Urbanization and Indoor Air Quality:

How Continuous Insulation Improves Building Efficiencies

How can the AEC community create buildings and spaces that promote improved IAQ and occupant wellness? By Jen Frey

Global megatrends like rapid urbanization, shape our world and challenge us to examine our future in new ways. It's estimated that by 2050, almost 70 percent of the world's population—approximately seven billion people—will live in cities.1 As of 2021, North America was the most urbanized continent worldwide.2 If carefully considered, urbanization can have a positive outcome providing opportunities for growth, sustainable development, and social integration. However, without conscientious planning, urbanization can increase congestion, noise, and air pollution—both indoors and out.

For decades, architects, engineers, contractors and manufacturers have been working to address rapid urbanization by reexamining building design for performance, efficiency, sustainability, and occupant health, comfort and safety. One critical area of consideration continues to be indoor air quality. As city populations grow and bring with them the probability of increased air pollution, how can the Architecture/Engineering/Construction community best create buildings and spaces that provide improved IAQ and promote occupant wellness?

Air Pollution in Urban Areas

Air pollution is a significant threat to the health and wellness of people of all ages. According to the World Health Organization, “In 2019, 99 percent of the world population lived in places where the WHO air quality guideline levels were not met.”3 A CDC study, which assessed the differences between rural and urban air quality, found that air quality improves as areas become less urbanized, with pollutants more concentrated in cities.4 These results show that greater awareness and intervention are needed for people living and working in cities to improve the air they breathe.

Pollutants from the outside can easily get into a building through cracks in walls, floors and ceilings, and of course, windows and doors. On the interior, furniture, flooring, and other building materials can be another source of indoor air pollution, as can heating and cooling systems and cleaning products to name a few.

On average, Americans spend approximately 90 percent of their time indoors. According to studies conducted by the United States Environmental Protection Agency, “human exposure to air pollutants indicate that indoor levels of pollutants may be two to five times—and occasionally more than 100 times—higher than outdoor levels.”5

Poor indoor air quality is not only harmful to the health and comfort of building occupants but can also negatively affect performance at work, learning in educational environments, or healing in healthcare settings. While there has been a long-term focus on providing improved indoor quality, in a post-COVID society, people are even more acutely aware of the quality of the air they breathe, requiring the AEC community to revisit product specifications.

Controlling Air Quality

Architects and builders have several tools at their disposal for controlling air quality. One is airflow, or how regularly the indoor air is circulated and refreshed. Another is climate control, which includes indoor temperature and humidity levels that are fundamental to people's health and comfort. Construction materials are often overlooked tools that must comply with building codes and protect from the outdoors without producing harmful byproducts.

Many construction materials contain volatile organic compounds, which are emitted as gases and often perceived as odors when found in high concentrations. VOCs can have a wide variety of adverse health effects ranging from eye, throat, and nose irritation to nausea or even damage to the central nervous system.

Ideally, the materials selected will be there throughout the building’s life-cycle, so it's critical to choose materials that won’t diminish the indoor air quality. It is also important to understand the overall environmental impact of materials chosen, including potential outdoor pollutants. The construction community is gaining a greater understanding of the impact of certain VOCs on global warming, including the different contributions of various rigid continuous insulation products used in building envelopes. This goes well beyond the obvious observation that less energy used means less pollution from heating and cooling systems.

Polyisocyanurate (polyiso) rigid foam core insulation is formulated with a blowing agent that does not contain CFCs, HCFCs (or HFCs), and is manufactured with zero Ozone depletion potential and negligible global warming potential. Industry-leading manufacturers offer polyiso that is available with UL GreenGuard Gold Certification, a rigorous third-party standard with strict VOC emission requirements, for projects designed with sensitive populations in mind, such as school and healthcare facilities. Additionally, some manufacturers have introduced non-halogenated insulation products to meet certain environmental specifications set by governments or companies. These products can carry the International Living Future Institute’s Declare label, a brand promise for building products.

The Declare label informs consumers about a product's composition, life expectancy, and other critical information impacting environmental health. Architects and specifiers should look for polyiso insulation with GreenGuard Gold Certification or the Declare label to ensure what goes inside the wall doesn’t contribute to poor indoor air quality.

In a recent report written by the Applied Building Technology group titled “Healthy Buildings and the COVID-19 Pandemic,” the authors provide a straightforward explanation of how climate control measures can help contribute to healthy indoor air quality. The report states, “Indoor environmental conditions for temperature and humidity that tend to be optimal for human health and comfort also tend to be less than optimal for many types of pathogens.”6

According to the report, many viruses persist in colder, dryer conditions and become inactivated more quickly within a “sweet spot” of 40 to 60 percent indoor relative humidity. This range is narrower than the long-standing "healthy zone" of 30 to 60 percent RH. Designing to a tighter standard addresses better indoor air quality and occupant comfort in all seasons. A well-insulated building envelope allows energy that would be used for heating or cooling to instead be used for increased air circulation, humidity control and filtration.

As energy efficiency standards have evolved, building codes require the addition or increase of continuous insulation to reduce thermal bridging. Continuous insulation enables HVAC systems to function more efficiently, reducing operating costs.

However, not all jurisdictions have adopted the most recent building code and may be using outdated insulation specifications. The AEC community can help by specifying the proper R-value referenced in the latest code version in building designs beginning with a continuous insulation that offers superior thermal performance, like polyiso. Polyiso continuous insulation has one of the highest R-values per inch to allow for a thinner wall profile without sacrificing performance or interior space.

Depending on a project's needs, polyiso foam board insulation is available in semi-permeable and vapor-impermeable product options. Thus, the builder can utilize continuous insulation without being constrained on interior vapor barrier selection or other assembly design preferences.

Moisture and IAQ

When properly installed, polyiso continuous insulation can also be an effective water resistive barrier preventing water intrusion at the outermost position within the wall assembly. As a result, a separate WRB is not necessary, thus reducing installation time as well as material and labor costs. By simplifying the wall design, builders can mitigate the chance for failures without giving up overall performance.

Particularly in cold climates, the exterior wall temperature can have a big impact on vapor drive and condensation within assemblies. When water vapor condenses, potentially at water sensitive layers, the likelihood of damage and other undesirable effects increase, including impact on IAQ. By isolating the internal assembly layers from temperature extremes, continuous insulation prevents water vapor from reaching its condensation point, effectively short circuiting the potential for damage and call backs. Mitigating the temperature difference throughout the wall layers by reducing moisture drive also reduces moisture cycling in the framing; an intrinsic benefit often overlooked by those who focus on R-value alone.

A Step Beyond

In addition to incorporating moisture resistance, a practical wall assembly design should ensure occupant comfort and address environmental requirements like energy efficiency, thermal performance, and durability.

Creating safe, comfortable, and healthy indoor spaces requires a coordinated approach during the design and construction phases to meet long-term performance plans. As city populations continue to grow and a broader population becomes more attuned to indoor air quality, more people will seek a higher standard of building design. By selecting best-in-class building materials that meet or exceed building codes and performance specifications, like polyiso continuous insulation, improved indoor air quality can be attained with minimal changes to how we build today.

References

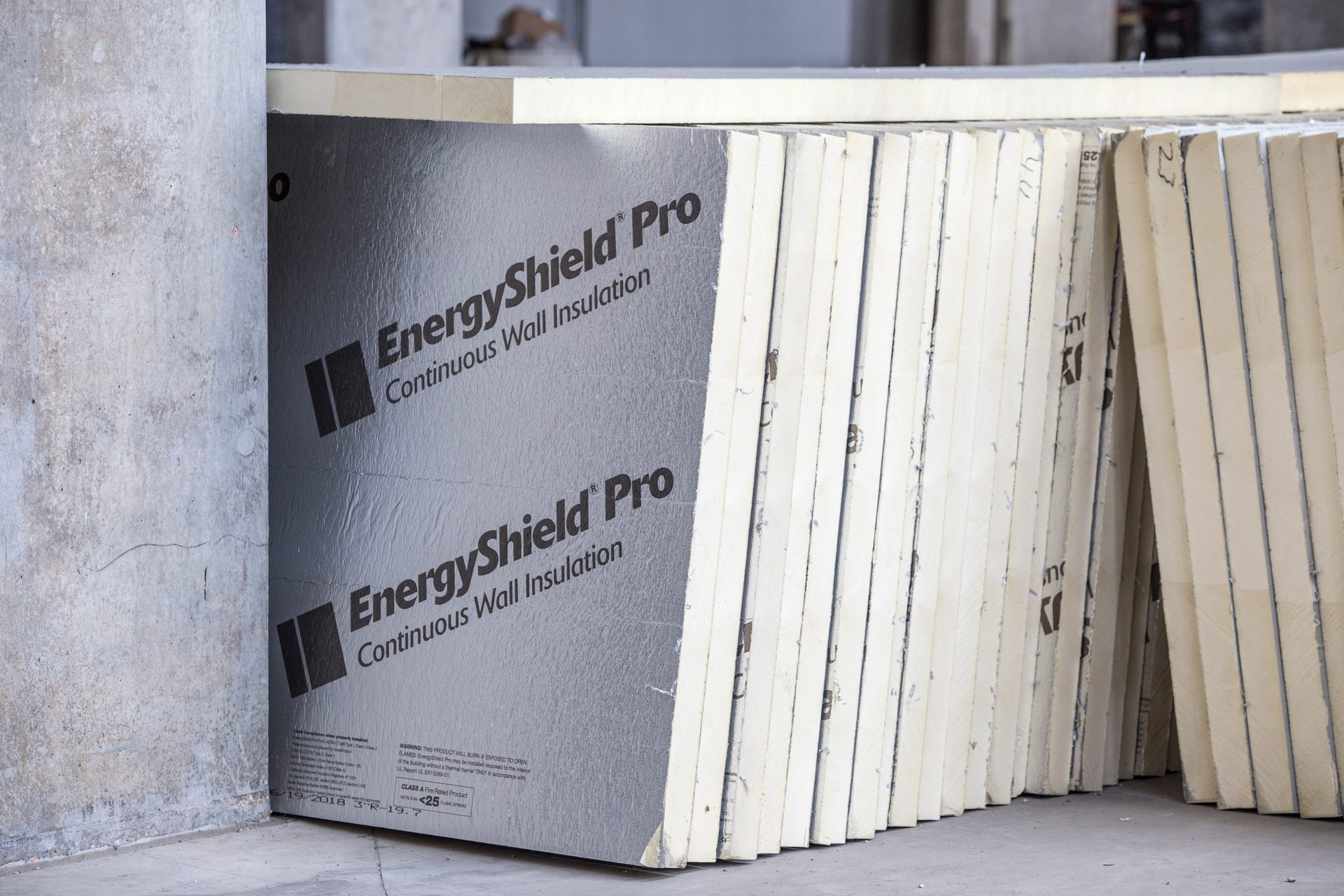

Images courtesy of Atlas Roofing Corp.

Jen Frey is the senior product manager for Atlas Roofing Corporation’s Polyiso Roof & Wall Insulation division and has more than 15 years in building materials representing brand leaders in high growth product categories, including roofing and building envelope. She has successfully launched innovative product solutions meeting customer needs and has been co-named in six patents.