While continuous insulation improves wall thermal performance, DuPont's integrated structural insulated sheathing system outperforms traditional assemblies by reducing thermal bridging and preserving more of the designed R-value through advanced Clear Field U-Factor modeling. By Keith P. Nelson

How to Achieve Exceptional

Thermal Performance

xxxxx. xxx

xxxxx

xxxxxxxxx

xxxxxxxxxxxxxxx By xxxxxxxx

h2 - xxxx

h3 - xxxx

H1 headline

Buildings account for about 40 percent of total energy use, much of it tied up in the seemingly basic task of keeping occupants comfortable. Model energy codes, such as the International Energy Conservation Code (IECC) and ASHRAE 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings (ASHRAE 90.1) have been increasing various requirements across climate zones to reduce energy loads and increase efficiency for new construction and major renovations. A primary means of achieving the load reduction is through use of insulation in the opaque portions of a building’s exterior walls.

Insulating materials for exterior walls have historically been installed in between the studs—in the stud cavity—until prescriptive compliance in model codes began acknowledging the significant impact continuous exterior insulation has on limiting the thermal shorts or bridges that occur through a wall by means of conduction. In this article, we share results from studies that show continuous insulation alone may not be enough to ensure a building can achieve the designed level of energy efficiency, along with an innovative solution to solve this challenge.

CI and R-Value Defined

Continuous insulation is defined in the 2024 IECC as an insulation material that is continuous across all structural members without thermal bridges other than fasteners and service openings. To meet the code, design professionals must specify materials with a high insulating value per inch, or R-value. R-value is a material’s thermal efficiency, or ability to resist thermal transfer, as determined in laboratory conditions using the material only.

The Challenge: Energy-Efficient Exterior Walls That Perform as Designed

Simply adding a high R-value product to the exterior wall assembly does not guarantee an energy-efficient building. In a traditional assembly, cladding attachments can penetrate the thermal control layer/CI, short-circuiting the insulation’s ability to block heat transfer. A material’s R-value can often be reduced by as much as 50 percent[1] once placed in a cavity between wood or metal studs. This measurement of the assembly’s R-value is called the effective R-value. Effective R-value includes the thermal resistance of all insulation (both CI and cavity insulation) in a wall assembly, accounting for the effect of thermal shorts caused by stud and framing members.

Is CI the Solution to Designing Energy-Efficient Walls?

Energy codes have addressed the drop in energy efficiency due to thermal bridging by requiring continuous exterior insulation on the external side of wall framing members. But is continuous insulation enough to ensure designed wall R-value can be achieved?

The short answer is no. Traditional insulation materials and construction methods may not prevent increased thermal bridging. This is because cladding attachment sub-framing, furring, clips, fasteners and other conductive components may penetrate the thermal control layer/CI. To truly determine if a wall assembly can achieve designed R-value in the field, we need a more reliable way to measure thermal efficiency.

A Better Measure: Clear Field U-Factor Analysis

Advancements in wall assembly modeling software have enabled consultants and design professionals to look at a given wall assembly and determine much more accurately just how efficient it will be when installed on a building. This modeling is called “Clear Field U-Factor.”

U-Factor is the measure of thermal conductance for an entire wall assembly. Modeling software is used to account for the R-value of all materials in the assembly, the assembly’s effective R-value and the effects additional thermal bridging components (e.g., sub-framing, furring, cladding fasteners, etc.) have on the assembly’s thermal conductivity.

When Clear Field U-Factor modeling is used to measure their thermal conductivity, many traditional commercial wall assemblies have been shown to have a lower effective R-value than designed. This modeling shows that the wall assembly design matters even more than simply using a high-R-value insulation material.

Decoupling Cladding Attachment from Structural Framing Cuts Thermal Bridging

The use of structural insulated sheathing as continuous insulation is a highly effective means to significantly reduce thermal bridging. There are several integrated panel systems on the market that combine insulated sheathing with structural panels. While both the insulation and structural components vary in their efficacy, some have proven to eliminate highly conductive metal sub-girt assemblies, effectively “decoupling” the cladding attachment from the structural framing component of the assembly.

Clear Field U-Factor Modeling of a Decoupled System

One manufacturer commissioned a third-party study by Stantec (formerly Morrison Hershfield) using Clear Field U-Factor performance modeling to evaluate the performance of an exterior wall assembly that incorporates structural insulated sheathing, allowing direct cladding attachment.

Unique to this system is a magnesium oxide (MgO) sheathing fused to an ultra-low-global warming potential continuous insulation layer, creating an exceptionally strong, durable structural panel that allows direct cladding attachment. This quality of the MgO sheathing dramatically reduces the thermal bridging through wall framing that is inevitable with conventional assemblies. Combined with its factory-applied air- and water-resistive barrier, the system significantly reduces conductive heat transfer, resulting in a wall assembly that preserves maximum effective R-value. Moreover, the MgO-infused sheathing enables NFPA 285 approval and up to 2-hour UL fire-rated assemblies.

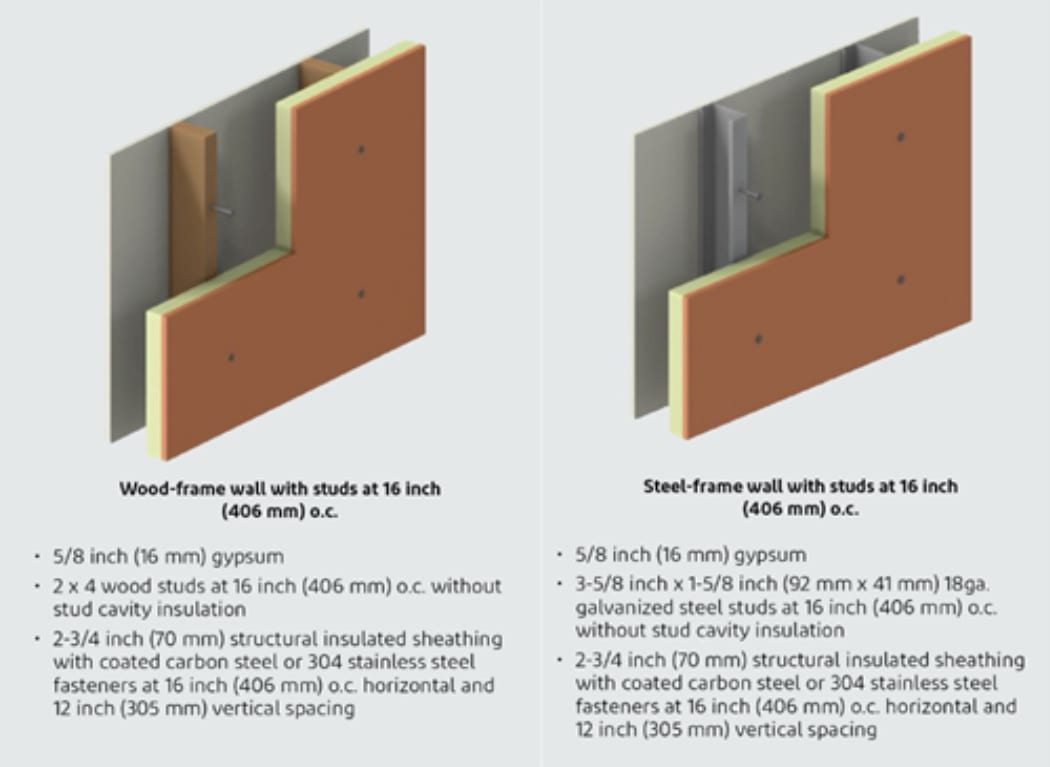

Components of the wood- and steel-framed assemblies Stantec evaluated are outlined here.

Figure 1: Components of Evaluated Wall Assemblies

Clear Field U-Factor Results

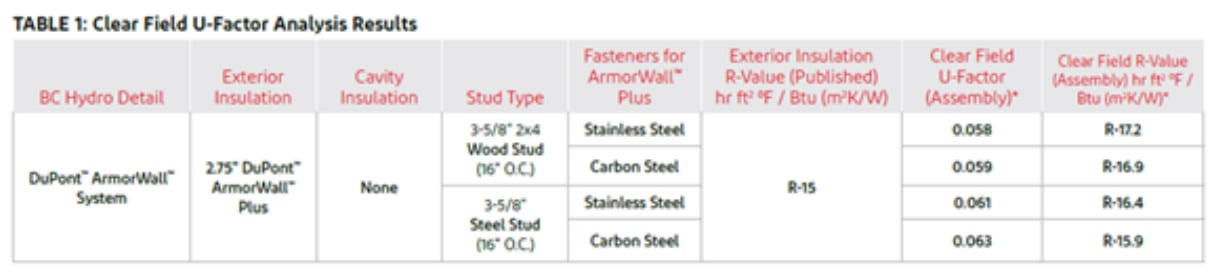

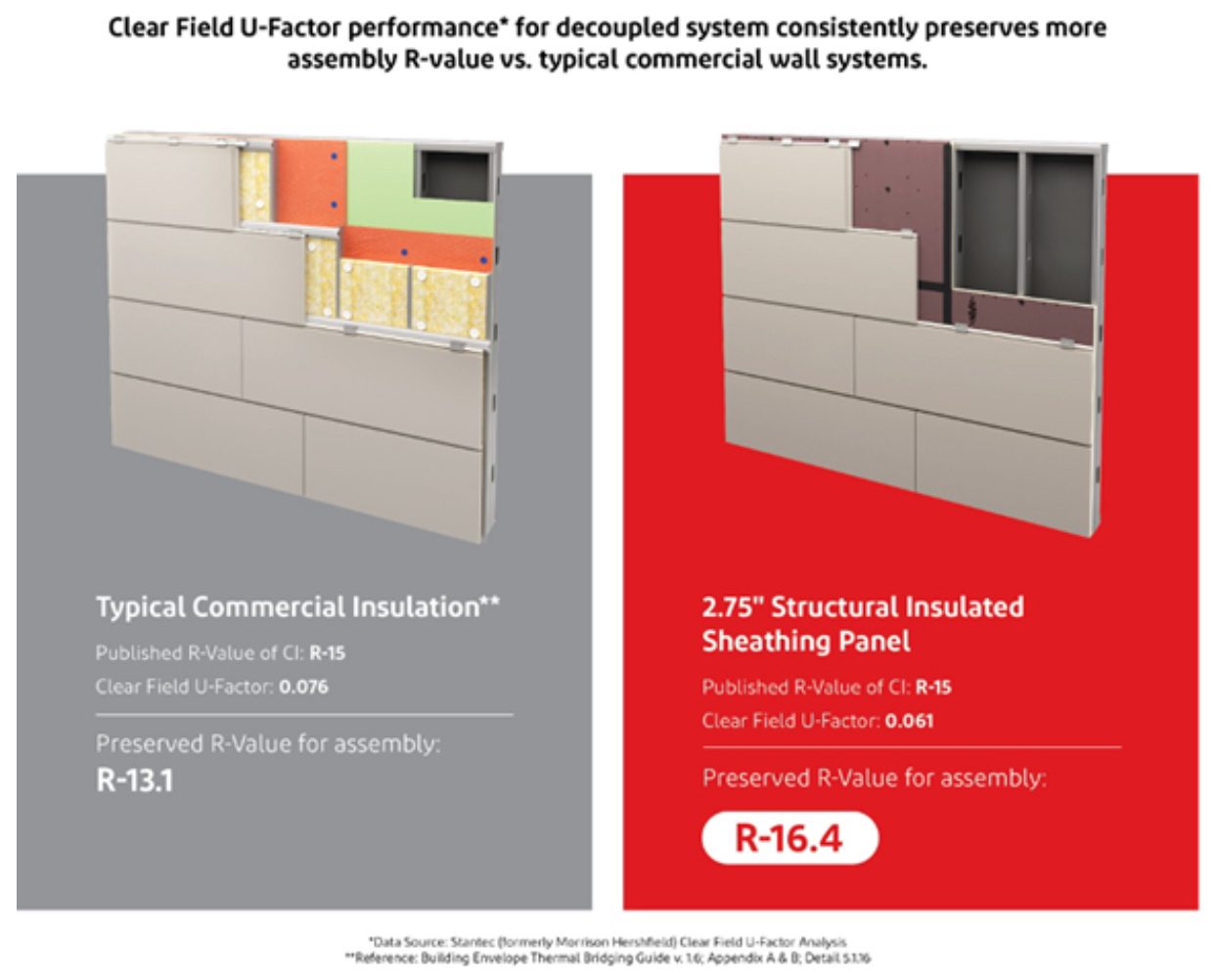

Stantec systematically compared commercial wall system assemblies, with a specific focus on their Clear Field U-Factor performance. The data shown in Table 1 and Figure 2 validate that assemblies incorporating the decoupled system demonstrate Clear Field U-Factors that preserve more of the designed R-value of the wall assembly. In contrast, comparable typical commercial wall assemblies demonstrated greater loss of designed R-value once the entire wall assembly U-Factor was assessed.

Table 1: Clear Field U-Factor Analysis Results

*See Figure 2 for example of assembly details.

Figure 2: Clear Field U-Factor performance* for decoupled system consistently preserves more assembly R-value vs. typical commercial wall systems.

Key Findings: Decoupled System Reduces Thermal Bridging and Preserves More Designed R-Value

Stantec’s comparative analysis demonstrates that certain decoupled assemblies exhibit superior performance in minimizing thermal transmittance, outperforming many conventional assemblies by yielding a lower Clear Field U-Factor. When installed on commercial buildings, these integrated assemblies can help enhance energy efficiency by significantly minimizing conductive heat loss and can also help to significantly reduce operational costs over the building’s lifespan. Combined with an air- and water-resistive barrier component, structural performance, and fire resistance, an integrated wall assembly can help enable flexible design and simplified construction. Overall, prioritizing assembly U-Factor over individual component R-value holds great promise in developing more cost-effective building practices and innovative solutions that preserve maximum effective R-value.

Integrating an exterior wall assembly with structural insulated sheathing into commercial buildings can help project stakeholders meet energy codes, achieve higher performance ratings and deliver a solution sooner to their clients, making it a strategic investment for the future of the commercial construction industry.

Footnotes:

*For Clear Field U-Factor Analysis and a complete comparison between decoupled assemblies and many other typical commercial wall assemblies, refer to the Building Envelope Thermal Bridging Guide v.1.6 as prepared by Stantec and published by BC Hydro; find above comparison in Appendices A & B, Detail 5.1.16

**The effective R-value of 18.2 includes approximately R-0.56 for exterior gypsum sheathing, which is not needed in a decoupled assembly

References

- Source: ASHRAE 90.1-2022, Table A3.3.3.1.

Images courtesy of DuPont.

Keith P. Nelson joined DuPont in January 2023 with over 20 years of industry experience leading building enclosure consulting for design and construction projects across the US and internationally. He is a licensed Architect in multiple states and joined DuPont with strong experience in building science, building enclosure forensics, enclosure commissioning, field performance testing, and is an industry leader in NFPA 285 compliance education. Keith leads and participates in multiple standard development organizations, including ICC 1125, ASHRAE 90.1, ASTM E06, and ASTM E05 and was elected to the ABAA Board of Directors in June 2024. He holds a Bachelor of Science in Architecture and a Bachelor of Science in Environmental Design from Ball State University in Muncie, Indiana.