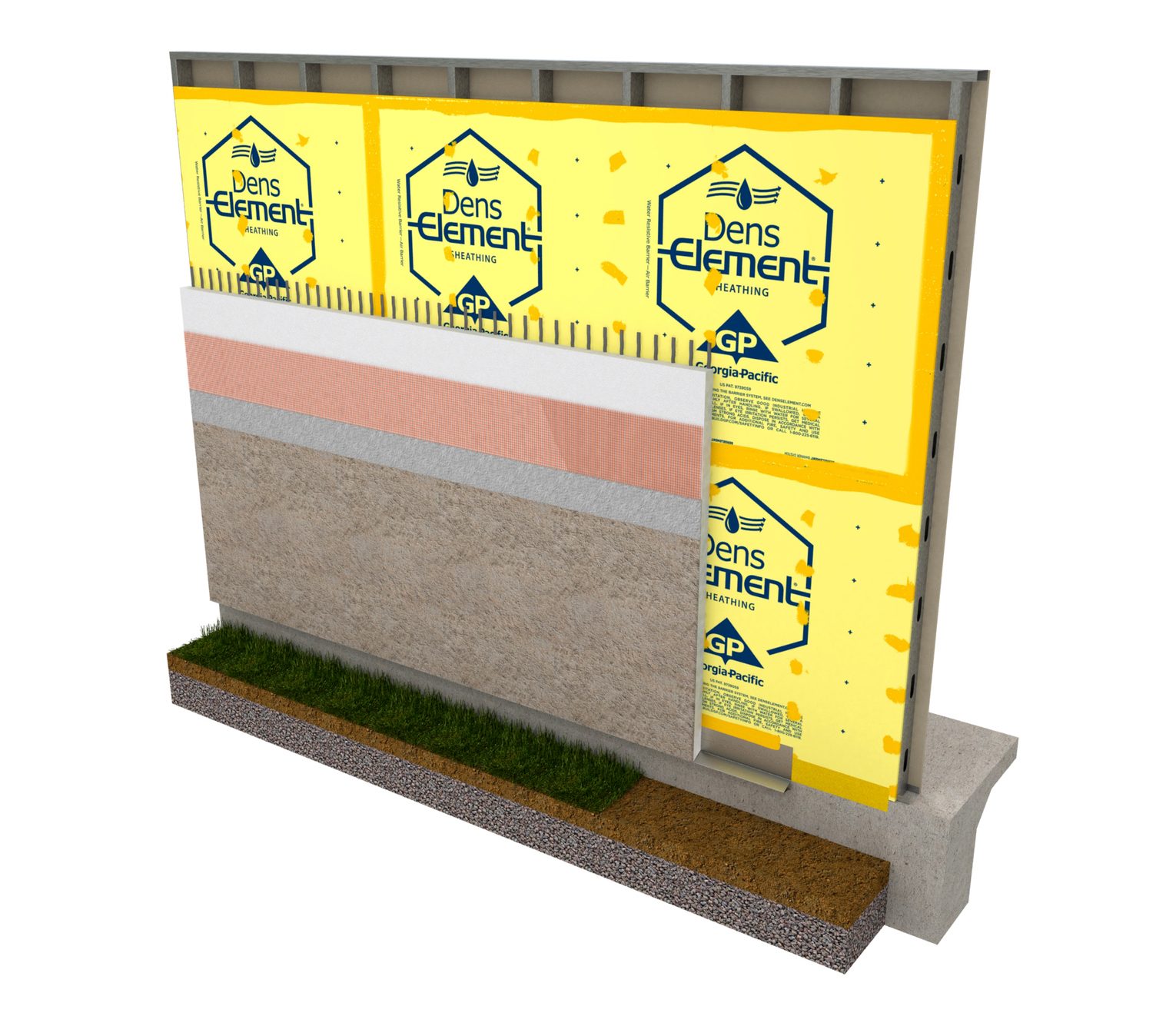

EIFS Element Barrier System

G-P Gypsum

When the EIFS system is installed, the first thing applied is a WRB-AB. What if the water- and air-resistant barrier step could be integrated into the sheathing, thus eliminating the addition of a water-resistant coating and saving a step in the installation process? With DensElement Barrier System from Georgia-Pacific, this possibility is a reality. When a substrate with integrated air and water barrier is chosen, the results are immediate: a step is removed from the construction process, saving time, money, effort and potentially even material cost. The DensElement Barrier System has gone through extensive testing—completed by third-party Intertek—and passed with the three top EIFS systems, demonstrating excellent adhesion and drainage capability. For more information, visit buildgp.com.

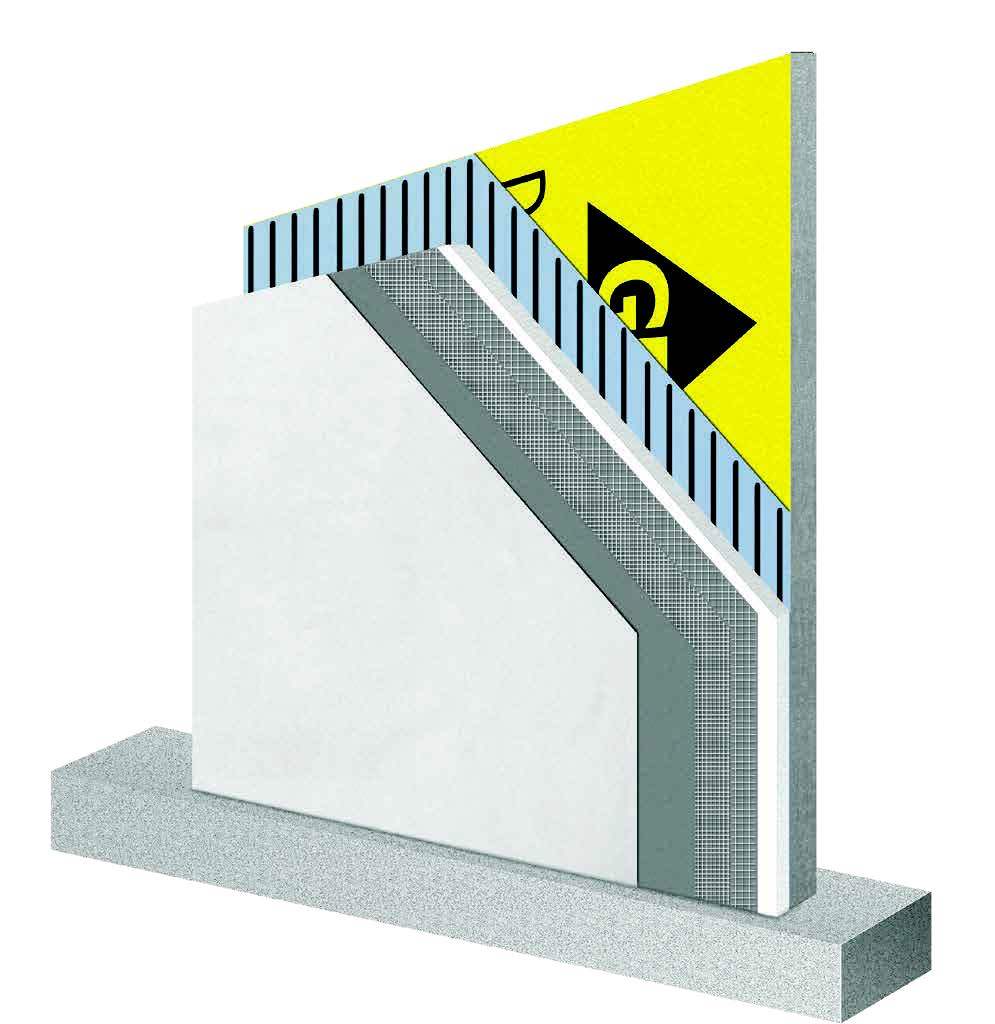

Air and Water Barrier Systems

Master Wall Inc.

The SuperiorShield Building Solutions are a single-source system for air and water protection for your buildings. The products are designed to work seamlessly with one another as part of a comprehensive air and water protection strategy. These fluid-applied air and water barrier systems offer extremely low air leakage ratings with water holdout. The centerpiece of this application is our Rollershield fluid-applied product that easily covers 100 percent of the surface area for complete building protection. Products include moisture-curing liquid flashing, roll/spray grade, trowel grade and high build. For more information, visit masterwall.com/superiorshield.

Rasp for EIFS/Stucco

Demand Products

The Original DuraRasp line of hand rasping tools are not only heavy duty and long-lasting, they are also custom-crafted. The performance of the tool is unmatched, outlasting rasp paper over 100 to 1. The product will give you long-lasting performance and effortless removal of material on EIFS, CI and insulated stucco applications. The products are manufactured in the U.S. Check out demandproducts.com to see the full collection of the rasping tools, including TigerClaw, Smoothie and Edgers.

Premium Finishing Trowels

BEROXpert North America

The Premium Finishing Trowel is just that. Premium. The company’s goal was to provide a trowel that the master plasterers used to use. The tool is designed to have a solid ground plate, all stainless German steel, with broken edges, set and ready to use out of the box. That means no rivets through the plate, Camel Back wood or Comfort Cork handle. For more information, visit BarnabyToolEquipment.com.

Elastomeric Acrylic Finishes

Stuc-O-Flex

The company’s Elastomeric Acrylic Finish provides extreme crack bridging abilities for stucco, concrete, block, cement board and a variety of other surfaces. This durable, color-integrated protective membrane resists fading, dirt pick-up and lasts for decades. The industry’s highest levels of 100 percent acrylic polymer ensures unmatched resistance to surface cracking, unlike standard finishes. An unlimited selection of colors in four distinct aggregate choices create a wide variety of texture opportunities from the heaviest southwest stucco to the more contemporary sand finish. For more information, visit stucoflex.com.

Resin-cast Shapes

Sto Corp.

StoCast is a resin-cast shape that offers the authentic look and feel of wood and brick with superior performance. They can be used indoors, outdoors, on walls and soffits. Lightweight, flexible, customizable and fully tested to comply with the current building codes, including NFPA 285, NFPA 268, ASTM E119 and ASTM E84, they can be applied over a wide variety of systems, such as rainscreen, stucco, cement board or EIFS. This allows it to give design freedom. Resin-cast shapes ensure a tighter building envelope, eliminating the need for fasteners; the shapes are adhered to the substrate, keeping it free of penetrations and allowing for a quick, easy installation. As a lightweight material, the product is versatile, safe and sustainable and offers a lower embodied carbon footprint with reduced transportation needs and structural load in buildings. When used in a continuous system, it keeps a low operational carbon footprint. For more information, visit stocorp.com.

Mechanically Attached Waterproofing Membrane

MFM Building Products

FutureFlash is a mechanically attached waterproofing membrane designed for use around windows and doors in stucco applications. The product may be used in strip in flanges of wood, metal and vinyl windows, or as a flashing membrane where a dependable waterproofing barrier is needed. The product is composed of two high-performance films that are extremely tough and durable, and the rubberized core self-seals around fasteners. This 25-mil product is offered in 6, 9, 12, 18, 24 and 36 inches by 75-foot rolls, and comes with a 10-year warranty when used with FutureFlash Sealant. For more information, visit mfmbp.com/futureflash.

Panelized Systems

Parex USA

The company offers systems and technical support for panelized continuous insulation EIFS or MVS systems that offer many advantages including fast track project scheduling, integrated project delivery, increased QC and value. Panelized systems offer a tremendous range of design flexibility. Panelization and modular construction has continued to grow in popularity in the marketplace. The systems incorporate code-compliant CI assemblies including Parex USA air/WRBs and thin veneer systems. For more information, visit parexusa.com.

Fiber Reinforced Stucco

SPEC MIX

The Scratch & Brown Fiber Reinforced Stucco is a custom blend of cementitious materials, additives, aggregates and alkali resistant fibers meeting ASTM C 926 requirements. The special sand gradation used provides excellent workability and finishing properties for the applicator as well as increases the flexural strength of the wall while reducing cracking and crazing common with traditional field-mixed stucco. The final wall system will produce a non-load bearing, aesthetically pleasing exterior veneer or interior finish on concrete or masonry walls, stud walls or metal buildings. For more information, visit specmix.com/stucco.