The Right Channels

A California insulation contractor utilizes the benefits of trade associations and networking for continued growth. By John Wyatt

Industry Affiliates

- Insulation Contractors Association of America

- Insulate America

- American Subcontractors Association

- Firestop Contractors International Association

- Air Barrier Association of America

Dittemore Insulation Contractors Inc. specializes in commercial insulation from its home-base of Anaheim, Calif. The company has multiple divisions that cover the following: state and federal public works, K-12 and higher education, healthcare/hospital, tenant improvement, and high-rises. The company employs 110 people.

Dittemore was founded in 1968 by Don and Dave Dittemore. The company began as Dittemore Brothers but changed names due to an ownership switch in 1998. In 2018, its current President Jeff Baxley and his wife Sara took over as owners. However, the name was such a staple in its region that they retained the name.

“I started off with a fresh clean slate in 2006 without any construction background,” says Baxley. “Oddly, I came from the finance/banking field with experience in mortgages. My love for numbers and extreme competitiveness made construction a great fit. I was brought up among family businesses and knew that is where I wanted to be.

Seeing my parents run a business left a lasting impression on my life and I have enjoyed passing the same experience to my children. In the beginning, I attended the Insulation Contractors Association of America (ICAA) Trade Show and it opened my eyes to how large the industry is. This was the first time I met Michael Kwart [who is the Executive Director of the organization and also serves as a W&C Editorial Advisory Board member]. He set up seminars and training that greatly encouraged my involvement in the industry. The association members are the best of the best, and I highly recommend the association to anyone that isn’t a member.”

Dittemore’s specialties are commercial insulation, fire-stopping/fireproofing, and weather barriers. The insulation is the company’s core line that covers thermal insulation, acoustical insulation, spray foam insulation, and rigid board insulation. Its geographic reach covers the southern half of California. But according to Baxley, the contractor has gone outside of these areas for the right project with the right trade partner.

A Blessed Business

According to Baxley, Dittemore is in a good position. “Since [I have taken over in] 2018, we are in our fourth consecutive year of 50 percent sales growth. We’ve been blessed to have the best trade partners we could ask for to support this pattern. They were a key factor in providing the channels for growth.”

As of the present time, Dittemore is going strong and stable. According to Baxley, the opportunities are abundant when the contractor looks in the right place. He says changes in the market are definitely taking place, from the products used to the increasing project size.

“The overall construction climate has become much more aggressive with risk higher than I have ever seen before. As with all construction materials, our business has experienced pricing pressure due to increased costs on energy pricing, raw materials, and overall inflation,” Baxley says.

“Our approach is to find the opportunity when things change. Change has always treated us well, even though we might not see it right away. I highly doubt we will see material demand lighten up as we go into 2022. If anything, it’s going to ramp up and cause more strain. Our supplier Johns Manville has been an exceptional partner and has supported our material needs through these tougher times.”

According to Baxley, the constant changing environment makes his position very interesting/rewarding. After all these years, he says, the company has yet to see identical days. Each day has its challenges, and Dittemore always ends the day with solutions. It takes quite a bit of creativity to work with multiple owners and general contractors. Each has different requirements/needs and the Dittemore team does an exceptional job delivering to meet their expectations.

But to Baxley, what is the hardest aspect of the job?

“Honestly, we’ve had two main challenges this year: The first being the balancing act of managing a business through COVID-19, which was the hardest aspect we never saw coming. With the State of California abruptly shutting down businesses, it put our management team into overdrive. The second challenge was balancing material shortages and allocations from the manufacturers cutting back access to material.”

“We moved our operation to a larger facility last year that allowed us to order ahead of the rush and gave us the ability to use warehouse stock to ease the pain,” he continues.

“By no means was this an easy task—but we have the right Dittemore team members that were able to pull this off. Our main supplier was also instrumental in working with us to ensure supply during these tough times.”

Project Profile

The interior wall design for the insulation and fire-stopping was the toughest challenge, says Baxley. Due to the seismic requirements of Southern California, it was necessary to provide substantial deflection/movement for the wall where it meets the deck above.

As with most projects, form and function can be a delicate balance. This led the company to four areas of concern for the walls:

- The fire-stopping system for the fire-rated walls required a massive 1½ inch deflection;

- The system needed to meet the strict acoustical requirements of the hotel;

- The system had to be aesthetically pleasing and unnoticeable once installed, and;

- Minimal cost impact;

Now there are multiple assemblies that can accomplish a few of these design elements but finding one all-encompassing system that covered all aspects posed the challenge. The Dittemore team worked closely with Hilti for the design elements. The tool manufacturer’s design team provided a solution Dittemore settled on by using Hilti’s Top Track Seal to accomplish all four elements of movement, acoustics, aesthetics, and cost.

“It was a positive experience where the manufacturing team led educational meetings and provided all the support necessary. We were able to deliver the right installation with no cost impact. This makes for a perfect client experience,” says Baxley.

As for the ceiling design, Dittemore ran into a scenario where the podium parking structure created a thermal gap where the hotel sits on top of the parking structure. Not only did this pose a potential thermal inefficiency under the footprint of the structure, but it also caused excessive noise transfer from the parking area to the hotel lobby. Just like the wall design, the aesthetic requirements of the owners played a key role in the design.

“Our solution was to use K-13 thermal/acoustic spray insulation by International Cellulose Corporation. This an excellent product that created the right ceiling finish texture along with the thermal and acoustical properties the architect desired,” says Baxley. “Another aspect that makes this product shine is its ability to seamlessly work around piping, ductwork, and any other possible obstruction. We highly recommend this system when multiple needs must be met on high profile jobs.”

Johns Manville, International Cellulose Corporation and Hilti Fire-stopping products were used on this projectp

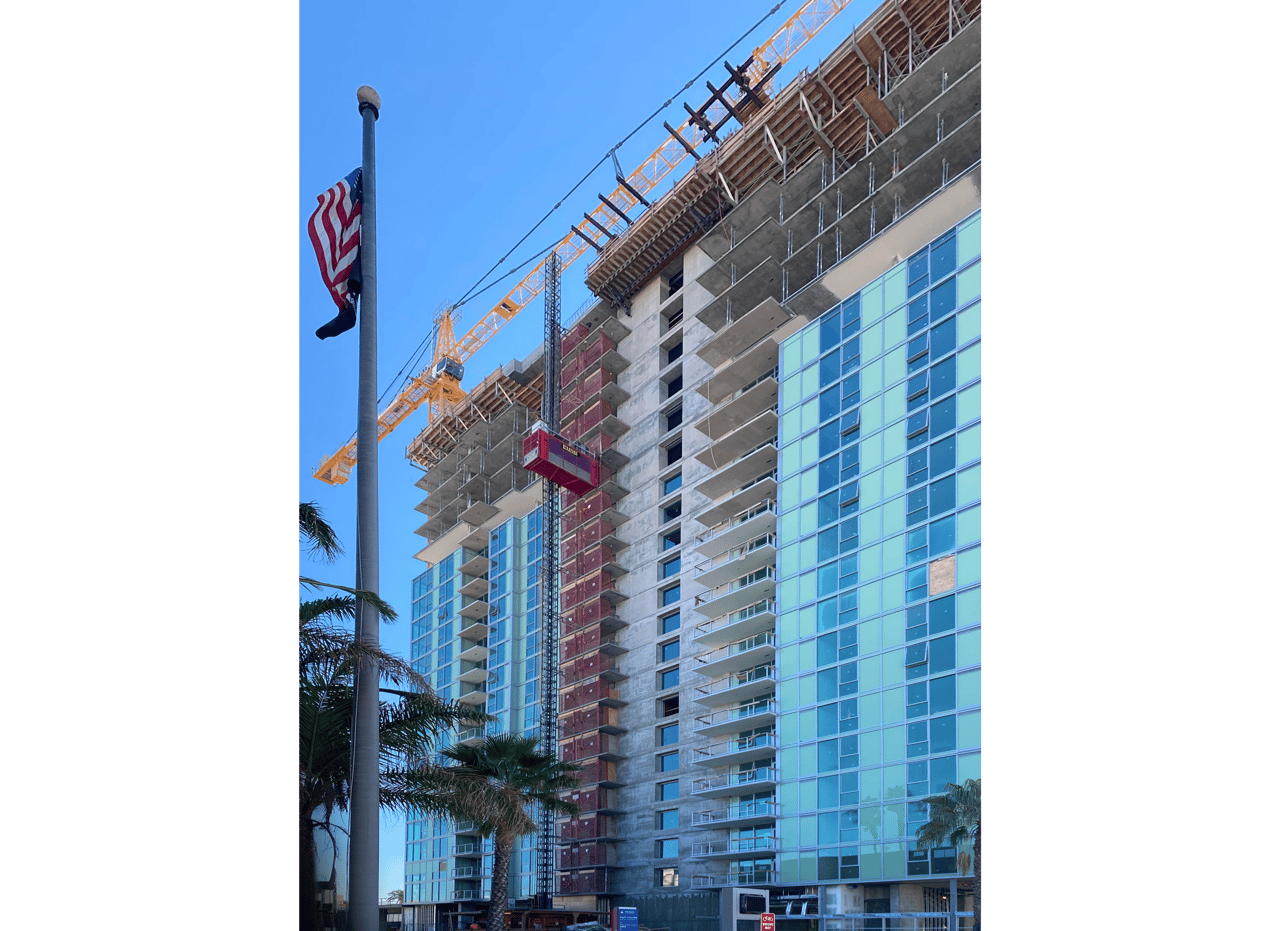

Project: Moxy/AC Dual Brand Hotel

Location: Los Angeles

Architect: Gensler

Builder & General Contractor: Suffolk Construction,

Owner: Lightstone DTLA LLC

The Moxy/AC Dual Brand Hotel project in Downtown Los Angeles is a mixed-use hotel with retail space directly across from the LA Convention Center and the Staples Center. Its geographical location puts it in the heart of the Los Angeles downtown revitalization.

The products used by Dittemore Insulation Contractors were thermal insulation, acoustical insulation, rigid insulation, fire-stopping systems and acoustical spray insulation

A Serious Forecast

The company’s backlog/future projects are looking solid. Between political and pandemic pressures, Baxley says, he feels project owners are reluctant to release projects causing delays. Owners have a false sense that material availability and pricing pressures will ease. If they wait, they think this can bring projects more in line with their outdated budgets. Once these projects are released to move forward, the industry/Dittemore may see the market inundated with work. This will further strain the material and labor market. Dittemore will continue to have “qualified” labor shortages. Baxley emphasizes “qualified” because finding the right replacements for the retiring work force is a constant challenge. There is a lot of crew available but it does not always mean they are right for the job.

Baxley says his long-term goals are continued growth by building relationships with great partners. This has been the core value in the subcontractor’s organization. Anyone can land jobs by just being the low bidder he says, but the real successes are built on a foundation of lasting relationships with great people.

“Hands down, it’s our service and expertise,” says Baxley in regards to what makes Dittemore among the best. “As building science changes to improve our carbon footprint, the data and informational support is key to creating an insulation system that delivers. This is impossible without product knowledge. Our service is top notch and can support any size project. This gives us the versatility to meet whatever our trade partners require of us.”

“Construction is a people-business and requires the right team to build the relationship and to get the job done. Our success is the result of all the hard work our team invested.”

But what happens when hard times hit next, what will the company do different from the last recession?

“From the last downturn, we considered all the things that did work and the things that didn’t work,” says Baxley. “Our most successful approach in the tough times was continuing to build and maintain our relationships, while the least successful was getting caught up chasing the cheap work with questionable contractors. Since construction is a cyclical industry we can count on hard times at some point, but we will do our best to be as prepared as possible.”

Finally, Baxley says his company’s greatest achievement is assembling a team that works together seamlessly. In his words, finding people with a solid work ethic along with a drive for success is becoming increasingly difficult.

“To have a team where personalities work together is priceless. We would not have our success without our people.”